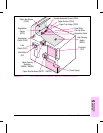

Multi-Bin Mailbox Operation

All communication and control of the Multi-Bin Mailbox (and the

2000-Sheet Input Unit) is through the External Paper Handling (EPH) PCA

mounted on the Formatter Assembly. These instructions are sent to the

Multi-Bin Mailbox controller PCA located at the bottom of the frame. The

main components of the Multi-Bin Mailbox and their functions are listed in

Table 5-5. Power is provided to the Multi-bin Mailbox (MBM) by an

external 24Vdc power supply that plugs into the MBM controller PCA. The

Multi-Bin Mailbox (MBM) provides four output modes:

• 125-sheet face-up bin. This is the top bin of the unit. It replaces the

printer’s Face-Up bin.

• Mailbox Mode. This mode uses the remaining eight (five in the Mailbox

with Stapler) bins. Up to eight (five in the Mailbox with Stapler) users

can be assigned their own bin.

• Job Separator Mode. Different print jobs are placed in separate bins

starting from the top (Bin 1) to the bottom (Bin 8 in the MBM and Bin 5

in the Mailbox with Stapler).

• Virtual Stacker Mode. Printed sheets are stacked in the bins from the

bottom (Bin 8 in the MBM and Bin 5 in the Mailbox with Stapler) to the

top (Bin 1) regardless of print job. The first sheet is sent to the bottom

bin until it is full; the next sheet is sent to the next upward bin, etc.

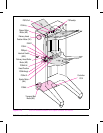

In Mailbox and Job Separator Modes, when power is applied to the unit, the

delivery head first moves to the bottom of the frame, and then upward to

the top “home” position. It then checks that all the bins are installed, and if

any are full with PSBinFull/Head Position. After these checks, the delivery

head returns to the top or “home” position. In Virtual Stacker Mode, after

counting the bins, the delivery head moves to the lowest numbered empty

bin (using PSBinEmpty).

The printer delivers the paper to the MBM at its speed of 107 mm per

second. The paper sheets are moved through the MBM transport and

delivery systems approximately five times faster (500 mm per second) than

the printer delivers them in order to maintain print speeds. The sheet

delivery speed for Bins 1 through 8 (Bins 1 thorugh 5 in the Mailbox with

Stapler) is reduced to 200 mm per second just prior to release to prevent

uneven stacking. Transport Belt speed is monitored by PSBelt.

When paper is to be delivered, the delivery head moves to the bin indicated

by the commands from the EPH PCA. The Eject roller is inserted into the

bin and starts rotating. The MBM then signals the printer that it is ready

to receive paper.

The printer feeds the paper sheet through the face-up delivery slot to the

MBM input guide. Paper arrival is sensed by PSEntry. If the paper is

designated for the face-up bin, the MBM feeds it through the flipper

assembly and releases it into the top bin at 350 mm per second. If the sheet

is designated for one of the face-down bins (bins 1 through 8, or 5 in the

Mailbox with Stapler), it is fed through the flipper assembly until the

5

Functional

Overview

Functional Overview 5-31