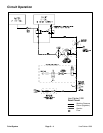

Paint Circuit

The Line Painter 1200 paint circuit uses a positive dis-

placement diaphragm pump to move paint from the

paint tank to the spray nozzle. The spray pump is a self–

priming diaphragm pump that has a dry crankcase.

The engine drives the spray pump indirectly through pul-

leys and a V–belt. The spray pump belt is always ten-

sioned by a backside idler pulley so the pump is being

rotated whenever the engine is running.

When the pump is rotated, the downward stroke of the

pump’s diaphragm creates suction to allow fluid (paint)

to be drawn from the paint tank to the pump via hoses,

a ball valve (in the paint position) and a 40 mesh screen

filter. Pump design prevents fluid from being pumped

back into the suction line.

Once to the pump, the fluid (paint) is pushed by the up-

ward stroke of the pump’s diaphragm to the pressure

side of the spray system through hoses, control valves

and the spray nozzle. Pump design prevents fluid from

being drawn back into the pump. Maximum pressure in

the system is limited by an adjustable relief valve located

in the pump.

An adjustable pressure regulator is used by the operator

to set paint circuit pressure on the Line Painter 1200.

Flow in excess of the regulator setting is directed back

to the paint tank via a ball valve (in the paint position).

This return flow is used for paint tank agitation. An op

-

tional pressure gauge (if equipped) indicates system

pressure.

A mechanically actuated spool valve is used to turn the

spray nozzle on/off. Spool valve shift occurs when the

operator depresses or releases the paint control lever.

Line Painter 1200 Page 5 – 5 Paint System

Paint

System