FC-210/310 TROUBLESHOOTING 4 - 66 February 2002 © TOSHIBA TEC

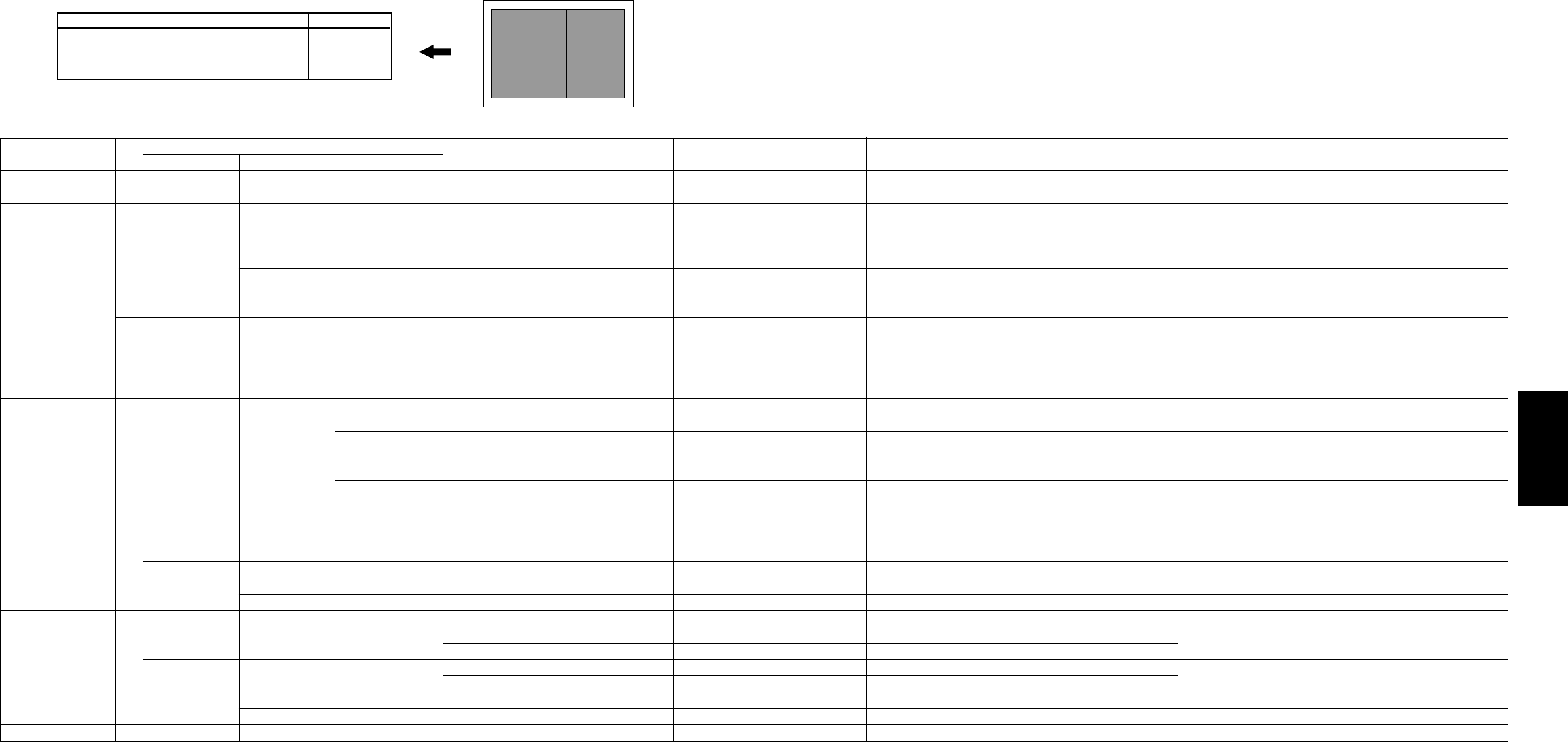

(2) Uneven pitch and jitter image

<Symptoms>

Feeding

direction

Original mode Location Phenomenon

All modes Occurs cyclically at right Uneven pitch

angles to paper feeding

direction

Section Step

Cause

Check item

Main-Classification Sub-Classification Specific-Classification

1 Output the built-in halftone and grid

patterns on A3/LD.

Paper transport 2 Paper transport Low speed Adjustment error Check the grid pattern.

syetem speed in regist-

ration section Low speed Registration roller

aging change

Low speed Registration roller Check the condition of registration

life (worn out) rubber roller surface.

High speed Adjustment error Check the grid pattern.

3 Paper transport High speed Adjustment error Check the grid pattern.

speed in fuser

unit Feed paper with the front door open

and check the paper transport between

the transfer belt and fuser unit.

Drum drive system 4 Drum Surface condition Check the halftone pattern.

Damage Check the drum surface.

Attached foreign Check the drum surface.

matter

5 Drum rotation Unstable Motor abnormal

Check drum motor operation in test mode (03).

Control circuit

Check drum motor operation in test mode (03).

abnormal

Drum motor Inadequate Adjustment error Re-check values set for drum motor

rotation speed rotaion speed.

Drum coupling Loose coupling Check the halftone pattern.

Damage

Deformation

Transfer belt system 6 Drive unit Timing belt Tension looseness Check the halftone pattern.

7 Transfer belt Deformation or Check the halftone pattern.

damage Condition of transfer belt edge.

Drive roller Slipping Stain Check the halftone pattern.

Check the condition of roller surface.

Large driving Used toner Over capacity Check the halftone pattern.

load Cleaning blade Peeling

Laser optical unit 8 Polygonal mirror Surface inclined Deformation Check the halftone pattern.

February 2002 © TOSHIBA TEC 4 - 67 FC-210/310 TROUBLESHOOTING

Criteria Measures

Perform following procedures from 2 and after.

Is there uneven pitch extending 2.5 mm to 3 mm within an area

Readjust registration motor rotation speed. * See P. 4-68.

about 130 mm wide from the leading edge of the image?

Readjust registration motor rotation speed. * See P. 4-68.

Does the roller surface lack in friction and is it slippery? Replace the registration roller.

Readjust registration motor rotation speed. * See P. 4-68.

Is there uneven pitch extending approx. 2.9 mm within an area

By fine adjustment (a few steps at a time), slacken paper

about 150 mm wide from the trailing edge of the image?

slightly, not tighten it (to a straight line in side view)

Is paper tightened? between the transfer belt and fuser unit.

Are there uneven pitches approx. 94 mm in the whole image? Replace the drum.

Is there any damage? Replace the drum.

Is there any attached foreign matter? Clean or replace the drum.

Troubleshoot the drum drive system.

Troubleshoot the drum drive system.

Is the value significantly different from the default value Reset drum motor rotation speed to 1787.

1787? (The value shifts one step each in connection

with transfer belt speed)

Re-fasten the screws.

Replace the couplings.

Replace the couplings.

Are there uneven pitches approx. 2.5 mm in the whole image? Re-fasten the screws to fix the tension arm.

Are there uneven pitches approx. 75 mm in the whole image? Replace the transfer belt (troubleshoot the transfer

Is the belt edge damaged or folded? belt).

Are there uneven pitches approx. 75 mm in the whole image? Clean it.

Is there any stain?

Are there uneven pitches approx. 75 mm in the whole image? Troubleshoot the used toner system.

Replace the cleaning blade (troubleshoot the transfer belt).

Are there uneven pitches approx. 0.3 mm in the whole image? Replace the unit.