Stylus C40UX/C40SX/C20UX/C20SX Revision A

Operating Principles Overview 27

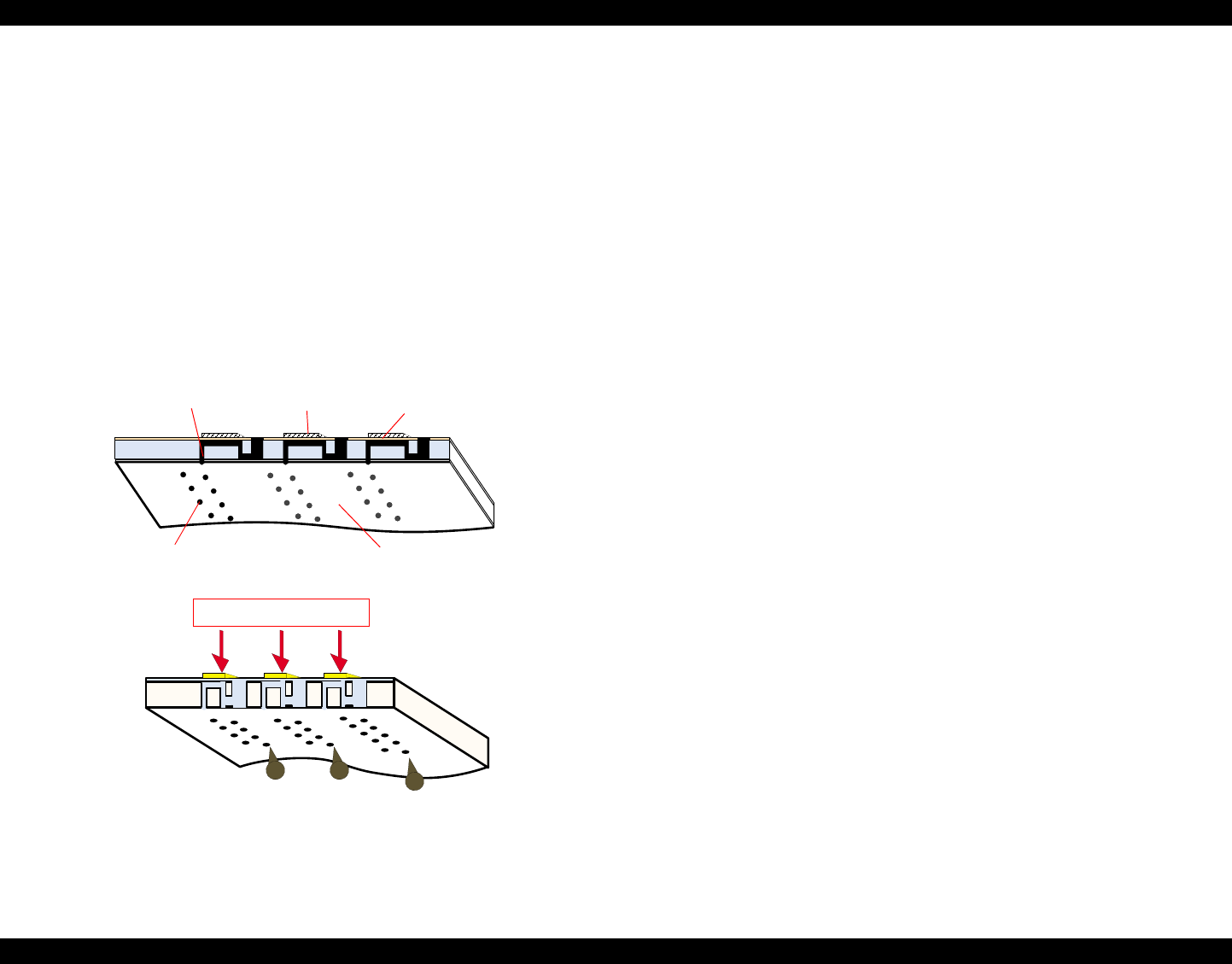

2.1.2.1 Printing Process

This section explains the process in which the printheads of On-Demand inkjet printers

eject ink from each nozzle.

1. Normal State:

When no printing signal is sent from PC, or no PZT drive voltage is applied, PZT

does not change shape, therefore PZT does not squeeze the cavity. Ink pressure

inside the cavity is kept normal. (Refer to Figure 2-3.)

2) Ejecting State:

When the print signal is output from the C413MAIN/B board, IC (Nozzle

Selector) located on the printhead unit latches data once by 1-byte unit. An

appropriate PZT latched by the nozzle selector is pushed into the cavity by the

common voltage applied from the main board. By this operation, ink stored in the

cavity spurts out from nozzles.(Refer to Figure 2.1.2.2.)

Figure 2-3. Printhead printing process

2.1.2.2 Printing Method

For print dot system, Stylus C40UX/C40SX/C20UX/C20SX has the following two

kinds of printing modes.

Multiple shot printing

Variable dot printing

The above two printing modes are automatically selected depending on the media and

the resolution setting of the printer driver. The following explains each printing mode.

Multiple shot printing

This printing mode is developed to improve the print quality on plain paper or

transparencies in low resolution. The multiple shot printing mode uses normal dot

and the number of dot shots varies from 1 shot to maximum 4 shots depending on

the print data to enable sharp image output even in a low resolution.

Variable dot printing

This printing mode is developed to improve the print quality on exclusive paper.

This mode is basically the same as variable dot printing mode used on other

products /; micro dot, middle dot, and large dot compose this mode. Print dot size

varies according to print data and this mode enables even sharper image output on

exclusive paper.

Ink Path

PZT

Ink Cavity

Nozzle

Nozzle plate

PZT drive voltage