L100 Inverter

Configuring

Drive Parameters

3–5

Operational Modes

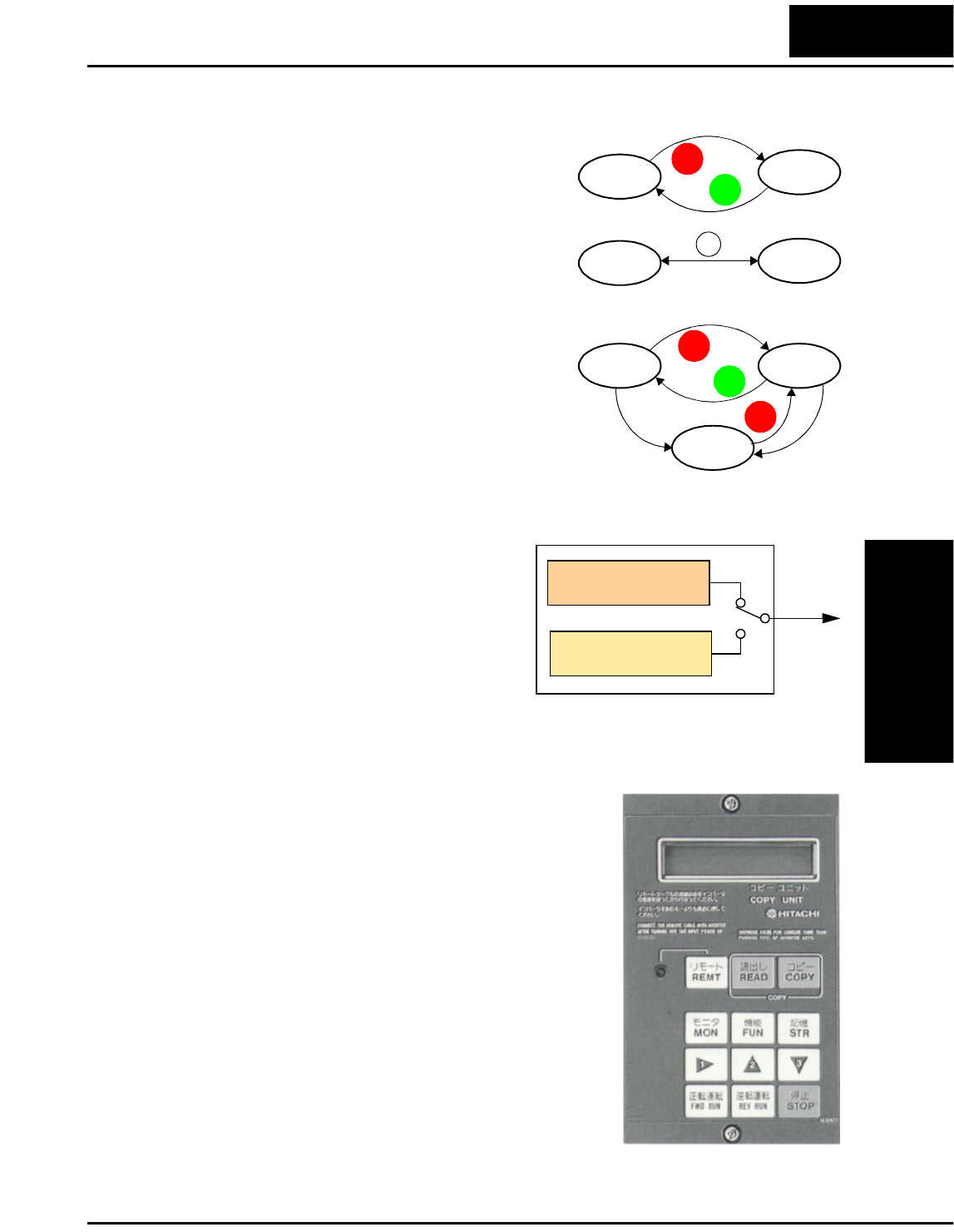

The RUN and PGM LEDs tell just part of the story;

Run Mode and Program Modes are independent

modes, not opposite modes. In the state diagram to

the right, Run alternates with Stop, and Program

Mode alternates with Monitor Mode. This is a very

important ability, for it shows that a technician can

approach a running machine and change some

parameters without shutting down the machine.

The occurrence of a fault during operation will

cause the inverter to enter the Trip Mode as shown.

An event such as an output overload will cause the

inverter to exit the Run Mode and turn off its output

to the motor. In the Trip Mode, any request to run

the motor is ignored. You must clear the error by

pressing the Stop/Reset switch. See page 6–5 for

error codes and trip history monitoring in detail.

The motor control program in the L100

inverter has two PWM sinusoidal switching

algorithms. The intent is that you select the

best algorithm for the motor characteristics in

your application. Both algorithms generate

the frequency output in a unique way. Once

configured, the algorithm is the basis for

other parameter settings as well (see page

3–13). Therefore, choose the best algorithm

early in your application design process.

Other Keypad Programming Devices

Several hand-held programming devices are available:

• Digital Operator Panel, DOP–0EA

• Digital Operator Panel and Read/Write Copy Unit

(shown at right), DRW-0EA2

• Operator Monitor, OPE-J

The keypads on these operator units are similar to the

inverter keypad (refer to the manual that comes with each

unit). These can also be panel-mounted to provide a

permanent low-cost operator interface, while keeping the

inverter secure within the cabinet. The LCD display on

the DOP units provides more detailed parameter names

and values. The DRW-0EA2 Copy Unit lets you read the

parameters from one unit and copy them to another. The

Operator Monitor can view (but not edit) parameters. See

Appendix B for DOP monitor and function tables.

Contact your local Hitachi distributor for more product information.

Run Stop

Monitor Program

RUN

STOP

STOPSTOP

STOP

RESET

FUNC.

Run Stop

RUN

STOP

STOPSTOP

STOP

RESET

Trip

Fault

STOP

STOPSTOP

STOP

RESET

Fault

Output

Variable freq. control,

constant torque

I

nver

t

er

PWM

S

w

it

c

hi

ng

Al

gor

ith

ms

Variable freq. control,

reduced torque

Technologies Inc.

Toll Free: voice: 1-877-539-2542 fax: 1-800-539-2542 www.mgitech.com