71

[Setting]

Setting

Standard default : < >

Servo

PrNo.

Setup

range

UnitTitle Function/Content

6C

*

0 to 3

for

A, B-frame

<3>

for

C to F-frame

<0>

–External

regenerative

resistor set up

With this parameter, you can select either to use the built-in regenerative

resistor of the driver, or to separate this built-in regenerative resistor and

externally install the regenerative resistor (between RB1 and RB2 of

Connector CN X2 in case of A to D-frame, between P and B2 of terminal

block in case of E, F-frame).

<Remarks>

Install an external protection such as thermal fuse when you use the

external regenerative resistor.

Otherwise, the regenerative resistor might be heated up abnormally and

result in burnout, regardless of validation or invalidation of regenerative

over-road protection.

<Caution>

When you use the built-in regenerative resistor, never to set up other

value than 0. Don't touch the external regenerative resistor.

External regenerative resistor gets very hot, and might cause burning.

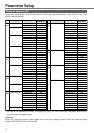

Setup value

<0>

(C, D, E and

F-frame)

1

2

<3>

(A, B-frame)

Built-in resistor

External resistor

External resistor

No resistor

Regenerative processing circuit will be

activated and regenerative resistor overload

protection will be triggered according to the

built-in resistor (approx. 1% duty).

The driver trips due to regenerative overload

protection (Err18), when regenerative

processing circuit is activated and its active

ratio exceeds 10%,

Regenerative processing circuit is activated,

but no regenerative over-load protection is

triggered.

Both regenerative processing circuit and

regenerative protection are not activated, and

built-in capacitor handles all regenerative

power.

Regenerative resistor

to be used

Regenerative processing and

regenerative resistor overload

6D

*

35 to 1000

<35>

2msMain power-off

detection time

You can set up the time to detect the shutoff while the main power is kept

shut off continuously.

The main power off detection is invalid when you set up this to 1000.

6E 0 to 500

<0>

%Emergency stop

torque set up

You can set up the torque limit in case of emergency stop as below.

• During deceleration with the setup of 8 or 9 of SV.Pr67 (Error response

at main power-off)

• During deceleration with the setup of 8 or 9 of SV.Pr69 (Sequence at

Servo-OFF)

Normal torque limit is used by setting this to 0.

<Caution>

The stop is not due to the emergency stop input (EMG-STP: CN X5 Pin 2).

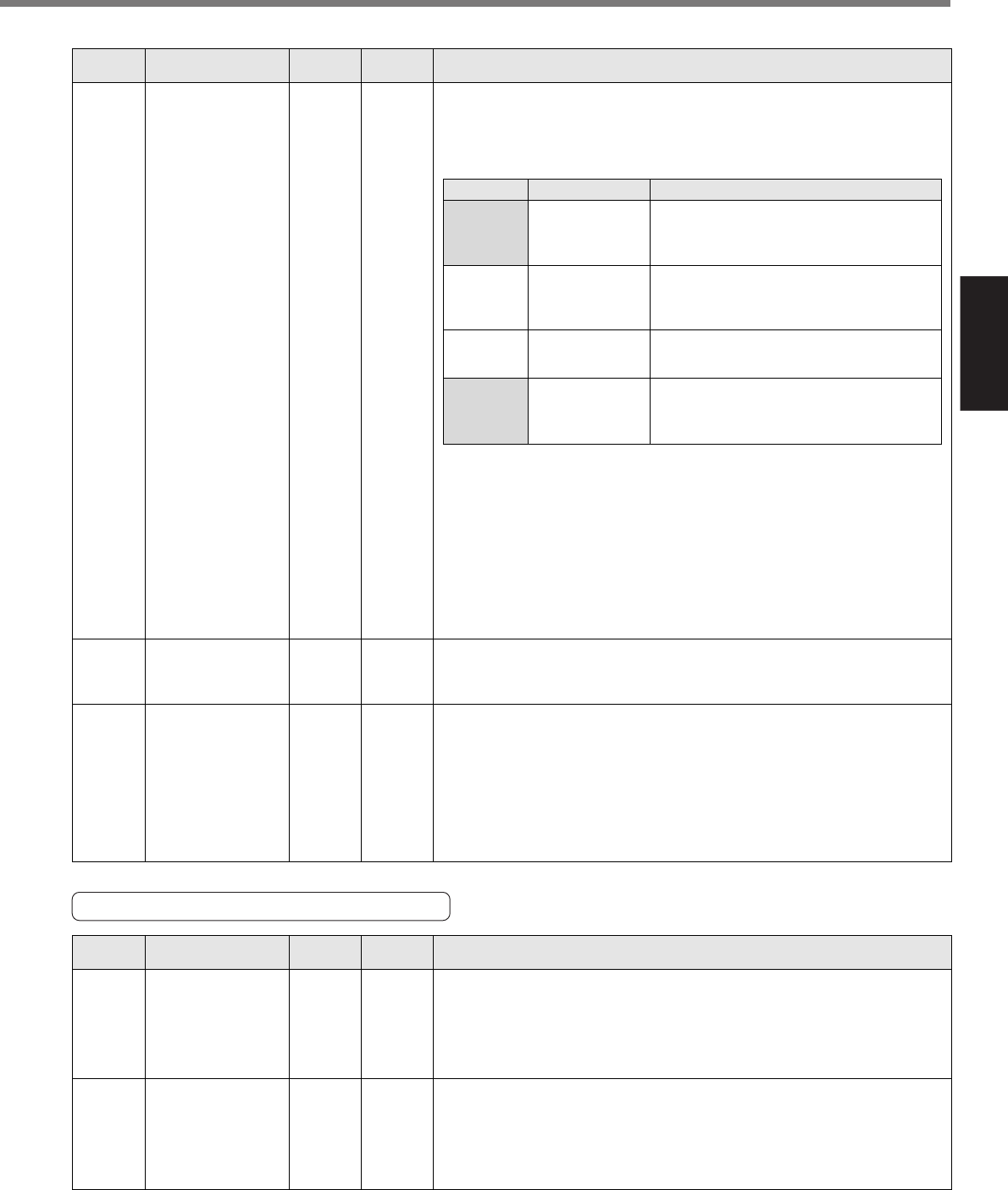

Standard default : < >

Servo

PrNo.

Setup

range

UnitTitle Function/Content

70

0 to 32767

<25000>

256 x

pulse

Position deviation

error level

• You can set up the excess range of position deviation.

• Set up with the encoder pulse counts at the position control and with the

external scale pulse counts at the full-closed control.

• Err24 (Position deviation excess protection) becomes invalid when you

set up this to 0.

72 0 to 500

<0>

%Overload level • You can set up the over-load level. The overload level becomes 115 [%]

by setting up this to 0.

• Use this with 0 setup in normal operation. Set up other value only when

you need to lower the over-load level.

•

The setup value of this parameter is limited by 115[%] of the motor rating.

Parameters for Protective function