268

Parameter Settings

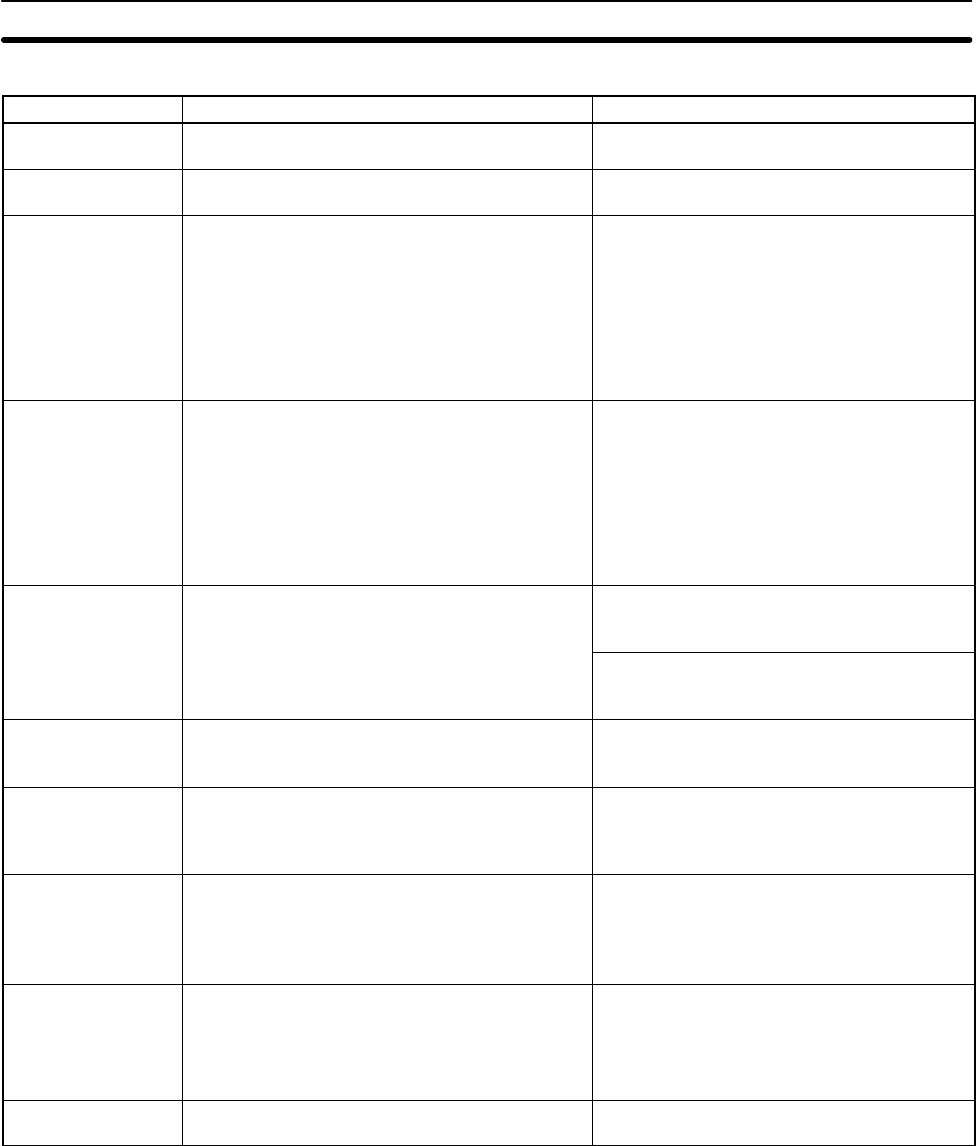

Item Contents Setting range

Set value (SV) This is the target value of the process being

controlled.

Binary data (of the same number of bits as

specified for the input range)

Proportional band This is the parameter for P control expressing the

proportional control range/total control range.

0001 to 9999 (4 digits BCD);

(0.1% to 999.9%, in units of 0.1%)

Integral time (Tik) This is a constant expressing the strength of the

integral operation. As this value increases, the

integral strength increases.

The time unit parameter determines the setting

method.

0001 to 8191 (4 digits BCD);

(9999 = No integral operation)

1× to 8191× when time unit = 0 or 1

0.1 to 819.1 s when time unit = 8

0.1 to 81.9 s when time unit = 9

Set to between 1 and 8191 times the

sampling period when a constant time is

used.

Derivative time

(Tdk)

This is a constant expressing the strength of the

derivative operation. As this value increases, the

derivative strength increases.

The time unit parameter determines the setting

method.

0001 to 8191 (4 digits BCD);

(0000 = No derivative operation)

1× to 8191× when time unit = 0 or 1

0.1 to 819.1 s when time unit = 8

0.1 to 81.9 s when time unit = 9

Set to between 1 and 8191 times the

sampling period when a constant time is

used.

Sampling period This sets the period for executing the PID

operation.

C200HX/HG/HE, CQM1-CPU4j-EV1:

0001 to 1023 (4 digits BCD);

(0.1 to 102.3 s, in units of 0.1 s)

C200HX/HG/HE only:

0001 to 9999 (4 digits BCD);

(0.01 to 99.99 s, in units of 0.01 s)

PID forward/reverse

designation

This is the parameter that determines the

direction of the proportional operation.

0: Reverse operation

1: Forward operation

(1 digit BCD)

2-PID parameter (α) This is the input filter coefficient. Normally use

0.65 (i.e., a setting of 000). The filter efficiency

decreases as the coefficient approaches 0.

000: α = 0.65

100 to 199: Rightmost two digits are α, i.e.,

0.00 to 0.99.

(3 digits BCD)

Input range This is the number of input data bits. 0: 8 bits

1: 9 bits

2: 10 bits

3: 11 bits

4: 12 bits

5: 13 bits

6: 14 bits

7: 15 bits

8: 16 bits

(1 digit BCD)

Time unit for

sampling period and

integral/derivative

times

Specifies the time unit for the sampling period

and the method for setting the integral/derivative

parameters.

0, 1, 8, or 9 (1 digit BCD)

0: Constant time, Unit: 100 ms

1: Constant time, Unit: 10 ms

8: Relative time, Unit: 100 ms

9: Relative time, Unit: 10 ms

Output range This is the number of output data bits. Same as the setting range for the input

range.

PID CONTROL Operation Execution Condition OFF

All data that has been set is retained. Then the execution condition is OFF, the

operation amount can be written to the output word (D) to achieve manual con-

trol.

Rising Edge of the Execution Condition

The work area is initialized based on the PID parameters that have been set and

the PID control operation is begin. Sudden and radical changes in the operation

output amount are not made when starting operation to avoid adverse affect on

the controlled system (bumpless operation).

When PID parameters are changed, they first become valid when the execution

condition changes from OFF to ON.

Special Math Instructions Section 5-21