- 50 -

Normal mode

auto gain tuning

Real time

auto gain tuning

Manual gain tuning

Gain tuning using the rotary

switch for gain adjustment

Gain set-up: low

Gain set-up: high

+Feed forward set-up

Adjustments

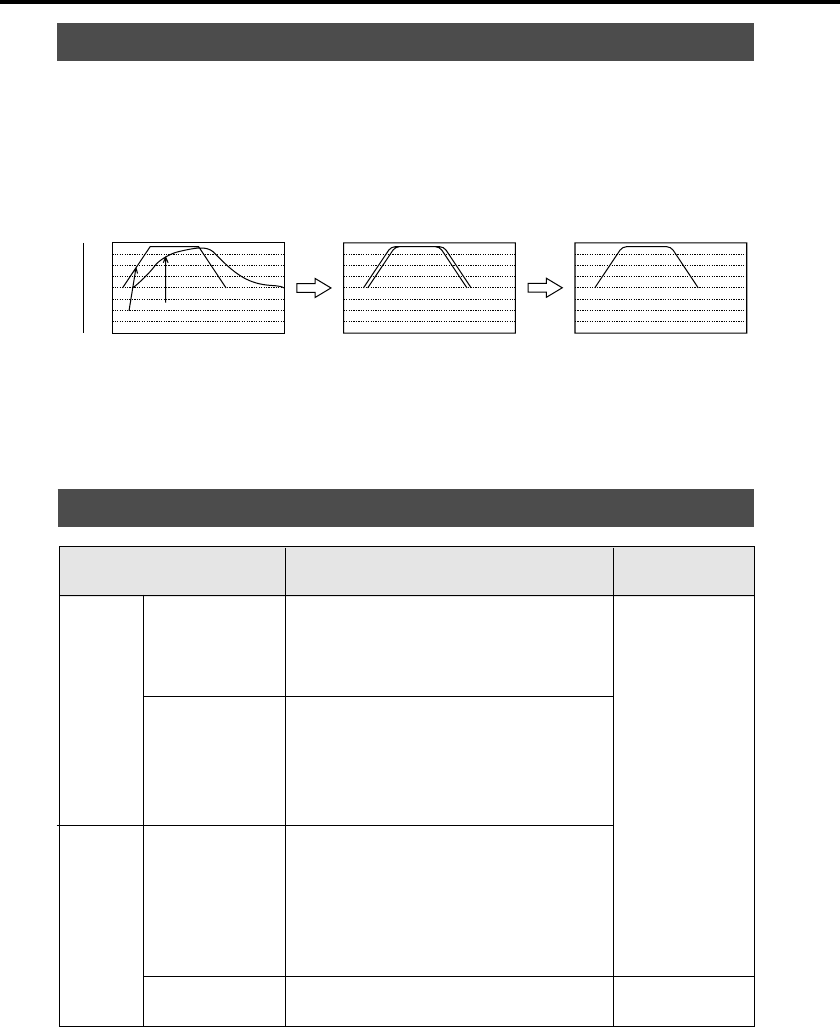

Purposes of Gain Adjustment

In case of the servo motor, the motor is required to act per any command without any

time delay, or without missing any commands. To ensure this, gain adjustment is

necessary.

<Example: ball screw>

Position loop gain

: 20

Velocity loop gain

: 100

Velocity loop integration time constant

: 50

Velocity feed forward

: 0

Inertia ratio

: 100

Position loop gain

: 100

Velocity loop gain

: 50

Velocity loop integration time constant

: 50

Velocity feed forward

: 0

Inertia ratio

: 100

Position loop gain

: 100

Velocity loop gain

: 50

Velocity loop integration time constant

: 50

Velocity feed forward

: 50

Inertia ratio

: 100

Types of Gain Adjustment

Type Description

Accelerate and decelerate the motor per the preset

(internally fixed) patterns to calculate the load inertia

from the required torque. Then automatically define

appropriate gains according to the inertia.

During an actual operation, calculate the load inertia in

real time. Then automatically define appropriate gains

according to the inertia.

The gains will be automatically adjusted against the

fluctuation of load inertia during

operation.

You can manually adjust the necessary gains to obtain

the most appropriate action by monitoring command to

the amplifier, motor speed, torque and position error as

the monitor signals (SP, IM), or using the optional

communication software, PANATERM

“

(especially with its

graphic function).

Gain adjustment is available by digital setting with

the rotary switch.

Auto-

matic

adjust-

ment

Manual

adjust-

ment

Gain set value of rotary

switch for gain adjustment

1-9

0

+2000

-2000

0

0.0 375250125 0.0 375250125 0.0 375250125

{r/min}

+2000

-2000

0

{r/min}

Actual velocity

Command Speed