Stylus C40UX/C40SX/C20UX/C20SX Revision A

Maintenance Overview 96

6.1.2 Service Maintenance

If print irregularity (missing dot, white line, etc.) has occurred or the printer indicates

“Maintenance Error”, take the following actions to clear the error.

Head Cleaning:

The printer has a built-in head cleaning function, which is activated by operating

the control panel.

Confirm that the printer is in stand-by state (the POWER indicator is not blinking),

and hold down the Error Reset SW on the control panel for more than 3 seconds.

The printer starts the cleaning sequence (The POWER indicator blinks during the

cleaning sequence).

Maintenance Error Clear:

Ink is used for the operations such as cleaning as well as printing. Therefore, the

printer wastes certain amount of ink and drains it into waste ink pad, while

counting the amount of the waste ink. Once the amount of the waste ink reaches

the predetermined limit, the printer indicates “Maintenance Error” and the waste

ink pad should be replaced.

Overflow Counter Limit:

Overflow Counter (Protection Counter A) >=8350

Timing for Replacing the Waste Ink Pad:

When the total amount of the waste ink reaches the predetermined limit, the

LED indicates “Maintenance Error”.

Also, during repair servicing, check the ink counter along with the firmware

version, ink counter, select code page, nozzle check pattern on the status

printing sheet. If the ink counter value is close to its limit, notify your

customer and recommend that the waste ink pad be replaced (If the waste ink

pad is not replaced at that time, there is a possibility that “Maintenance Error”

will occur soon after the printer is returned to the customer). Once you have

the confirmation of the customer, replace the waste ink pad.

Replacement Procedure: Refer to 4.2.3 Waste ink pad removal

After the Replacement:

Reset the Overflow Counter (Protection Counter A) : Refer to 5.1.12

Protection counter check

6.1.3 Lubrication

The characteristics of the grease have great affects on the mechanical function and

durability, especially does the characteristics about temperature environment. The type

and amount of grease used to lubricate the printer parts are determined based on the

results of internal evaluations. Therefore, be sure to apply the specified type and

amount of grease to the specified part of the printer mechanism during servicing.

C A U T I O N

Never use oil or grease other than those specified in this

manual. Use of different types of oil or grease may damage the

component or give bad influence on the printer function.

Never apply larger amount of grease than specified in this

manual.

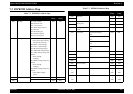

Table 6-1. Specified Lubricants

Type Name EPSON Code Supplier

Grease G-46 1039172 EPSON

Grease G-58 T.B.D EPSON