Page 6-12

Section 6. Replacement Procedures

SATO CL608e/CL612e Service Manual

PN 9001079

Rev. B

The Stepper Motor is used to transmit motion to the print mechanism for precise

print positioning. The stepper motor transmits torque to the label feed roller, the

platen roller, the ribbon feed roller, and the ribbon rewind spindle via a series of

toothed timing belts and gears.

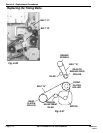

REMOVE (3)

MOUNTING SCREWS

Fig. 6-16

Fig. 6-17

DETACH CONNECTOR

FROM CIRCUIT BOARD

STEP PROCEDURE

1. Switch the printer OFF and disconnect the power cable.

2. Remove (3) screws holding the left side cover to the

printer. Raise the access door and loosen the (2) screws

on the inside top of the printer. Lift off the left side

cover to expose the main PCB. Fig. 6-1

3. Remove (3) mounting screws holding the stepper motor

to the frame. Detach the motor from the belt. Fig. 6-16

4. Detach the motor cable connector from the main circuit

board. Fig. 6-17

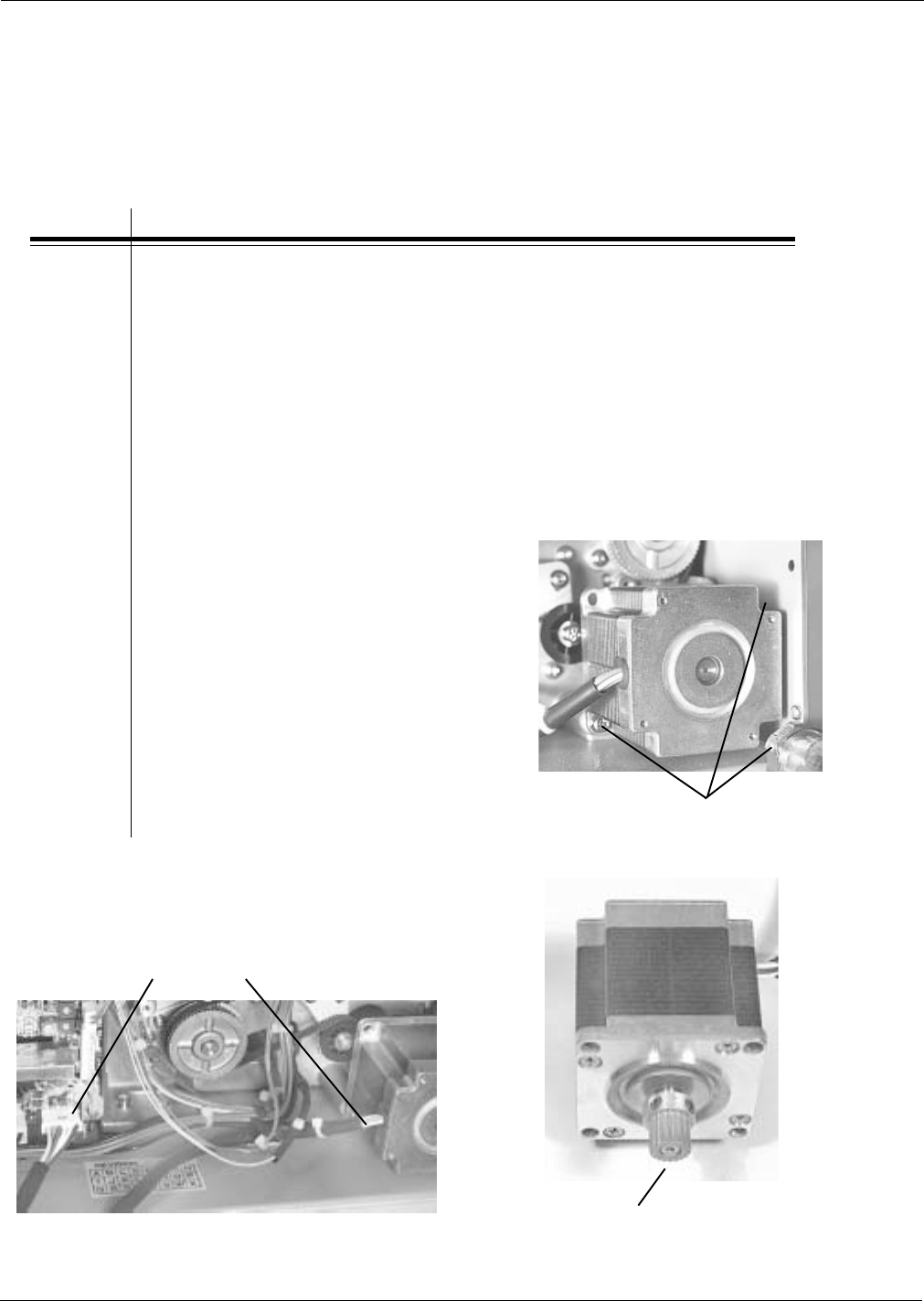

5. Remove pulley unit from old

motor and inspect for wear.

Replace if necessary before

reinstalling. Fig. 6-18

6. Install replacement motor and

belt. Belt will self adjust. Refer to

Section 5.8. Attach motor cable

connector to main circuit board.

7. Replace the left side cover and

reconnect the power cable.

Fig. 6-18

6.5 Replacing the Stepper Motor

REMOVE PULLEY FROM OLD

UNIT AND TRANSFER OR

REPLACE IF NECESSARY