Chapter 4 Parameters|

4-52 Revision June 2008, 04EE, SW--PW V1.11/CTL V2.11

Settings 0 First Master Frequency Command Only

1 First Master Frequency + Second Master Frequency

2 First Master Frequency - Second Master Frequency

02.02 Stop Method

Factory Setting: 0

Settings 0 STOP: ramp to stop E.F.: coast to stop

1 STOP: coast to stop E.F.: coast to stop

2 STOP: ramp to stop E.F.: ramp to stop

3 STOP: coast to stop E.F.: ramp to stop

When the 2

nd

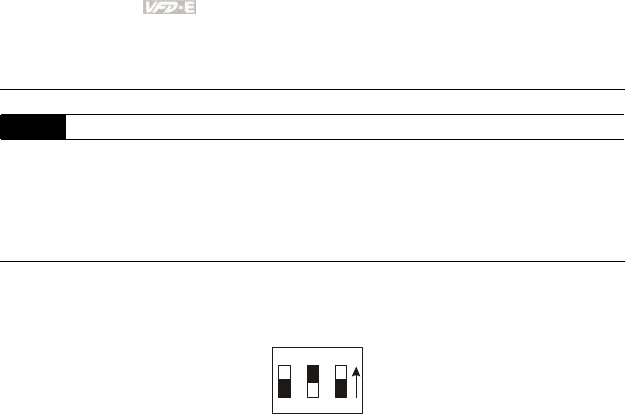

switch on the upper-right corner is set to be ON as shown in the following

diagram, the motor stop method (Pr.02.02) will force setting to 1. This setting (Pr.02.02) can’t

be changed till the 2nd switch is set to be OFF.

ON

123

The parameter determines how the motor is stopped when the AC motor drive receives a valid

stop command or detects External Fault.

Ramp: the AC motor drive decelerates to Minimum Output Frequency (Pr.01.05)

according to the deceleration time and then stops.

Coast: the AC motor drive stops the output instantly upon command, and the motor

free runs until it comes to a complete standstill.

The motor stop method is usually determined by the characteristics of the motor load and

how frequently it is stopped.

(1) It is recommended to use “ramp to stop” for safety of personnel or to prevent

material from being wasted in applications where the motor has to stop after the

drive is stopped. The deceleration time has to be set accordingly.

(2) If motor free running is allowed or the load inertia is large, it is recommended to

select “coast to stop”. For example: blowers, punching machines, centrifuges

and pumps.