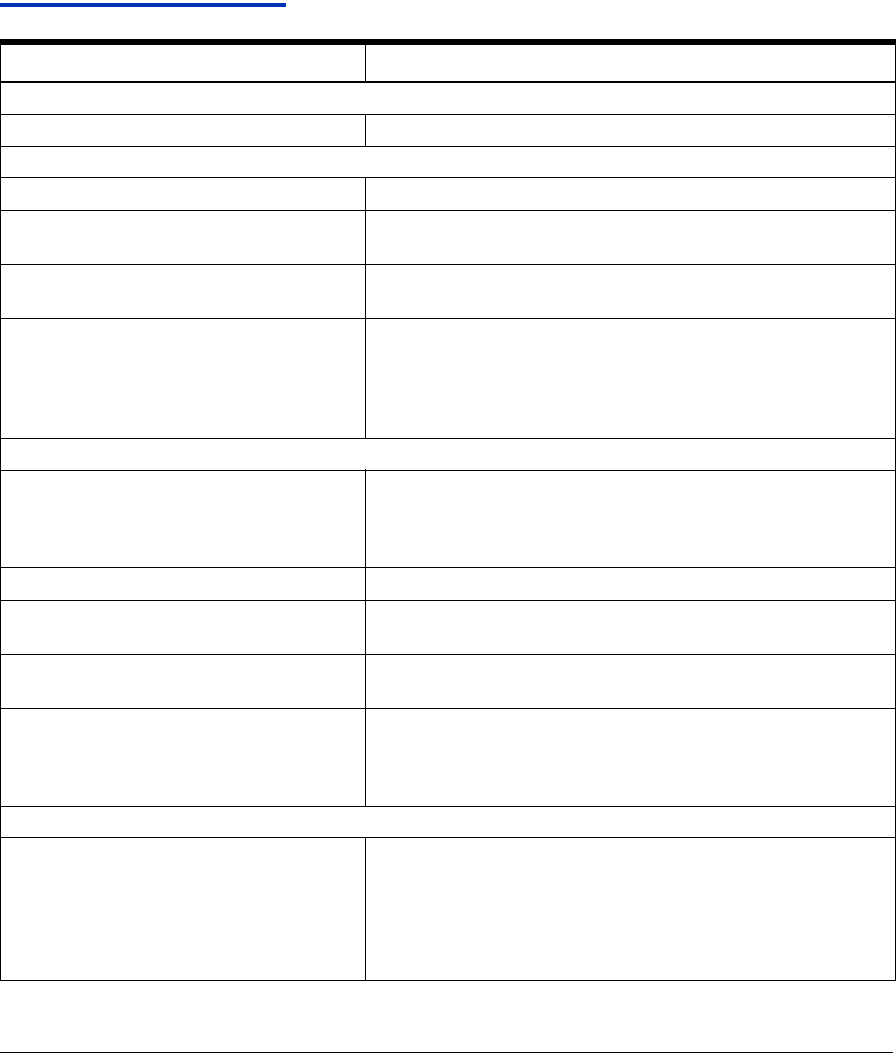

6-2 Maintenance Schedule

Maintenance

Schedule

Task Description

Interval: Daily

Daily Startup Procedure See “Daily Startup” on page 1-6.

Interval: Weekly or as needed

Clean media drive belt and encoder See “Clean the Media Drive Belt and Encoder” on page 6-4.

Clean carriage rail and bearings (page 6-8) Inspect for dust buildup, clean if necessary (see “Clean the Rail

and Bearings” on page 6-8).

Clean the carriage encoder strip Inspect for dust buildup, wipe if necessary with plain water.

Encoder must be fully dry before printing.

Cured ink buildup on the encoder strip cannot be removed with-

out damaging the encoder strip. Clean ink spills immediately. If

cured ink buildup on the encoder strip causes printing errors,

contact your Authorized Service Provider or Technical Services

for a replacement.

Interval: As needed

Clean printheads See “Checking Jet Health” on page 2-23.

To recover jets with a purge, see “Recover Missing Ink Jets”

on page 6-11.

Clean quartz windows See “Clean the Quartz Windows” on page 6-20.

Clean ionizer bar The ionizer bar should be cleaned as needed to maintain its

effectiveness. See “Clean the Ionizer Bar” on page 6-22.

Clean media rollers Uncured ink that has been rolled over by the media rollers can

be cleaned with a paper towel and isopropyl alcohol.

Drain the compressed air

condensate reservoir

Condensate from the compressed air collects in a reservoir

attached to the pressure gauge at the shop air connection. This

resevoir should be checked occasionally and drained when nec-

essary. See page 1-3 for location.

Interval: At control panel warning

Replace ink filters See “Replace Ink Filters” on page 6-15.

Replace all four filters as a set, to prevent ink pump failure. The

control panel will display a Warning message when 20 liters of

ink have passed through the set of filters. You may continue

printing past this point, but printhead fill errors may occur.