Appendix – Re-Assembly Procedure

7

Auxiliary Connection

Figure 2 : Motor Contactor Connections

9. Using a flat screwdriver, 3mmx100mm

(1/8”x4”), torque the following auxiliary

terminals to 2.0 N-m (17.5 in-lbs) on the

right side of the motor contactor. See

Figure 28 for location of auxiliaries.

Wire Number

AJ9CC1-2 31

AJ9CC1-4 32

8

7

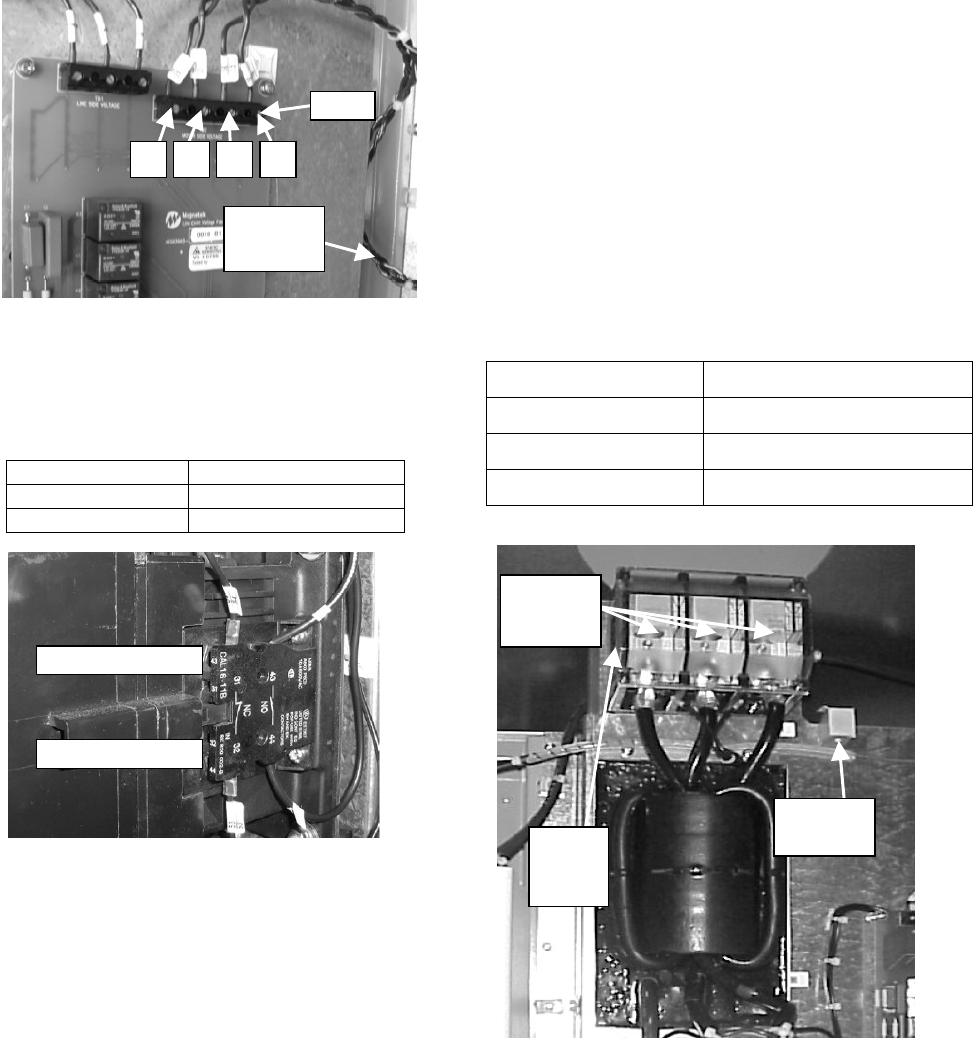

Torque the motor terminals and ground

terminals to 31.0 N-m (275 in-lbs) using a

8mm (5/16”) Allen hex key.

Tie wrap the two rubber boots to the output

terminal blocks A1 and A2 after wiring the

motor armature.

Figure 2 : Right side of Motor Contactor

10. For Motor Armature Connections, place

rubber boots over wires first, then connect

those appropriately sized wires from the

motor armature directly to the motor

contactor (ME) compression lug terminals

(1) and (3). Also connect a properly sized

frame to t ground continuity wire from the

motor he PE grounding terminal on the

Motor Side drive panel. See EMC

Compliance on page 9 .

26 25 16 19

TB2-1

To motor

contactor

11. Finally, connect the incoming 3-phase

power wires and PE building ground to the

main power terminals at the top of the Line

Side Converter enclosure. View Figure 29

for locations of terminals.

Use the following torque specs when

tighten the screws and lugs down:

Wire References Torque Specs

Power Terminals 56.6 N-m (500 in-lbs)

Plastic Cover Screws 0.23-0.28 N-m (2-2.5 in-lbs)

Ground Terminals 31.0 N-m (275 in-lbs)

9

Incoming

Power

T

e

rmin

a

l

s

Grounding

lug

Plastic

Safety

Cover

#A9JCC1-2 to 31

#A9JCC1-2 to 32

Figure 2 : Power Terminals

101