Stylus Color Service Manual

Operating Principles

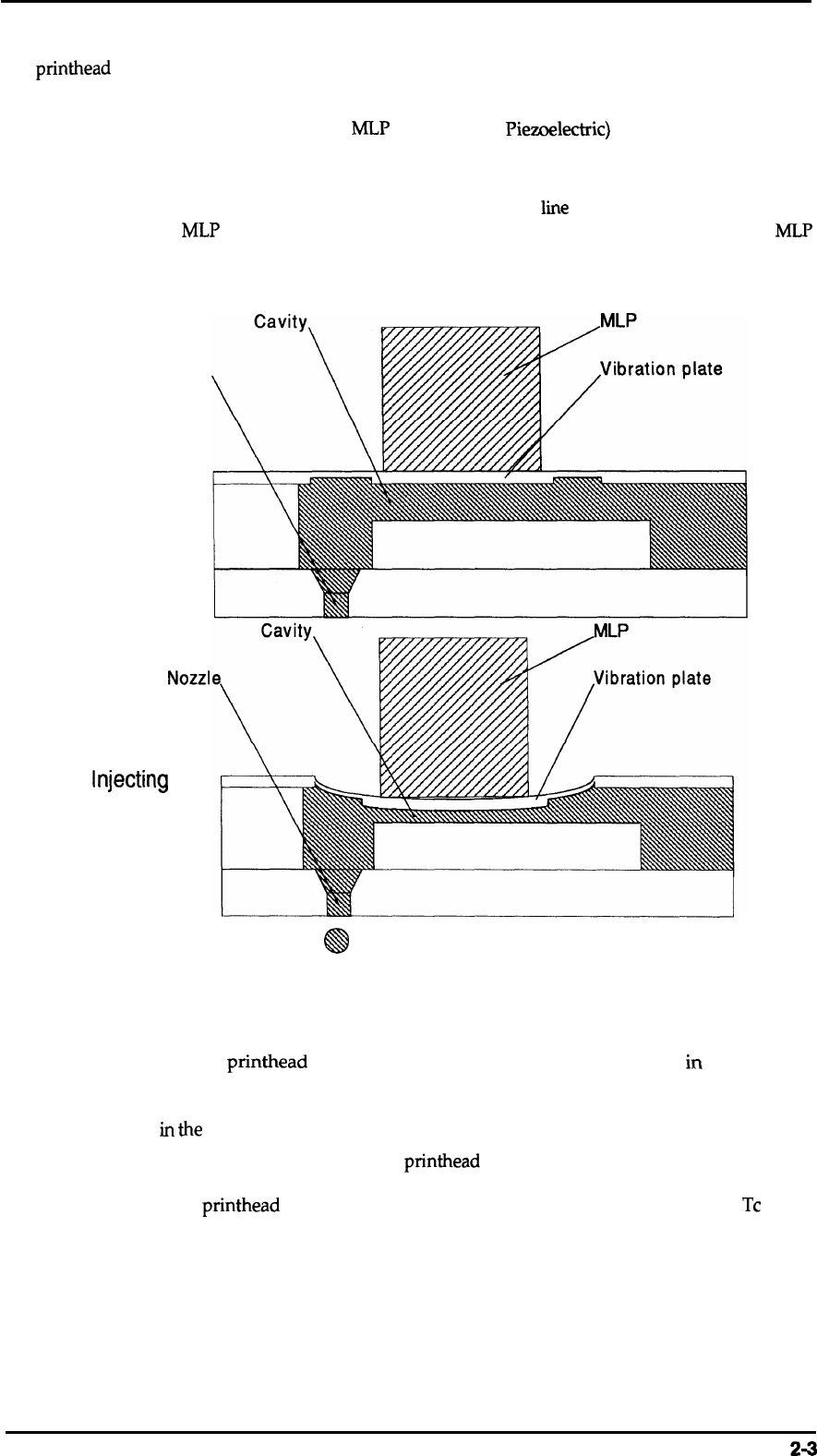

Principles of the Printing Operation

The

printhead

operates in one of two modes to inject ink from each nozzle:

■ Normal state

No electrical charge is applied to the

MLP

(Multi-Layer

Piezoelectric)

element attached to the

back of the cavity, and pressure inside the cavity is kept at a constant level.

■ Injecting state

The head data signal is applied to the specific nozzle control

line

to select the active nozzle for

printing, and the

MLP

element is gradually charged by the drive voltage. By charging the

MLP

element, the vibration plate is bent to compress the cavity. Then, ink is injected from the

nozzle.

Normal

state

Injectir

state

Nozzle

Nozzl

Ig

@

Figure 2-3. Principles of the Printing Operation

When the ink charge or

printhead

cleaning operation is performed, the ink

in

the cavity is

vacuumed out with the pump mechanism. During printing, on the other hand, the ink is

simultaneously supplied from the ink cartridge and injected from the nozzle, according to the

change of volume

in

the

cavity.

A thermistor is attached to the side of the color

printhead

drive board to monitor the temperature

because the viscosity of the ink varies, depending on the temperature. The detected temperature

level is fed back to the

printhead

drive voltage control circuit to change the time of the

Tc

pulse.

(The Tc pulse is shown in Section 2.3.2.5.)

Rev. A

2-3