Chapter 1 - Installation

1-12

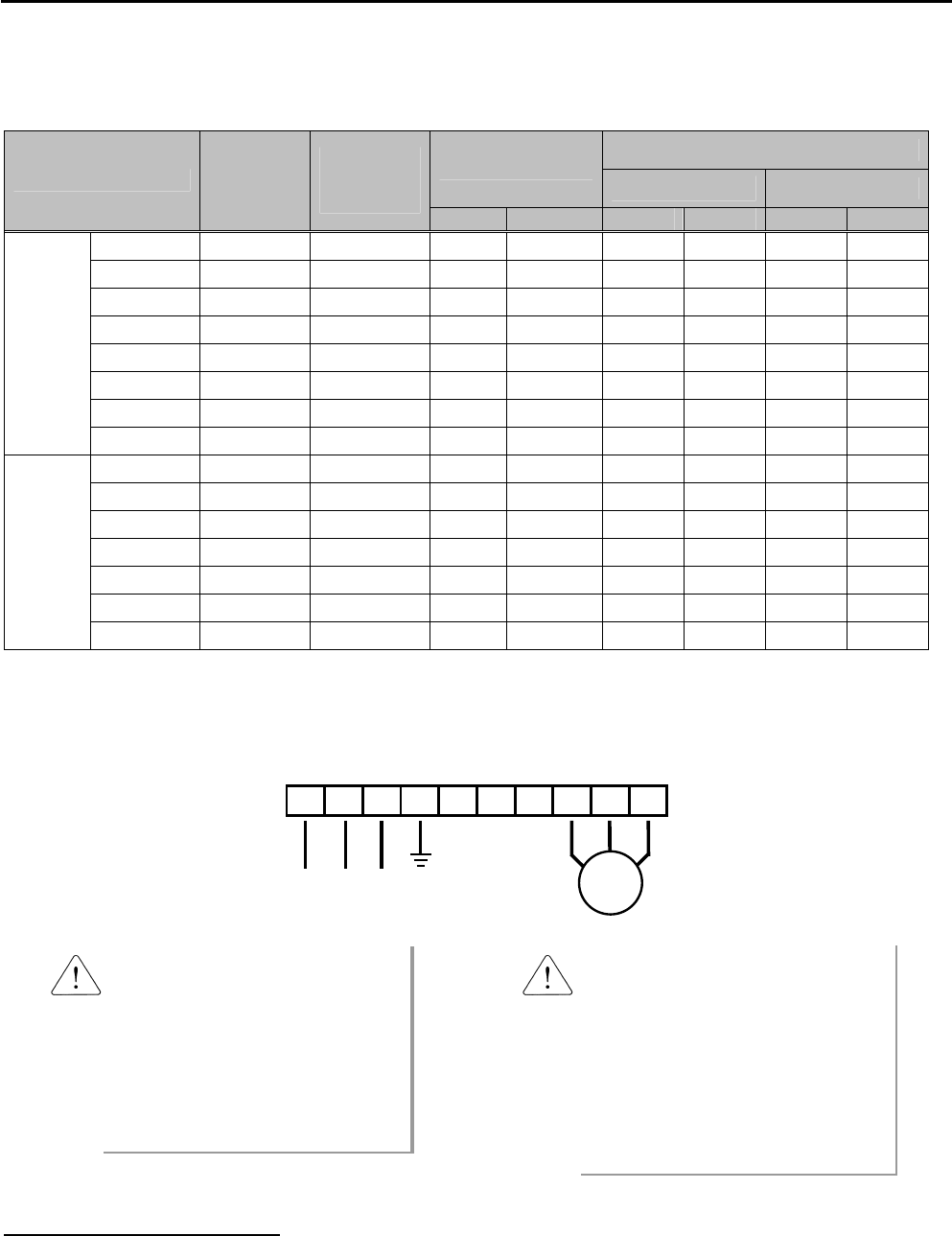

Wires and Terminal Lugs

Refer to the following table for wires, terminal lugs, and screws used to connect the inverter power input

(R, S, T) and output (U, V, W).

Wire

9

Ring Terminals

mm²

AWG

Inverter Capacity

Terminal

Screw Size

Screw

Torque

8

(Kgf·cm)/lb-in

R,S,T U,V,W R,S,T U,V,W R,S,T U,V,W

1 ~ 3 HP M3.5 15 / 10 2-4 2-4 2 2 14 14

5 HP M3.5 15 / 10 2-4 2-4 3.5 3.5 12 12

7.5 HP M4 15 / 10 5.5-5 5.5-5 5.5 5.5 10 10

10 HP M4 15 / 10 14-5 8-5 14 8 6 8

15 HP M5 26 / 18 14-5 14-5 14 14 6 6

20 HP M5 26 / 18 22-6 22-6 22 22 4 4

25 HP M6 45 / 31 38-8 38-8 30 30 2 2

200V

Class

30 HP M6 45 / 31 38-8 38-8 38 30 2 2

1 ~ 5 HP M3.5 15 / 10 2-4 2-4 2 2 14 14

7.5 HP M4 15 / 10 5.5-5 5.5-5 3.5 2 12 14

10 HP M4 15 / 10 14-5 8-5 3.5 3.5 12 12

15 HP M5 26 / 18 14-5 14-5 5.5 5.5 10 10

20 HP M5 26 / 18 22-6 22-6 14 8 6 8

25 HP M6 45 / 31 38-8 38-8 14 8 6 8

400V

Class

30 HP M6 45 / 31 38-8 38-8 22 14 4 6

Power and Motor Connection

R S T G N B1 B2 U V W

8

Apply the rated torque to terminal screws. Loose screws can cause of short circuit or malfunction. Tightening the screws too much can

damage the terminals and cause a short circuit or malfunction.

9

Use copper wires only with 600V, 75℃ ratings.

Motor

3 Phase

Power Input

Power supply must be connected

to the R, S, and T terminals.

Connecting it to the U, V, and W

terminals causes internal damages

to the inverter. Arranging the phase

sequence is not necessary.

Motor should be connected to the

U, V, and W terminals.

If the forward command (FX) is on,

the motor should rotate counter

clockwise when viewed from the load

side of the motor. If the motor rotates

in the reverse, switch the U and V

terminals.