EPSON Stylus Photo 750 Revision A

Maintenance Overview 93

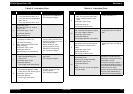

Table 6-3. Lubrication Point Table 6-4. Lubrication Point

No. Lubrication Type/Point Remarks

4

<Lubrication Amount>

• 1/4 of gear tooth for “Gear, 67.2”

• 1/3 of gear tooth for “Combination

Gear, 16,21.6”

• 1/3 of gear tooth for “Gear, 23.2”

• Rotate gears after applying

grease to evenly distribute it.

• Use a syringe to apply it.

5

<Lubrication Point>

The shaft for “Gear, 16, 40.8” on

“Frame, Left”.

<Lubrication Type> G-26

<Lubrication Amount>

Approximately 5 mm

• Use a syringe to apply it.

6

<Lubrication Point>

• Bushings for “Roller, PF”:

Left: Inside the bushing

Right: Inside the bushing(near the

pump assembly)

<Lubrication Type> G-26

<Lubrication Amount>

Approximately 3 mm diametrically

• For the right bushing, apply it

from the paper path side, and

wipe off any sticking out to the

cap assembly side.

• Rotate “Roller, PF” after

applying grease to evenly

distribute it in the bushing.

• Use a syringe to apply it.

7

<Lubrication Point>

• Both Left/Right Bushings for

“Roller, Exit”

<Lubrication Type> G-26

<Lubrication Amount>

• Evenly apply inside the bushings.

• Do not attach the grease to the

paper path.

• Use a syringe to apply it.

8

<Lubrication Point>

• Contact points between “Holder,

Pulley Driven” and “Frame, Upper”

<Lubrication Type> G-26

<Lubrication Amount>

• 2 mm long for each point.

• Apply that the holder slides

only with spring force after

applying grease.

• Use a syringe to apply it.

No. Lubrication Type/Point Remarks

9

<Lubrication Point>

• ASF; The round hole in the right

frame of ASF (to hold the roller

shaft)

<Lubrication Type> G-26

<Lubrication Amount>

Evenly apply inside the hole.

• Avoid applying grease to

“Roller, Assembly, LD”

10

<Lubrication Point>

ASF; Contact points between “Hopper”

and “Lever, Hopper, Release”.

<Lubrication Type> G-26

<Lubrication Amount>

Evenly apply lubrication to the points.

• Completely wipe off any grease

sticking out to the inner side of

ASF.

11

<Lubrication Point>

The round cutout in the left frame of

ASF (“Gear,34” is inserted to the

cutout)

<Lubrication Type> G-26

<Lubrication Amount>

Evenly apply inside the hole.

• Completely wipe off any grease

sticking out to the inner side of

ASF.

12

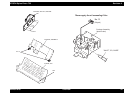

<Lubrication Point>

Oil pad in the carriage assembly.

<Lubrication Type> O-12

<Lubrication Amount>

0.7cc

Note:

This is the amount to be applied

to a new oil pad.

Lubricate the oil pad only when;

*Replacing the carriage assembly.

*Replacing the oil pad

Use a precise syringe to apply it. If

you accidentally apply too much oil

to the oil pad, throw the pad away

and take a new one again.

Leave the oil pad for a while to wait

until oil is evenly infiltrated, then

install it on the carriage assembly.