VI - 10

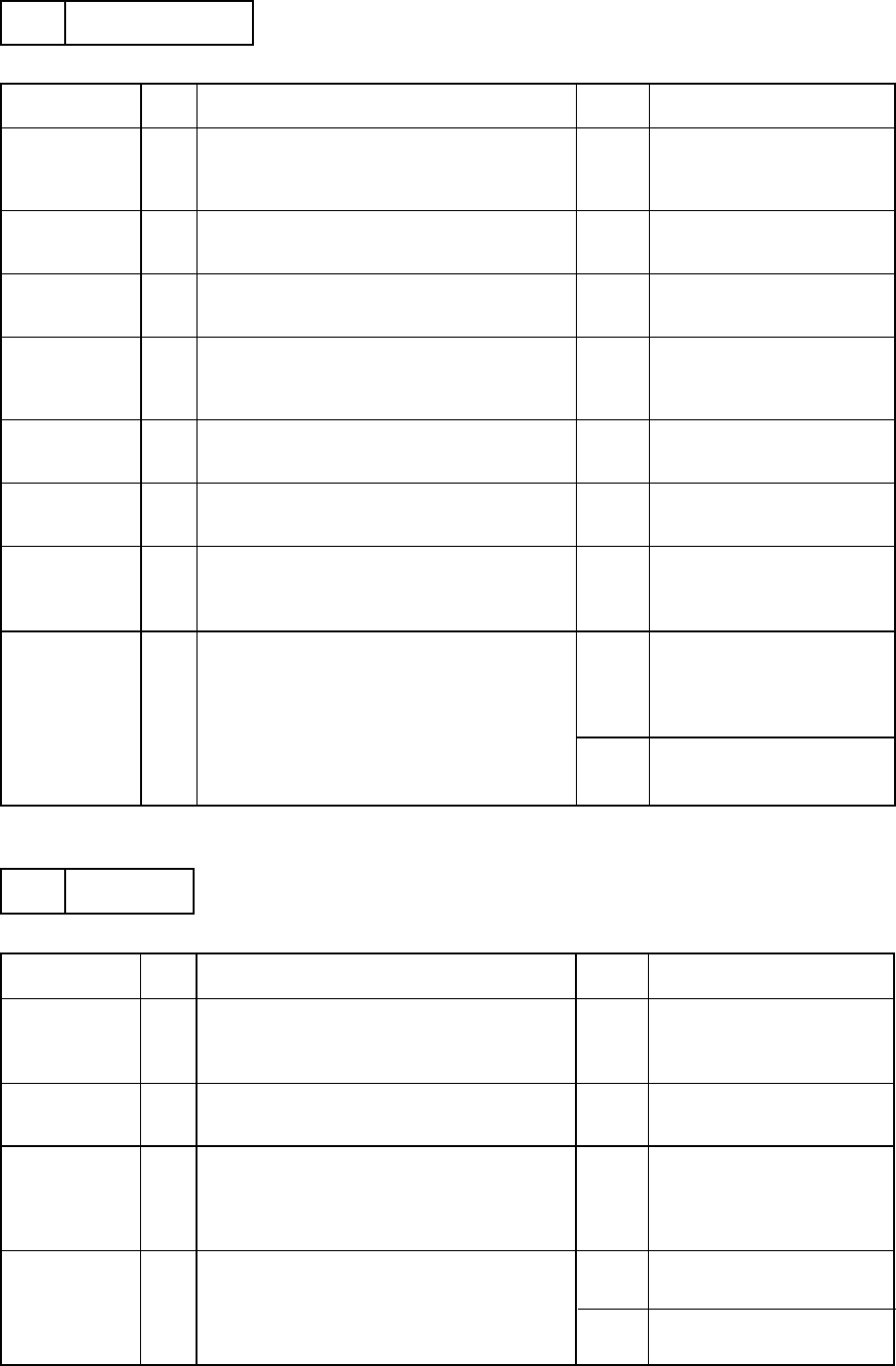

Possible cause Step Check Result Remedy

Top margin

setting error

1 Does self test printing have no problem? Yes

Check again the top margin

setting in the printing data.

Paper load in

the cassette

2 Is over-amount of paper than specified load

on the cassette?

Yes Reduce the paper load below

the specified limit.

Faulty registrationI-13

Paper failure 3 Does print quality improve when

recommended paper is used?

Yes Use recommended paper.

Paper failure 4 Is paper curled? Yes Use recommended fresh

paper without curl.

Improper Y

offset setting

5 Does print quality improve when Y offset

setting is changed?

Yes Ajust Y offset setting to an

appropriate value.

Jam remove

cover failure

6 Is the jam remove cover deformed? Yes Replace the jam remove

cover.

Failure in

regist sensor

actuator motion

7 Does the regist sensor actuator operate

smoothly?

No Reassemble the actuator

and, if the problem is not

resolved, replace the actuator.

Regist sensor

failure

8 Is the voltage at the pin 5 of the connector P3

of the main PCB 5V when no paper passes

and 0V when paper passes?

No Replace the paper feed/size-

sw PCB assy or the harness

and, if the problem remains,

replace the main PCB assy.

Paper feed

roller failure

Yes Replace the paper feed roller

assy.

Possible cause Step Check Result Remedy

Fixing unit release

spacer not

removed

1 Is the fixing unit release spacer removed? No

Remove the fixing unit

release spacer.

Paper failure 3 Is thick paper over than 36lb (135g/m

2

) used? Yes Instruct the user to use the

paper whose thickness is

less than the recommended

value.

Poor fixingI-14

Thermistor

failure

4 Is the voltage at the pin 3 of the connector

P11 of the main PCB is controlled within

1.80

±0.10V during continuous printing?

No Replace the fixing unit.

Replace the fixing unit.

Fixing unit

failure

Yes

2

MEDIA TYPE

setting

YesIs the MEDIA TYPE set to TRANSPARENCY?

Set the MEDIA TYPE to

REGULAR or THICK PAPER.