5-8 DocuTech 128/155/180 HighLight Color Operator Guide

Technical information

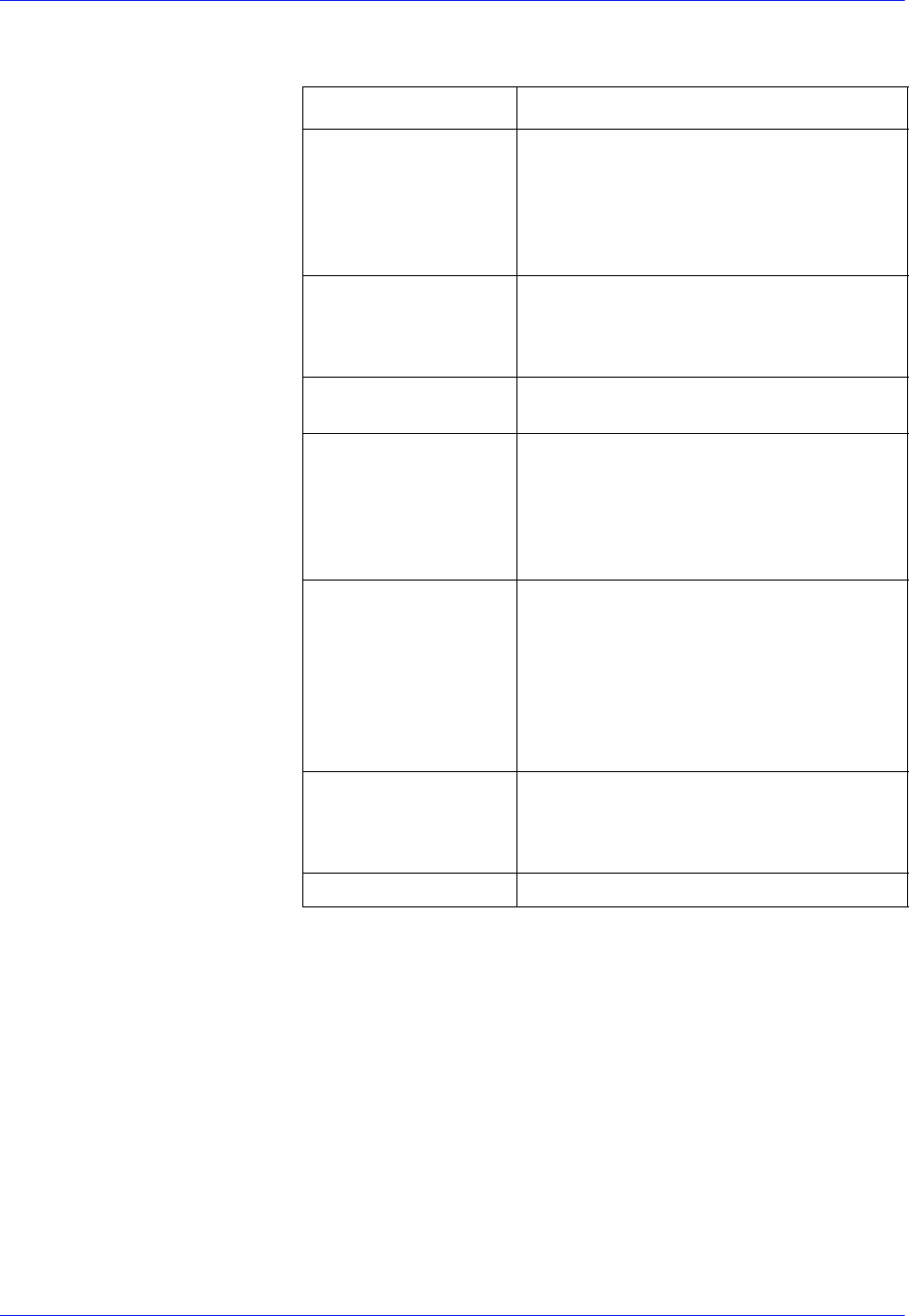

Table 5-5. Satisfaction guide for various stocks

Stock Type Instructions for use

Substance 13

(49 g/m2) paper

Use trays 3,4,or 5.

Do not run 2-sided prints.

Load the paper with seam side down into tray

3.

Optimum satisfaction can be expected with

8.5 x 11 inch (216 x 279 mm) or larger paper.

Substance 16 (60 g/

m2) paper

Load paper with seam side up into trays 1

and 2; seam side down into tray 3, 4, or 5.

Optimum satisfaction can be expected from

tray 3, 4, or 5.

Substance 20 (75 g/

m2) paper

Load the paper with seam side up into trays 1

and 2; seam side down into trays 3, 4, and 5.

Card stock

Xerox substance 65

(176 g/m2)

Substance 110 (200 g/

m2) long grain (index)

Card stock can be run from any tray.

Reduce set size if frequent paper jams or

bindexer jams occur. If collated unfinished,

another solution is to lower the value of the

bindexer capacity set in the SWITCHES

mode.

Xerox 4024, substance

20

(75 g/m2)

3 hole drilled

4 hole drilled

7 hole drilled

Load the paper into trays 1 and 2 with holes

to the right; load the paper into trays 3, 4, and

5 with holes to the left.

Use the Image Shift or Reduce/Enlarge

options to avoid printing near the holes.

Fan the paper and check the paper for loose

paper plugs before loading the paper into the

trays.

Never-tear, 3 hole

drilled

Load the paper into trays 1 and 2 with holes

to the right; load the paper into trays 3, 4, and

5 with holes to the left.

Do not bind or run 2-sided prints.

Never-tear Do not bind or run 2-sided prints.