- App. 58 -

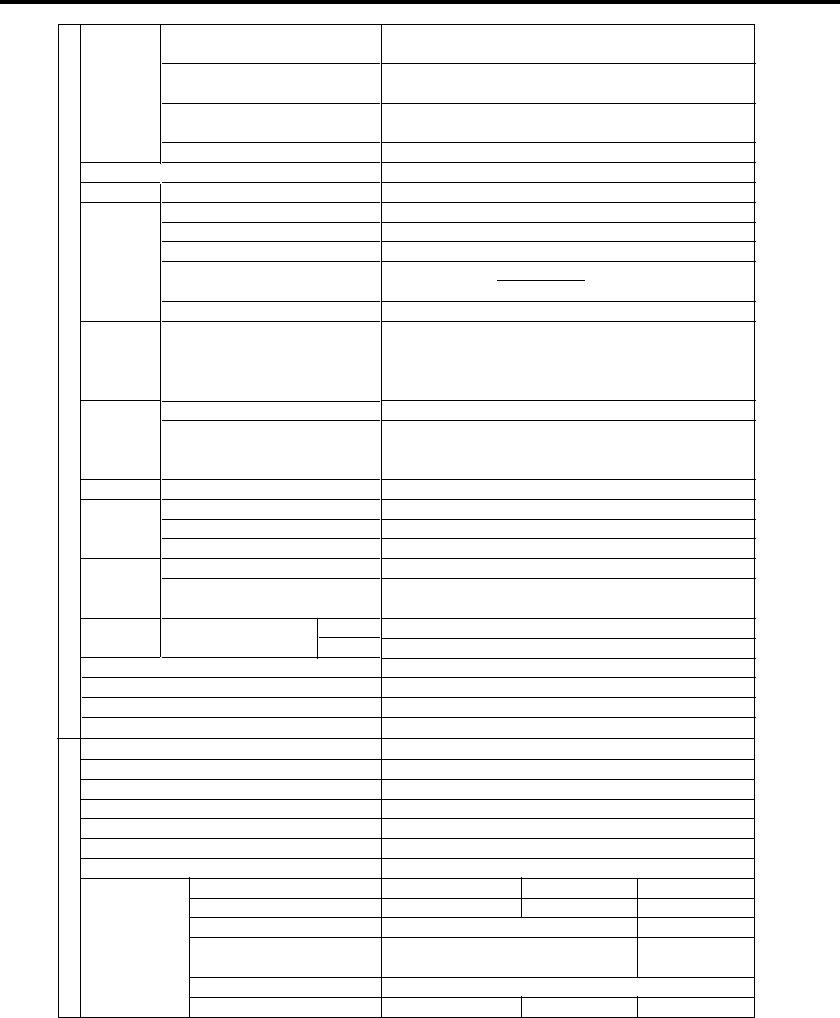

Specifications

Power

Encoder

Built-in

functions

Protective

functions

Monitor

Setting

Position Control

Velocity control

Rotary

encoder

Single-phase

100V system

Single-phase

200V system

3-phase

200V system

Permissible frequency variation

Rotary encoder

Regenerative discharge

Dynamic brake

Auto gain tuning

Electronic gear

(command pulse ratio)

Scale of feedback pulse

Stores past14 errors

including current one.

Alarms marked with *cannot

be stored.

Panel indication

Analogue output (connector pins for monitor)

Selects the items to be measured by using a param-

eter, and measuring range (output impedance of 1kΩ)

Communication

Max. input pulse frequency

Type

Command type

Internal velocity command

Acceleration/deceleration time setting

Rotary encoder phase

A/B

Feedback signal

Z phase

Single-phase, AC100

-

115V

+ 10%

50/60Hz

- 15%

Single-phase, AC200

-

230V

+ 10%

50/60Hz

- 15%

3-phase, AC200

-

230V

+ 10%

50/60Hz

- 15%

Max. ± 5%

IGBT PWM control (sine wave control)

Incremental encoder, 11 wires, 2500 P/r

External regenerative discharge resistor

Active after Main Power-Off, Servo-Off, protective function and limit switch.

Normal and Real time

Calculated as

11-wire incremental encoder: 1 to 2500 P/r

Undervoltage,Overvoltage,Overcurrent,Overload,Regenerative

discharge,Encoder error,Position error,Over speed,command pulse scaler

error,Error counter over flow,EEPROM data error,Alarms (parameter er-

ror, check code error)Overtravel inhibit input error, CPU error etc

Status LED indicator (STATUS), Error LED indicator (ALM CODE)

Velocity monitor: 6V/3000r/min (rated revolution, default)

Torque monitor: 3V/100% (rated torque, default)

Position error pulse number

RS232C

Line driver 500 kpps, Open collector 200 kpps

Line driver and open collector

Quadrature pulse command, CW/CCW pulse command and Pulse/direction command

4 speeds set-up (CW/CCW, Max.10000r/min)

0 to 10s/1000rpm, individual set-up of acceleration and decel-

eration, S-shaped acceleration/deceleration

Line driver output

Output from line driver and open collector

See "System Configuration and Wiring".

Back panel mounting

See "Outer Views and Dimensions".

See "Installation".

Amplifier

Control system

Input of control signal

Physical structure

Weight

Working environment

1-10000

x 2

0 -17

1-10000

Motor

Rated speed

Maximum speed

Holding brake

Rotary encoder

Structure (Dust proof and drip proof)

Weight

Working environment

Type

Backlash

Instantaneous max. input revolution

Efficiency

(Torque rating - Revolution rating at 20°C)

Vibration

Structure (Combined with motor)

With reduction

gear

3000r/min

30W-400W:5000r/min.750W:4500r/min

DC24V See "Holding brake built in servo motor".

Incremental encoder, 11 wires, 2500 P/r

IP65 (Except connector, shaft run-through area and reduction gear)

See "Motor outline drawing".

See "Installation".

GH (High accuracy) type GS (Standard) type GL (Popular) type

2-3˙ (Initially) 2-3˙ (Initially) 2-3˙ (Initially)

5000r/min 3600r/min

65% min. 75% min.

V-20

IP44 IP40 IP55