SRPL8 Server System Product Guide 87

Determining Drive Status

Status LEDs arranged in sets of three below each of the two hot-swapping bays monitor the status

of each drive. When a yellow LED is on continuously, it is okay to hot-swap (remove and replace)

a bad drive with a good one. You DO NOT need to shut down the server to hot-swap a drive.

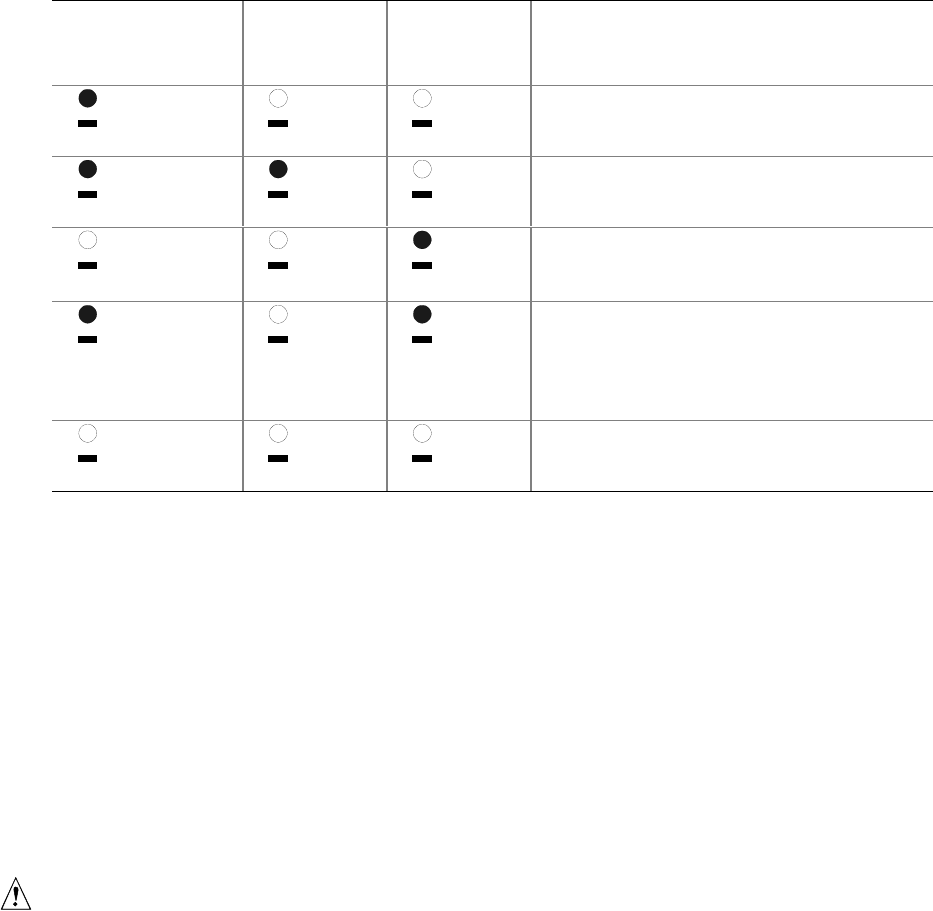

Table 13. SCSI Drive Status LED Descriptions

SCSI drive present,

power on

Green LED, A

SCSI drive

active

Green LED, B

SCSI drive

faulty*

Yellow LED, C Description and action if needed

On Off Off

Drive is present with power.

On Blinking Off

Drive is present with power and is being

accessed.

Off Off On

Drive CAN be replaced. Steady yellow fault

light indicates drive has a problem. Power to

drive is off.

On Off Slow blinking

Drive SHOULD NOT be replaced at this time.

A slowly blinking yellow fault light indicates that

a drive that has just been replaced is in

recovery mode (drive array being rebuilt).

Power to drive is on.

Off Off Off

There is no drive installed in the bay.

* The hot-swap controller is responsible for turning the yellow drive fault LED on or off according to the states specified

by commands received via SAF-TE and IMB.

1. Look at the yellow LEDs below the hot-swapping bays to determine which drive is bad.

2. Push on the drive carrier latch of the bad drive, and while grasping the handle, pull the

assembly toward you to disengage the drive from the backplane connector.

3. Before moving the drive any further, wait 30 seconds. This elapsed time allows the drive

platter to stop rotating.

4. Carefully slide the assembly out of the bay, and place it on an antistatic surface.

5. Orient the new carrier and drive assembly in front of the hot-swapping bay guide rails so that

the metal fingers of the perforated metal bracket attached to the carrier are facing up. Make

sure you correctly place the carrier into the guide rails to avoid damage.

6. While grasping only the drive carrier handle, firmly push the assembly into the bay until the

driver carrier latches.

CAUTION

Do not press on the perforated metal bracket of the carrier when you push

the assembly into the bay. Otherwise you may damage the metal fingers of

the bracket.