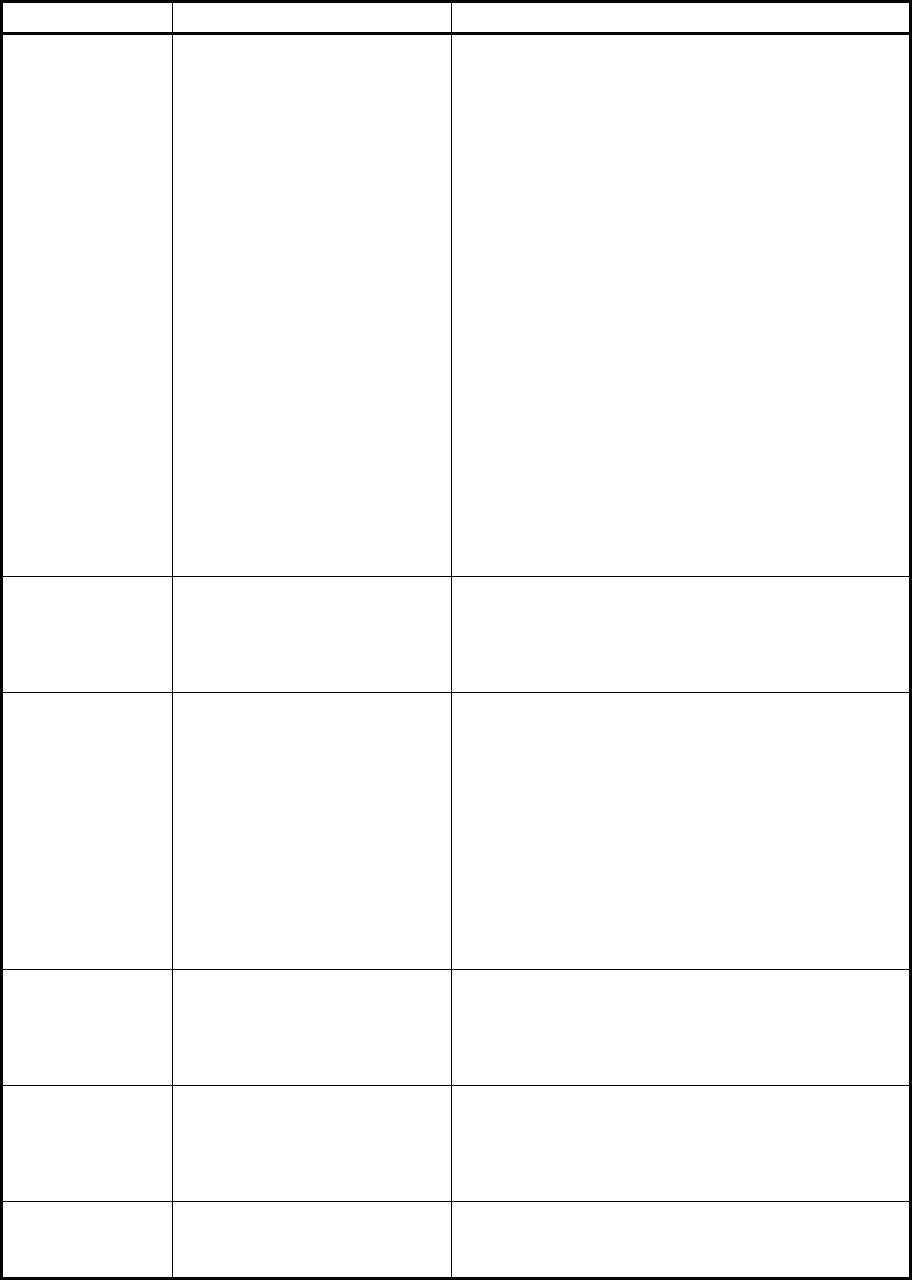

Quattro DC Troubleshooting

Name Description

Possible Causes & Corrective Action

Brk Pick Flt

The brake pick command and

the brake feedback did not

match for the time specified

with Brake Pick Time

parameter.

Check Parameter Settings

Check the correct logic input is configured for

the correct TB1 terminal and set to MECH

BRK PICK (C2)

Check BRAKE PICK SRC (C1) parameter for

the correct source of brake pick feedback

Check BRAKE PICK TIME (A1) parameter for

the correct brake hold time

Wrong assignment of Normally Closed contact

mask (C2)

Increase BRAKE PICK TIME (A1)

Verify Brake Settings

If drive is controlling brake, verify a logic output

is set to BRAKE PICK (C3)

Check for an open circuit between the brake

pick pilot relay and the logic output assigned to

brake pick control

Mechanical Brake Pick Signal Wiring

Defective Brake Pick Coil

Defective Brake Pick Auxiliary contactor used

for sensing the brake state

If nuisance fault, the fault can be disabled by BRK

PICK FLT ENA (C1) parameter.

Check Setup

This fault is logged when a

new program is loaded to the

motor side processor, and the

default data is loaded for the

parameter values.

Invalid Parameter Setup

This is an advisory fault indicating that the user

should verify the drive’s parameters

Or upload a valid parameter set using

Magnetek Explorer

Comm Fault

The drive is being operated by

serial communications and

one of the following has

occurred:

Communication time-out –

The drive did not receive a

valid run-time message in the

allowed time while running

Bad message checksum –

Drive has detected too many

consecutive bad message

checksums

Bad Serial Connection

Remove and re-seat the RS-422 serial cable

Check car controller serial driver board

Check the serial cable connected to the drive’s

RS-422 port

The Customer I/O PCB on the drive may need

to be replaced.

Comm Fault

Invalid

Checksum

(operator)

The operator received four

consecutive invalid messages

Noise or Bad Connector Connection

Remove and re-seat the operator in its cradle

If re-seating the operator did not work, the

operator or the drive’s control board may need

to be replaced

Comm Fault No

Drv Handshake

(operator)

The operator lost

communications with the

drive’s control board.

Bad Connector Connection

Remove and re-seat the operator in its cradle

If re-seating the operator did not work, the

operator or the drive’s control board may need

to be replaced

Connector Off

The power interface board has

detected a missing or loose

connector on the motor side.

Missing Connector

Verify connectors are connected

Verify connectors are properly seated

81