L100 Inverter

Configuring

Drive Parameters

3–17

PID Control

When enabled, the built-in PID loop calculates an ideal inverter output value to cause a

loop feedback process variable (PV) to move closer in value to the setpoint (SP). The

current frequency command serves as the SP. The PID loop calculations will read the

analog input for the process variable (you specify the current or voltage input) and calcu-

late the output. A scale factor in A75 lets you multiply the PV by a factor, converting it

into engineering units for the process. Proportional, integral, and derivative gains are all

adjustable. See page 4–27 for more information on PID loop control.

NOTE: The setting A73 for the integrator is the integrator’s time constant Ti, not the

gain. The integrator gain Ki = 1/Ti. When you set A73 = 0, the integrator is disabled.

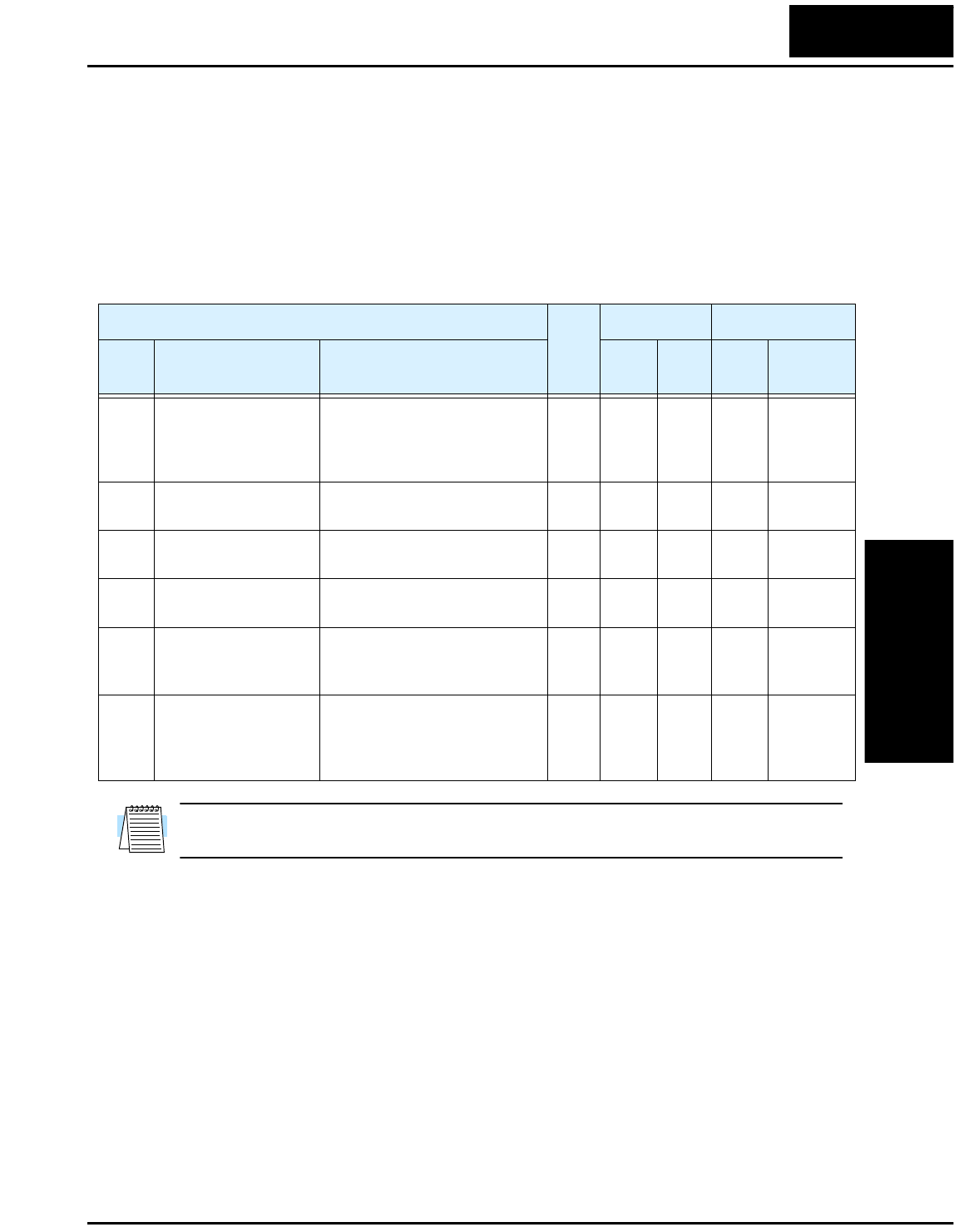

“A” Function

Run-

time

Edit

Defaults DOP,DRW,DOP+

Func.

Code

Name Description

EU/

US

Units

Func.

Code

Name

A71 PID Function Enable Enables PID function,

two option codes:

00...PID Disable

01...PID Enable

✘

00 — F-43 PID SW

A72 PID proportional gain Proportional gain has a range

of 0.2 to 5.0

✘

1.0 — F-43 PID P

A73 PID integral time

constant

Integral time constant has a

range of 0.0 to 150 seconds

✘

1.0 sec. F-43 PID I

A74 PID derivative gain Derivative gain has a range of

0.0 to 100 seconds

✘

0.0 sec. F-43 PID D

A75 PV scale conversion Process Variable (PV) scale

factor (multiplier), range of

0.01 to 99.99

✘

1.0 — F-43 PID

CONV

A76 PV source setting Selects source of Process

Variable (PV), option codes:

00...“OI” terminal (current in)

01...“O” terminal (voltage in)

✘

00 — F-43 PID INPT

Technologies Inc.

Toll Free: voice: 1-877-539-2542 fax: 1-800-539-2542 www.mgitech.com