3-2

Common Operations > Loading Paper

Loading Paper

Paper can be loaded standardly in the cassette and the multi purpose tray. A paper feeder is also available as an option

(refer to Optional Equipment on page 11-2).

Before Loading Paper

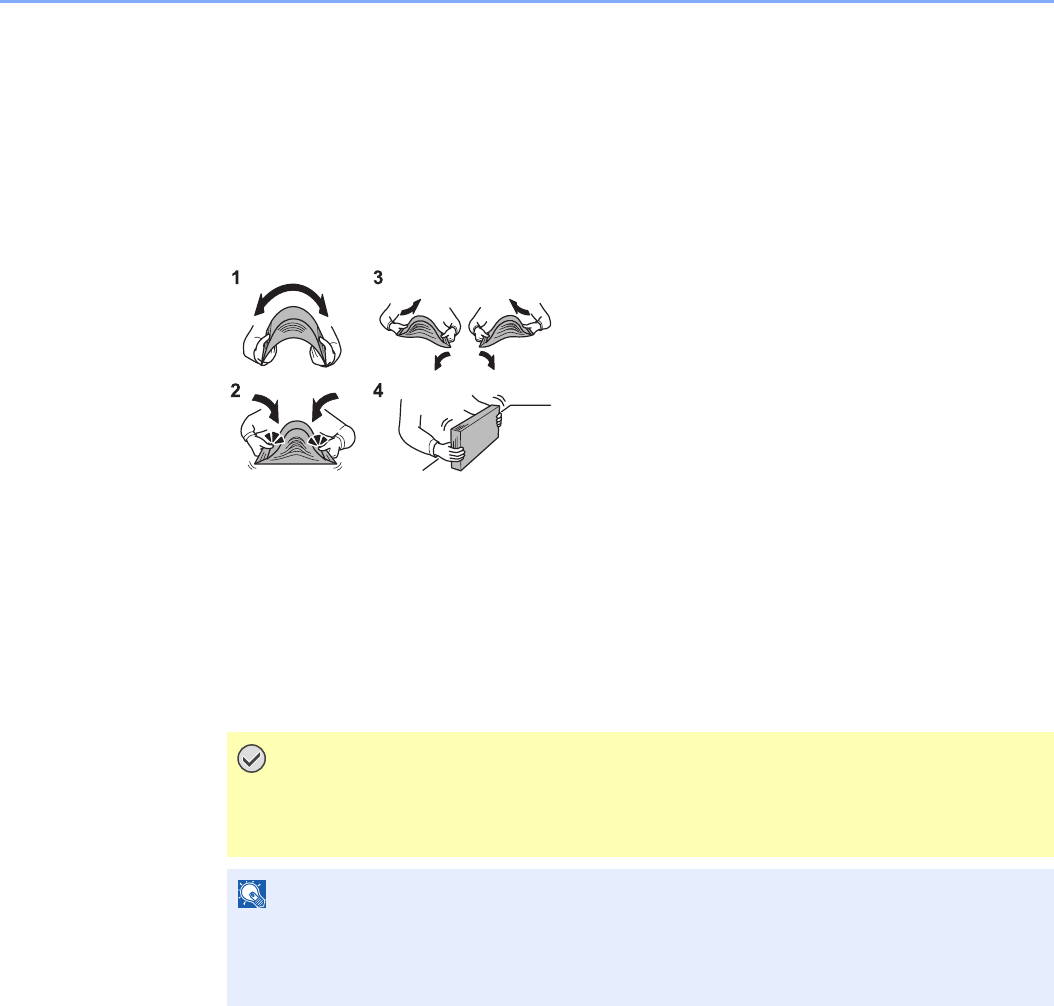

When you open a new package of paper, fan the sheets to separate them slightly prior to loading in the following steps.

1 Bend the whole set of sheets to swell them in the middle.

2 Hold the stack at both ends and stretch it while keeping the entire stack swelled.

3 Raise the right and left hands alternately to create a gap and feed air between the papers.

4 Finally, align the papers on a level, flat table.

If the paper is curled or folded, straighten it before loading. Paper that is curled or folded may

cause a jam.

Avoid exposing opened paper to high temperatures and high humidity as dampness can be a

cause of problems. Seal any remaining paper after loading in the multi purpose tray or

cassettes back in the paper storage bag.

If the machine will not be used for a prolonged period, protect all paper from humidity by

removing it from the cassettes and sealing it in the paper storage bag.

IMPORTANT

If you copy onto used paper (paper already used for copying), do not use paper that

is stapled or clipped together. This may damage the machine or cause poor image

quality.

NOTE

If printouts are curled or not neatly stapled, turn the stack in the cassette upside down.

If you use special paper such as letterhead, paper with holes or paper with pre-prints like

logo or company name, refer to Paper on page 11-10.