Troubleshooting/Service

162 UDC2500 Universal Digital Controller Product Manual 4/07

7.5 Background Tests

Introduction

The UDC2500 performs ongoing background tests to verify data and memory integrity.

If there is a malfunction, a diagnostic message will be displayed (blinking) in the lower

display.

In the case of simultaneous malfunctions, the messages will appear in sequence in the

lower display. Table 7-3 lists these background tests, the reason for their failure, and

how to correct the problem.

Diagnostic messages may be suppressed (stop the blinking) by pressing the RUN/HOLD

key. The messages will still be available for viewing by pressing the LOWER

DISPLAY key.

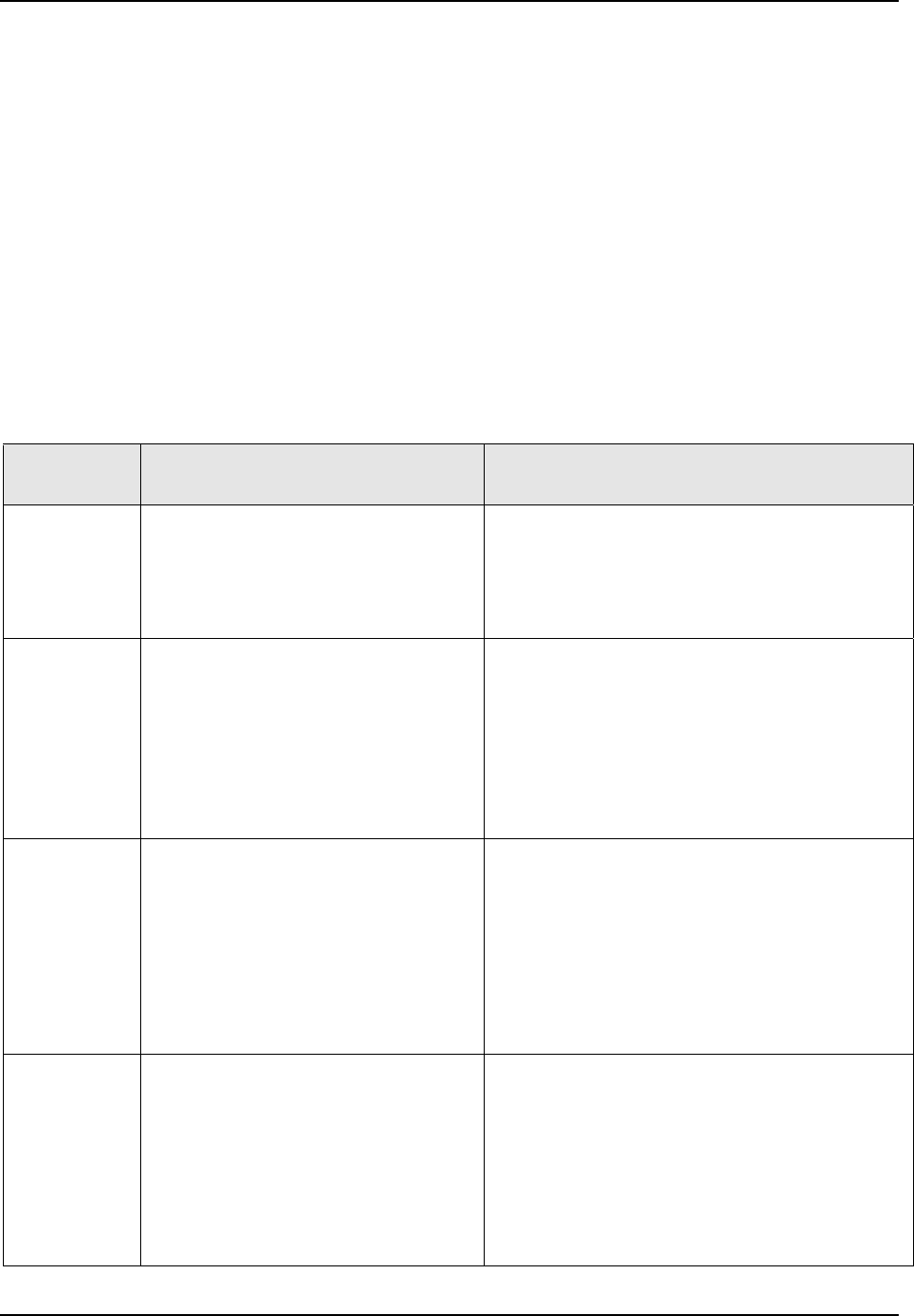

Table 7-3 Background Tests

Lower

Display

Reason for Failure How to Correct the Problem

E FAIL

Unable to write to non-volatile

memory. Anytime you change a

parameter and it is not accepted, you

will see E FAIL.

1. Check the accuracy of the parameter and re-

enter.

2. Try to change something in configuration.

3. Run through Read STATUS tests to re-write

to EEPROM.

FAILSF

This error message shows whenever

the controller goes into a failsafe

mode of operation. This will happen if:

• RAM test failed

• Configuration test failed

• Calibration test failed

• Burnout configured for none

and the input failed.

1. Run through STATUS check to determine the

reason for the failure.

2. Press the SET UP key until STATUS appears

in the lower display.

3. Press the FUNCTION key to see whether the

tests pass or fail, then run through the

STATUS codes a second time to see if the

error cleared.

IN1RNG

Input 1 out of range. The process

input is outside the range limits.

1. Make sure the range and actuation are

configured properly.

2. Check the input source.

3. Restore the factory calibration.

(See

Subsection

0.)

4. Field calibrate. See

Section 5 - Input

Calibration.

IN1_FL

Two consecutive failures of input 1

integration; i.e., cannot make analog

to digital conversion. This will happen

if:

• Upscale or Downscale

burnout is selected and the

input is open

• Input not configured correctly

for the sensor being used

1. Make sure the actuation is configured

correctly. See

Section 3 - Configuration.

2. Make sure the input is correct and that it has

not burned-out (opened).

3. Check for gross over-ranging with a

multimeter.

4. Restore factory calibration. See

Subsection

5.8