TOSHIBA

3 - 3

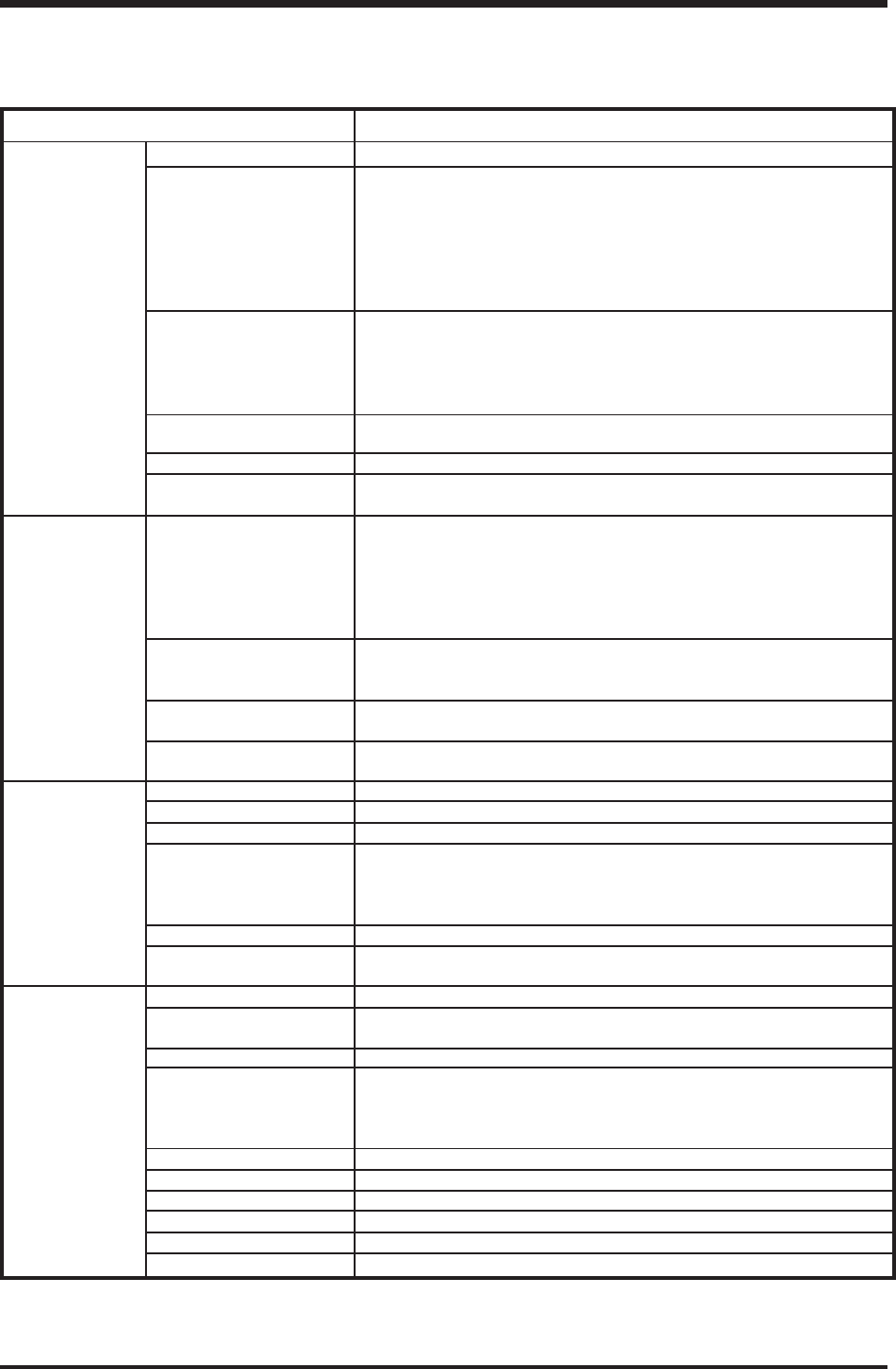

ITEM STANDARD SPECIFICATIONS

Standard Specifications (cont'd)

2

Display Interface 2-line backlit display LCD 20 characters per line

Fault display Overcurrent, overvoltage, heatsink overheat, load-side short-circuit,

load-side ground fault, inverter overload, stator overcurrent during

start-up, load-side overcurrent during start-up, EEPROM error, RAM

error, ROM error, communication error, (dynamic braking unit

overcurrent/overload), (emergency stop), (undervoltage), (low

current), (overtorque), (open output phase), (motor overload). Items

in parenthesis can be selected or deselected.

Monitor functions Terminal input/output status, forward/reverse, frequency setting

value, output frequency, output current, output voltage, input power,

output power, torque current, cumulative run time, past faults,

excitation current, DBR overload ratio, inverter overload ratio, motor

overload ratio, PID feedback value, DC voltage.

Selectable units display Can scale frequency display.

Selection of display of current in amps or %, voltage in V or %.

LED charge indicator Indicates that the main circuit capacitors are charged

LED local/remote Mounted in LOCAL/REMOTE key. Indicates local (keypad) or

indicator remote (terminal) control

Inverter/Motor Protective functions Soft-stall, current limit, overcurrent, overvoltage, short-circuit at load,

load-side ground fault, undervoltage, momentary power failure,

regeneration power ride-through, electronic thermal overload

protection, main circuit overcurrent at start-up, load-side overcurrent

during start-up, DBR resistor overcurrent/overload, heatsink over

heat, emergency stop, open output phase.

Electronic thermal Drive's motor overload protection for motor can be adjusted for motor

characteristics rated amperage. Motor overload has adjustable speed sensitivity.

Soft stall on/off. Motor 150% time programmable.

Reset Fault reset via keypad, remote contact closure, or programming drive

retry. Cycling power also resets fault (fault display can be maintained)

Regeneration power Some H3 ratings can use regen energy from motor to maintain

ride-through control operation during brown-outs.

Output signals Fault detection signal NC/NO form C contact (250VDC, 2A)

Low speed/reach signals Dry contacts (250VDC, 2A)

Upper limit/lower limit Dry contacts (250VDC, 2A)

Programmable meter Pre-compensation reference frequency, post-compensation output

output signals frequency, frequency setting value, output current, DC voltage,

output voltage, torque current, excitation current, PID feedback value,

motor/inverter/DBR overload ratio, input/output power.

Pulse-train frequency Open collector output (max. 24 Vdc, 50mA)

Communication functions RS232C equipped as standard ( connector: modular 6P), RS485,

TOSLINE-F10, TOSLINE-F20, RIO, DN, and MB+ are options.

Enclosure Type NEMA Type 1

Cooling method Forced air cooling . Fan can be automatically stopped when not

necessary for extended fan life.

Color Sherwin Williams Precision Tan #F63H12

Service environment Indoor. Consult factory for elevations above 1000m (requires derate).

For example, at 2000m, derate drive FLA by 11%.

Must not be exposed to direct sunlight, corrosive and/or explosive

gases or mists, fibers and dusts.

Ambient temperature From -10°C to 40°C (14°F to 104°F).

Relative humidity 20 to 95% maximum (non-condensating)

Vibration 5.9 m/s (0.5G) maximum (10 to 55Hz)

Climatic class 3K3

Polution degree 2

IP rating 2X