Fiber Matrix 6400 Switcher • Maintenance and Modications

7-2

Maintenance and Modifications

Removing and Installing the I/O Board or Blank Panel

W

The Fiber Matrix 6400 fiber optic I/O boards output continuous invisible

light, which may be harmful and dangerous to the eyes; use with caution.

•

Do not look into the rear panel fiber optic cable connectors or into the

fiber optic cables themselves.

•

Plug the attached dust caps into the optical transceivers when the fiber

optic cable is unplugged.

N

As factory configured, the fiber optic I/O boards are configured as either

100 percent singlemode or 100 percent multimode, but you can remove a fiber

optic transceiver module (one input and one output) of one transmission mode

and replace it with a block of the other transmission mode.

You can mix transmission mode transceiver modules on a fiber optic I/O board,

provided that you ensure that each fiber cable and connected devices are the

appropriate transmission mode for the transceiver module.

Typically, singlemode fiber has a yellow jacket and multimode cable has an

orange jacket.

N

Unlike the FOX 500 transmitters and receivers, which output an optical

stream on one connector in a block and receive a return optical stream on the

second connector in the same block, the fiber optic I/O board uses one connector

on the block as an input and the second connector on the same block as a separate

output.

N

For proper cooling and air flow, boards and/or blank panels should be installed in

all locations during normal switcher operations.

Circuit boards can be replaced for fault correction or to accommodate SDI/HD-SDI

(electric) signals. They can be added or removed to increase or decrease the I/O

configuration (size) of the Fiber Matrix.

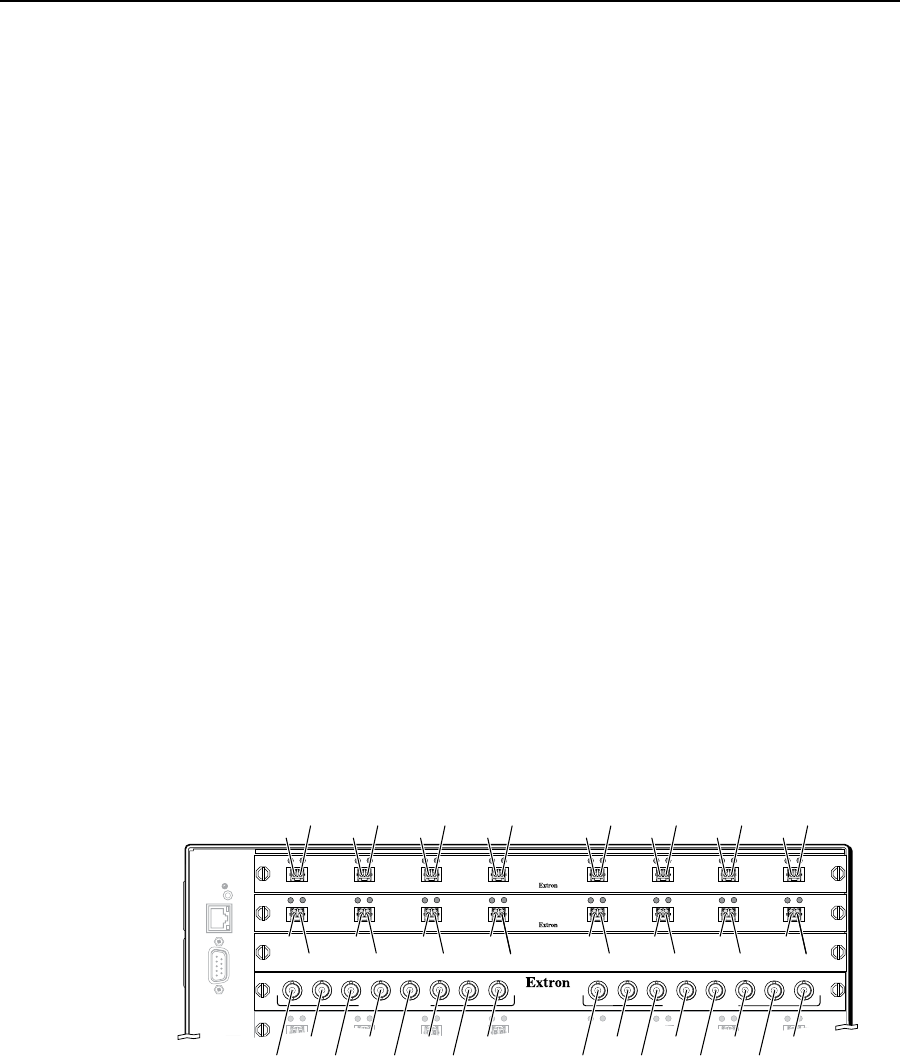

See figure 7-1. Each I/O board is identified by the input and output numbers supported

by the board position (1 - 8, 9 - 16, and so on) The transceiver modules on fiber optic

I/O boards and the BNC connectors on SDI/HD-SDI boards are identified as A through H.

RESET

RS232/RS422

REMOTE

LAN

ACT

LINK

1 - 8

9 - 16

17 - 24

25 - 3233 - 40

OUT

IN

A

OUT

IN

B

OUT

IN

C

OUT

IN

D

OUT

IN

E

OUT

IN

F

OUT

IN

G

OUT

IN

H

OUT

IN

A

OUT

IN

B

OUT

IN

C

OUT

IN

D

OUT

IN

E

OUT

IN

F

OUT

IN

G

OUT

IN

H

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

OUT

IN

MUTI-RATE SDI INPUTS

H

G

AD

E

F

C

B

MUTI-RATE SDI OUTPUTS

H

G

AD

E

F

C

B

Slot 1

O#1

I#1

Slot 2

Slot 3

No board

installed

Slot 4

O#2

I#2

O#3

I#3

O#4

I#4

O#9

I#25

I#26

I#27

I#28

I#29

I#30

I#31

I#32

O#25

O#26

O#27

O#28

O#29

O#30

O#31

O#32

I#9

O#10

I#10

O#11

I#11

O#12

I#12

O#5

I#5

O#6

I#6

O#7

I#7

O#8

I#8

O#13

I#13

O#14

I#14

O#15

I#15

O#16

I#16

Figure 7-1 — Arrangement of inputs and outputs on the I/O boards

Locations A through H correspond to the input and output numbers identified

by the board position numbers. (For example, the input and output numbers

supported by the I/O board in location 17 - 24 are as follows: A = 17, B = 18, C = 19,

D = 20, E = 21, F = 22, G = 23, and H = 24.)

On the fiber optic I/O boards, locations A through H correspond to the transceiver

modules, each of which includes an input and an output. Therefore, locations A

through H are numbered from left to right.