Introduction to Variable-Frequency Drives

Getting Started

1–8

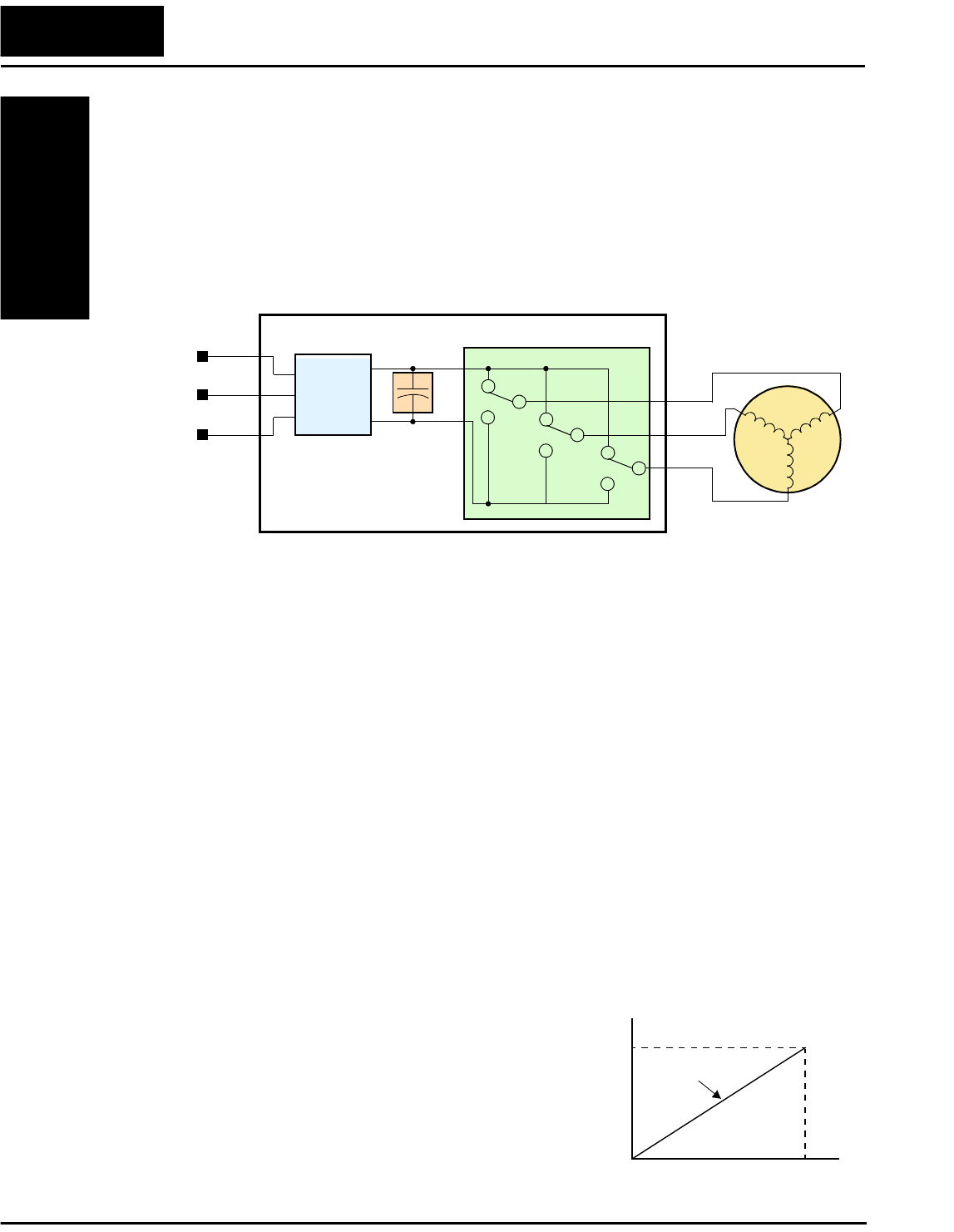

An inverter, in general, is a device that converts DC power to AC power. The popular

consumer power inverter is designed for powering an AC appliance from a car battery;

put 12VDC in, and get 115VAC 50/60 Hz out, for example. The figure below shows how

the variable-frequency drive employes an internal inverter. The drive first converts

incoming AC power to DC through a rectifier circuit, creating a high-voltage internal DC

bus. Then the inverter circuit inverts the DC back to AC again to power the motor.

However, this special inverter varies its output frequency and voltage according to the

desired motor speed.

The simplified drawing of the inverter shows three double-throw switches. Usually

implemented with six power transistors, outputs U/T1, V/T2, and W/T3 may switch

positively or negatively. Using a commutation algorithm, the microprocessor in the drive

switches the power transistors on and off at a very high speed to create the desired output

waveforms. The reactance of the motor windings helps smooth out the pulses.

Torque and Constant Volts/Hertz Operation

In working with industrial motors we often discuss the motor torque. That is simply the

rotational force the motor exerts at any given time. The goal of the inverter is to control

motor speed, but the L100 inverter only has direct control over the output frequency and

voltage. The no-load speed will be equal to the inverter output frequency minus a small

amount of slip in the motor (slip is the difference between theoretical motor speed and

actual speed). As the load increases, the slip and the delivered torque also increase . If

the inverter can create strong motor torque over most or all of the speed range, then it is

relatively easy for the system to achieve any desired speed. Speed regulation is a

measure of the accuracy speed control, given as a percent difference from a fixed value.

The L100 delivers speed regulation (no load to full load) within 3% of the (full scale)

motor nameplate speed value.

When varying the output frequency, the inverter

drive also must vary the output voltage in propor-

tion to the frequency. It does so because of the

motor’s characteristic inductive reactance. If the

drive maintains a constant volts-per-hertz ratio, the

motor will have constant torque characteristics.

Constant torque is desirable for most applications,

because it transfers power to the load consistently

across the entire speed range.

Power

Input

Inverter

L1

Motor

L2

L3

Rectifier

Variable-frequency Drive

High-voltage

DC Bus

+

+

–

U/T1

V/T2

W/T3

Converter

100%

0

V

Output frequency

f

Constant torque

Output

voltage

100%

Technologies Inc.

Toll Free: voice: 1-877-539-2542 fax: 1-800-539-2542 www.mgitech.com