Quattro DC Troubleshooting

Drive Faults, Alarms, and operator messages along with possible causes and corrective actions are

listed below.

Note:

• fault - a severe failure that will stop a drive if it has been running and prevent the drive from

starting as long as it is present. All faults require some type of action by the user to clear.

• alarm - only meant for annunciation. It will NOT stop the operation of the drive or prevent the

drive from operating.

• operator message - operator communications message. It will NOT stop the operation of the

drive or prevent the drive from operating.

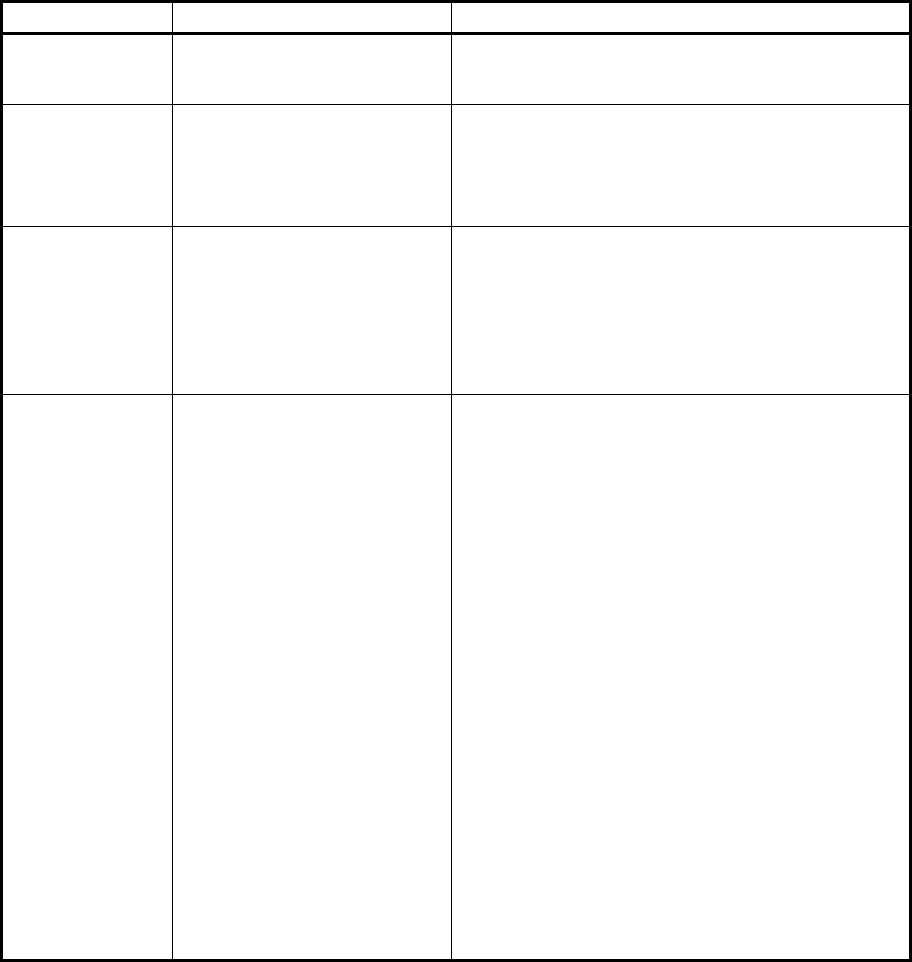

Name Description

Possible Causes & Corrective Action

A to D Fault

The Analog to Digital

conversion on the drive control

board is not working properly.

Drive Control PCB Failure

Replace Drive Control board

BAD SRL

CHKSM (alarm)

More than two messages with

bad checksums have been

received over the serial

channel.

Electronic noise interference

Verify there is no electronic noise interference

Baud rate mismatch

Baud rate mismatch is between drive and car

controller. Verify baud rate settings.

Bridge Ground

A ground fault has been

detected by the hardware on

the motor side. The current

going to A1 armature motor

lead does not match the

current returning from the

motor armature lead A2.

Check Motor Wiring

Check motor wiring and motor for insulation

breakdown or unintentional contact to other

objects

Ensure proper connection of shield drain wires

to chassis

Bad Current Sensor

Brk Hold Flt

The brake hold command and

the brake feedback did not

match for the time specified

with Brake Hold Time

parameter.

Check Parameter Settings

Check the correct logic input is configured for

the correct TB1 terminal and set to MECH

BRK HOLD (C2)

Check BRAKE HOLD SRC (C1) parameter for

the correct source of brake pick feedback

Check BRAKE HOLD TIME (A1) parameter for

the correct brake hold time

Wrong assignment of Normally Closed contact

mask (C2)

Increase BRAKE HOLD TIME (A1)

Check BRK HOLD FLT ENA (C1)

Verify Brake Settings

If drive is controlling brake, verify a logic output

is set to BRAKE HOLD (C3)

Check for an open circuit between the brake

pick pilot relay and the logic output assigned to

brake pick control

Mechanical Brake Hold Signal Wiring

Defective Brake Hold Coil

Defective Brake Hold Auxiliary contactor used

for sensing the brake state

If nuisance fault, the fault can be disabled by BRK

HOLD FLT ENA (C1) parameter.

80