14 - 1

LEAK TESTING

ETC00303(1) BINOS E e (2.0) 11/00

Rosemount Analytical

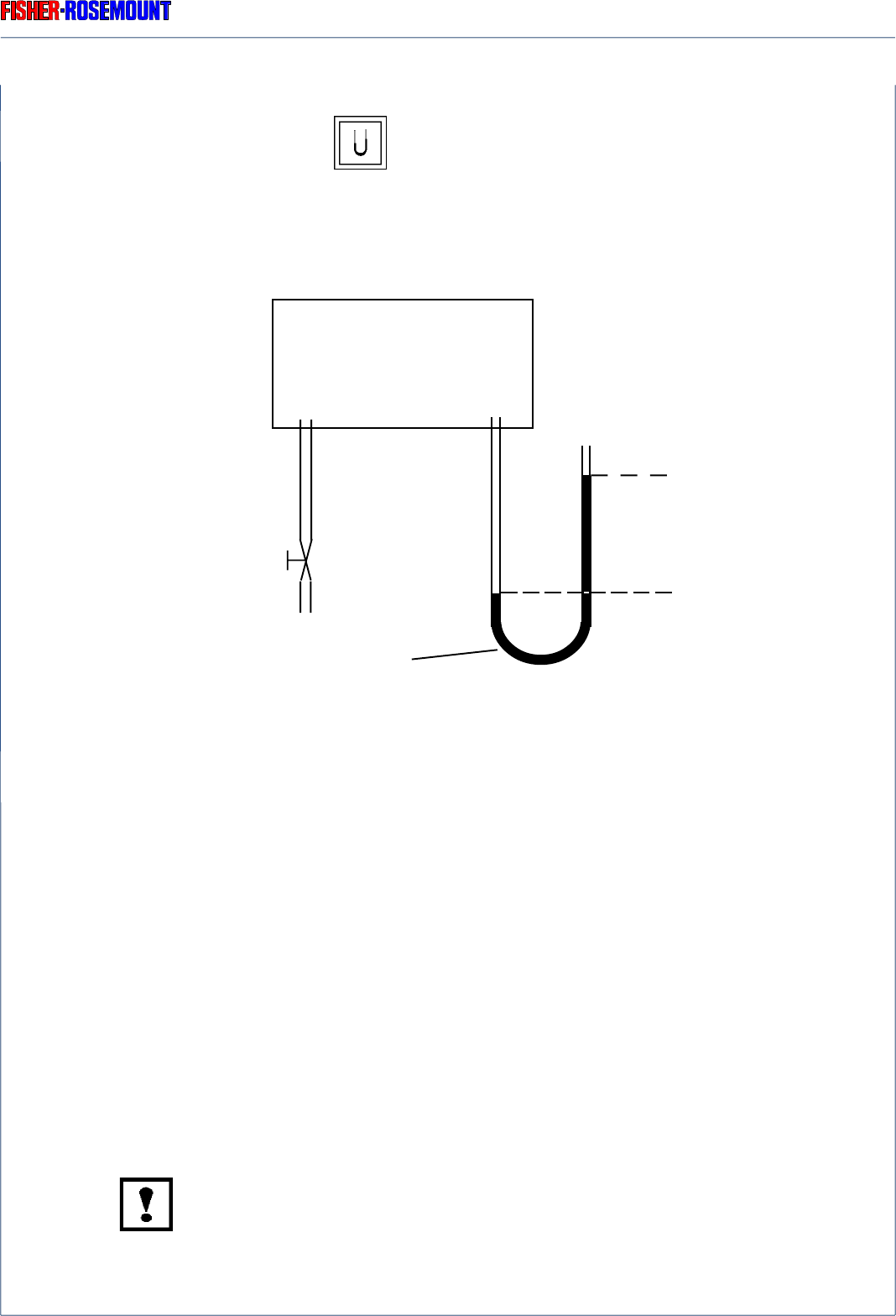

Fig. 14-1: Leak Testing with an U - Tube - Manometer

❍ Install a water - filled U - tube manometer at the sample gas outlet;

❍ Install a shut-off valve at the sample gas inlet.

Admit air into the instrument at the shut-off valve until the entire analyzer is subjected

to an overpressure of 50 hPa (approximately 500 mm water column; see Fig. 14-1).

Close the shut-off valve and verify that following a brief period required for pressure equilibrium,

that the height of the water column does not drop over a period of about 5 minutes.

Any external devices, such as sample gas cooling hardware, dust filters etc., should be

checked in the course of leak testing.

Overpressure max. 500 hPa !

For differential measurement the leakage check must be performed for

measurement side and reference side separately !

For analyzers with parallel gas paths the leakage check must be performed for

each gas path separately !

14. Leak Testing

Testing for gas leakage should be performed at bimonthly intervals and always immediately

after any repair or replacement of gas - line components is performed. The test procedure is

as follows:

Analyzer /

Analyzer Module

Overpressure

approx. 50 hPa

Valve

Water