Altivar

®

58 TRX AC Drives

Assignment of Analog Inputs (AIx)

57

09/2003

© 2000–2003 Schneider Electric All Rights Reserved

ASSIGNMENT OF ANALOG INPUTS (AIX)

The following sections describe the possible assignments of the Analog

Inputs (AIx) on the drive controller and the optional I/O Extension Cards.

Speed Reference Summing

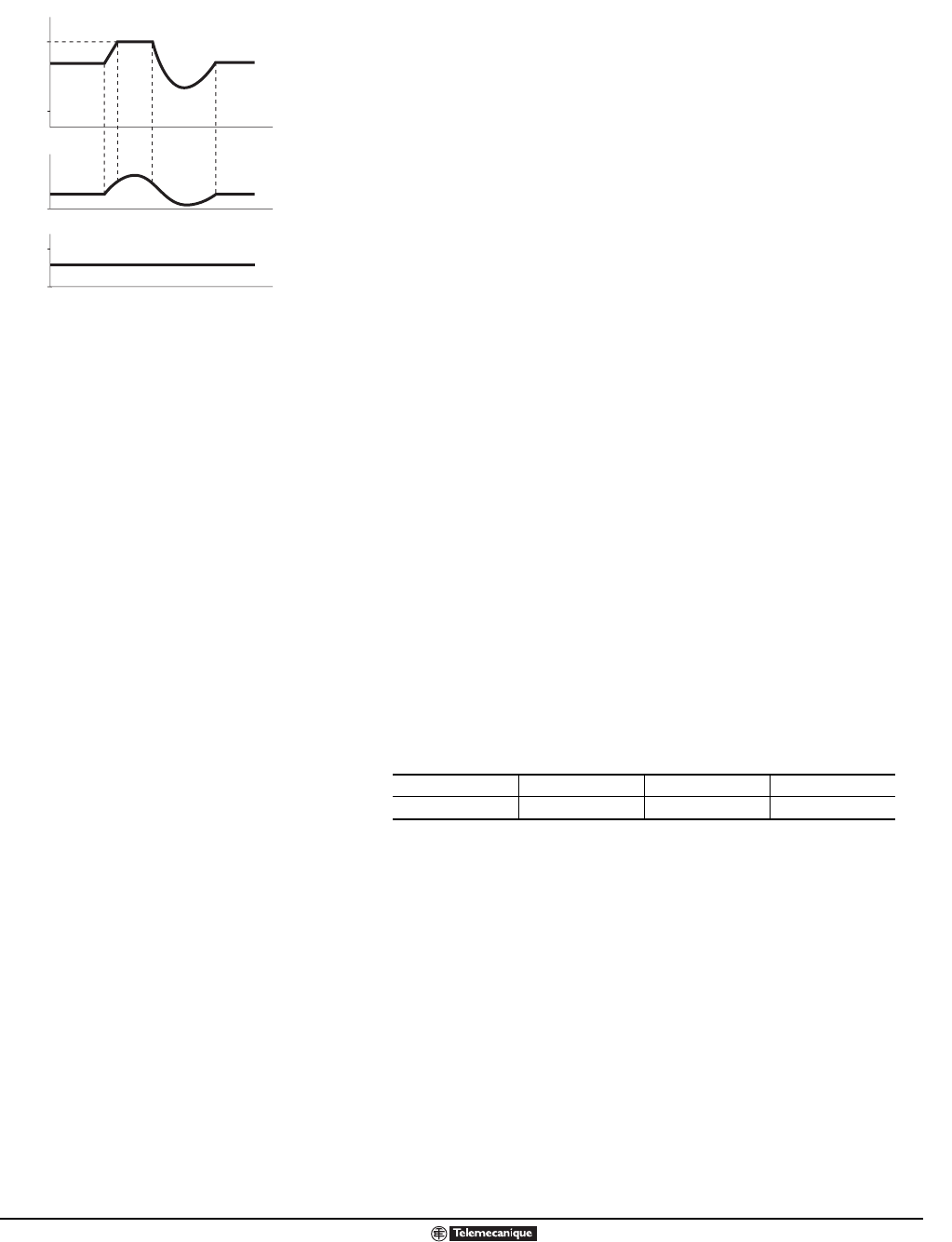

Analog input AI2 (and/or analog input AI3 with an I/O extension card) can be

assigned as a summing input for AI1 with peak limiting corresponding to the

speed HSP. This is often used for machines whose speed is controlled by a

correction signal on input AI2.

The figure to the left provides a graphical depiction of summed references.

PI Regulation

The PI Regulation function provides simple regulation of flow rate or pressure

with a setpoint input and a sensor sending a feedback signal to the drive

controller. This function is often used for pumping and fan applications. Note

that the PI Regulation function is not compatible with the Preset Speeds and

Jog functions.

The acceleration (ACC) and deceleration (dEC) ramps default to linear ramp

type even if the ramps had been configured for S ramp or U ramp.

PI regulator can be used with a logic input configured for PI Auto/Manual

mode of operation when the analog option card is used. When the PI

regulator is configured and a logic input is configured for PI Auto/Manual, the

PI regulator function is active in Auto mode and AI3 is used for speed input

in Manual mode.

Logic inputs can be used with the PI regulator to command the drive

controller to run from the analog reference, run at process maximum, or

operate with two other definable preset setpoints. The configurable setpoints

can be used to provide two different setpoints for two different processes, or

they can be used instead of using AI1 for setpoint input. For example,

providing a setpoint via the logic inputs can eliminate the need for a

potentiometer.

Four analog outputs are available to monitor various aspects of the PI

regulator function. See page 63 for more information.

PI Setpoint OPS PI Feedback OPF

PI Error OPE PI Integral Error OPI

t

t

f

(

Hz

)

H

SP

L

SP

1

0

V

t

AI2 or AI

3

AI1

S

umIn

p

uts.e

p

s

Speed Reference Summing Diagram