Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Revised March, 2012 3-71

Input Node ID and check “Timer” checkbox to enable motion status display

NodeID item: API function's argument variable “NodeID”.

Timer Checkbox: Check to display the motion status. Uncheck to disable display.

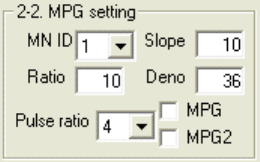

3) Enter parameter value of manual pulse control.

Figure 3.100

MN ID item: API function's argument variable “MNNodeID”.

Ratio item: Ratio between each MPG rotation and motor rotation. API function's

argument variable “ratio”.

Slope item: MPG speed slope. API function's argument variable “slope“.

Deno item: Denominator for motor rotations per MPG revolution. API function's

argument variable denominator”.

Pulse ratio item: Ratio of pulses per MPG revolution. API function's argument

variable “pulse_ratio”.

4) Set Servo Motor Power ON/OFF(servo on/servo off)

Click on the “SVON” button to execute the following procedure:

rt = _DMC_01_ipo_set_svon(gDMCCardNo, NodeID, SlotID , ON_OFF);

// ON_OFF: 0 – Servo Power OFF; 1 – Servo Power ON

5) If you wish to execute “Manual Motion Control 1”, you must check the “MPG”

checkbox and execute the following procedure:

rt = _DMC_01_get_rm_input_value(CardNo, NodeID, SlotID, Port, &Value);

// Retrieve the value for bit 0 to bit 15 of the remote I/O module's input port

rt = _DMC_01_set_rm_mpg_axes_enable(CardNo, MasterNodeID, MasterSlotID,

NodeID, SlotID, enable, pulser_ratio, ratio, slope); // Manual motion control 1

If you wish to execute “Manual Motion Control 2”, you must check the “MPG2”

checkbox and execute the following procedure:

rt = _DMC_01_set_rm_mpg_axes_enable2(CardNo, MasterNodeID, MasterSlotID,

NodeID, SlotID, enable, pulser_ratio, ratio, slope, denominator);

// Manual motion control 2. ratio is the numerator for motor rotations per revolution;

denominator is the denominator for motor rotations per revolution; These two

parameters can be used to customize the MPG outputs.