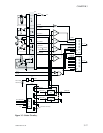

3.4.3 Status Circuitry

Figure 3-5 shows the Status circuitry. This circuitry allows the Micro Controller to monitor

all the operational status of the basic printer. On the left are Card, Ribbon panel, Flag,

Head Latch, and Head up/Down Sensors. Below these appear the Print Head

Temperature Sensing Thermistor.

Programmable resistors inside U20 set the threshold levels of U17 analog comparators a

through d and the LED intensity of the Card and Ribbon Sensors. The Micro Controller

can check the states of the analog comparators and the status of the Head Latch Sensor by

loading and then reading registers U31 and U32.

The Flag sensor produces pulses at the R FILM T signal at a rate proportional to ribbon

supply spindle rotation. Without corrective action, the rate would increase as ribbon

collects on the Take Up Spindle and increases its diameter. However, by keeping track of

the number of pulses generated for each complete ribbon panel sequence, the Micro

Controller has a basis for Ribbon Take Up Motor control. The Micro Controller reduces

motor rotation sufficiently to keep the number of pulses approximately equal for each

imaging sequence. The result serves to keep color imaging passes within the confines of

respective ribbon panels.

The Print Head raises for fast card transports and lowers for imaging. LED-Photo

transistor sensors signal related Head Up and Head Down status. Cutouts on a disk align

with the sensors to signal these events. Thedisk attaches to the shaft of the Head Up/Down

Motor.

As noted in the Motor Control descriptions, U20, and associated programable resistors,

receive control from the Micro Controller via the Serial Data line (SD1) in step with the

Serial Data Clock (SDK). The CS POT signal chip-enables U20.

3-16 980264-001 Rev.B

CHAPTER 3