173

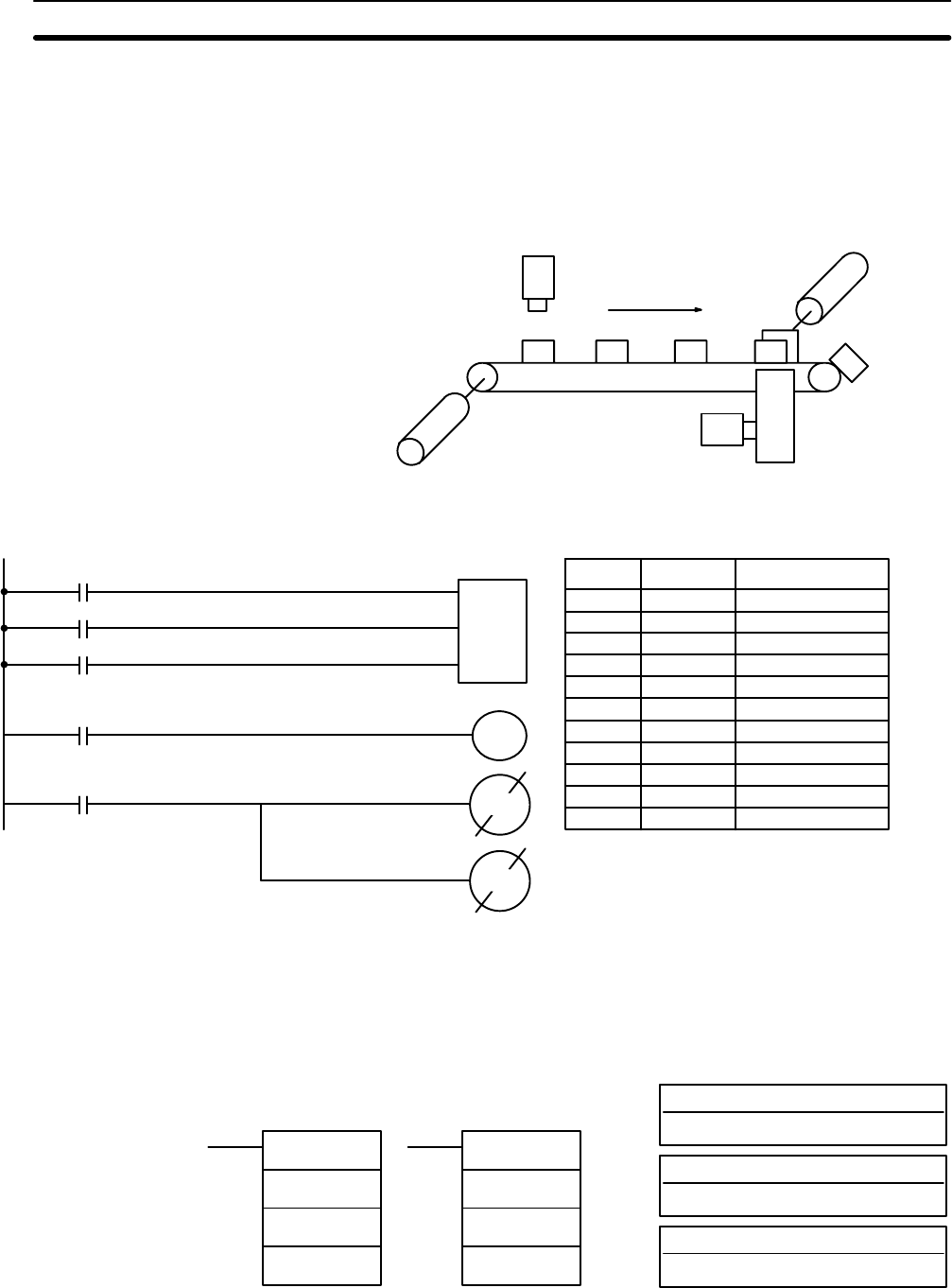

The program is set up so that a rotary encoder (00000) controls execution of

SFT(10) through a DIFU(13), the rotary encoder is set up to turn ON and OFF

each time a product passes the first sensor. Another sensor (00002) is used to

detect faulty products in the shoot so that the pusher output and HR 0003 of the

shift register can be reset as required.

Chute

(00500)

Sensor

(00001)

Rotary Encoder

(00000)

Pusher

Sensor

(00002)

I

P

SFT(10)

HR 00

HR 01

R

00001

00000

00003

00500

HR 0003

00500

HR 0003

00002

Address Instruction Operands

00000 LD 00001

00001 LD 00000

00002 LD 00003

00003 SFT(10)

HR 00

HR 01

00004 LD HR 0003

00005 OUT 00500

00006 LD 00002

00007 OUT NOT 00500

00008 OUT NOT HR 0003

5-15-2 REVERSIBLE SHIFT REGISTER – SFTR(84)

C: Control word

IR, AR, DM, HR, LR

St: Starting word

IR, SR, AR, DM, HR, LR

Ladder Symbols

Operand Data Areas

E: End word

IR, SR, AR, DM, HR LR

SFTR(84)

C

St

E

@SFTR(84)

C

St

E

Limitations St and E must be in the same data area and St must be less than or equal to E.

Data Shifting Section 5-15