Appendix – Re-Assembly Procedure

8

9

0

0

Appendix

Re-Assembly Procedure for 200A /

250A drives

The followings tools are required to properly

reconnect the two cabinets:

− Socket wrench and ratchet with 150mm

(6.0”) extension

− 10mm hex socket

− #2 Phillips screwdriver, 50mm (2.0”) shaft

− #2 Phillips screwdriver, 180mm (7.0”) shaft

− Flat screwdriver, 3mm x 100mm (1/8” x 4”)

− 8mm (5/16”) Allen hex key, any length

− ½” Allen hex key, any length

− 13mm open / box end wrench

The following details the connection

procedure:

1. The U-Channels, as seen in Figure 18, are

factory bolted onto the Line Side Converter.

Verify the U-Channels are torqued between

1.81-2.26 N-m (16-20 in-lbs) on the Line

Side Enclosure

Figure 1 : Enclosure Connections

Push cabinets tightly together as seen in

Figure 9. The U-channels will lock into place

on the Motor Side Enclosure. Once the

cabinets are tightly together and placed

correctly, secure the U-channel onto the Motor

Side Enclosure using the provided four (4) M8

bolts with split lock washers. Use an open or

box end 13mm wrench to torque the four (4)

hex cap screws to 1.81-2.26 N-m (16-20 in-

lbs).

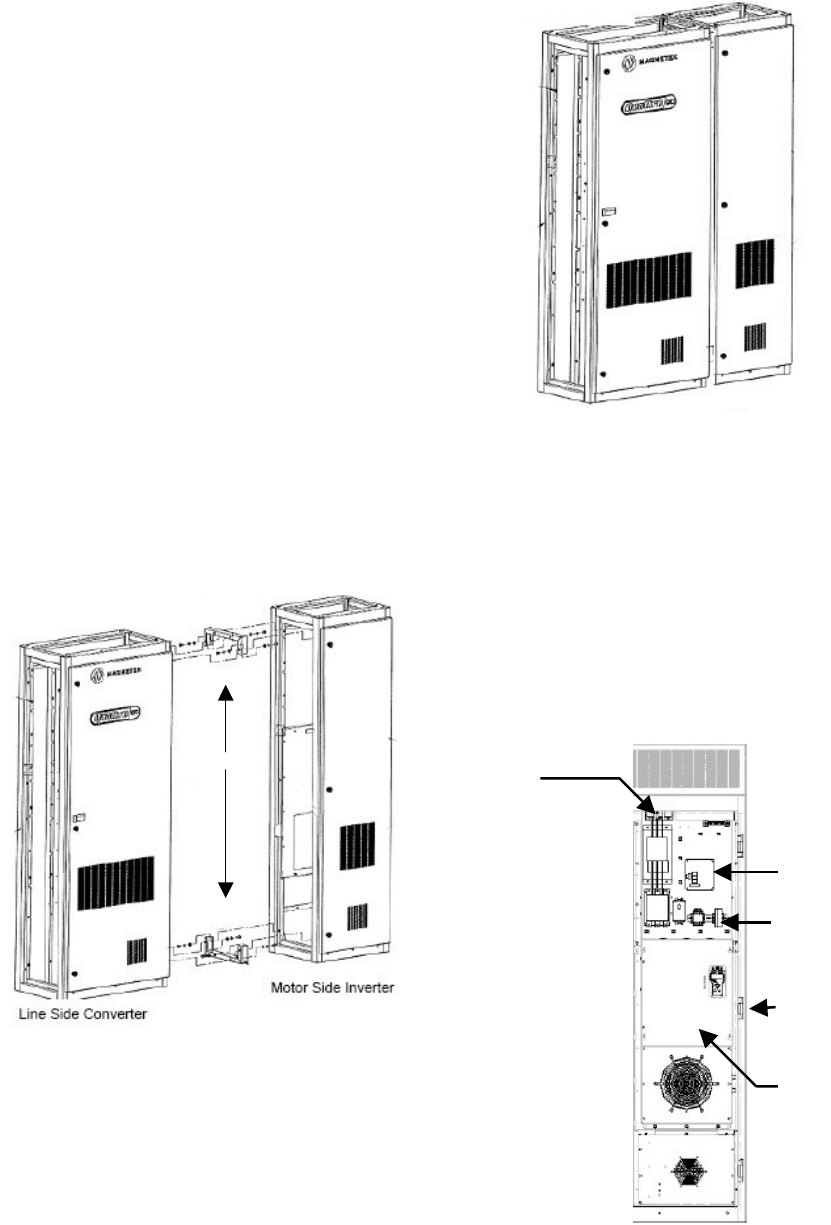

Figure 1 : Enclosures Together

2. Next, install the braided electrical ground

plate between the two cabinets. The Line

Side Converter comes pre-wired with the

ground plate pre-attached. See Figure 2

for details on where the ground plates are

located. Attach the ground plate to the

Motor Side Inverter using the provided four

(4) M5 x 9.5mm screws. Use a 8mm hex

socket with extension, or #2 Phillips

screwdriver with 50-180mm (2-7”) shaft.

Torque these connections to 4.75-5.20 N-

m (42-46 in-lbs).

U-Channels

3-Phase

Input Power

Motor Voltage

Feedback Bd (A8)

230 VAC Control

Power Input F1

& F2

Line Side

Converter

Ground Plate

Figure 2 : Line Side Module Position

98