TOSHIBA

8 - 34

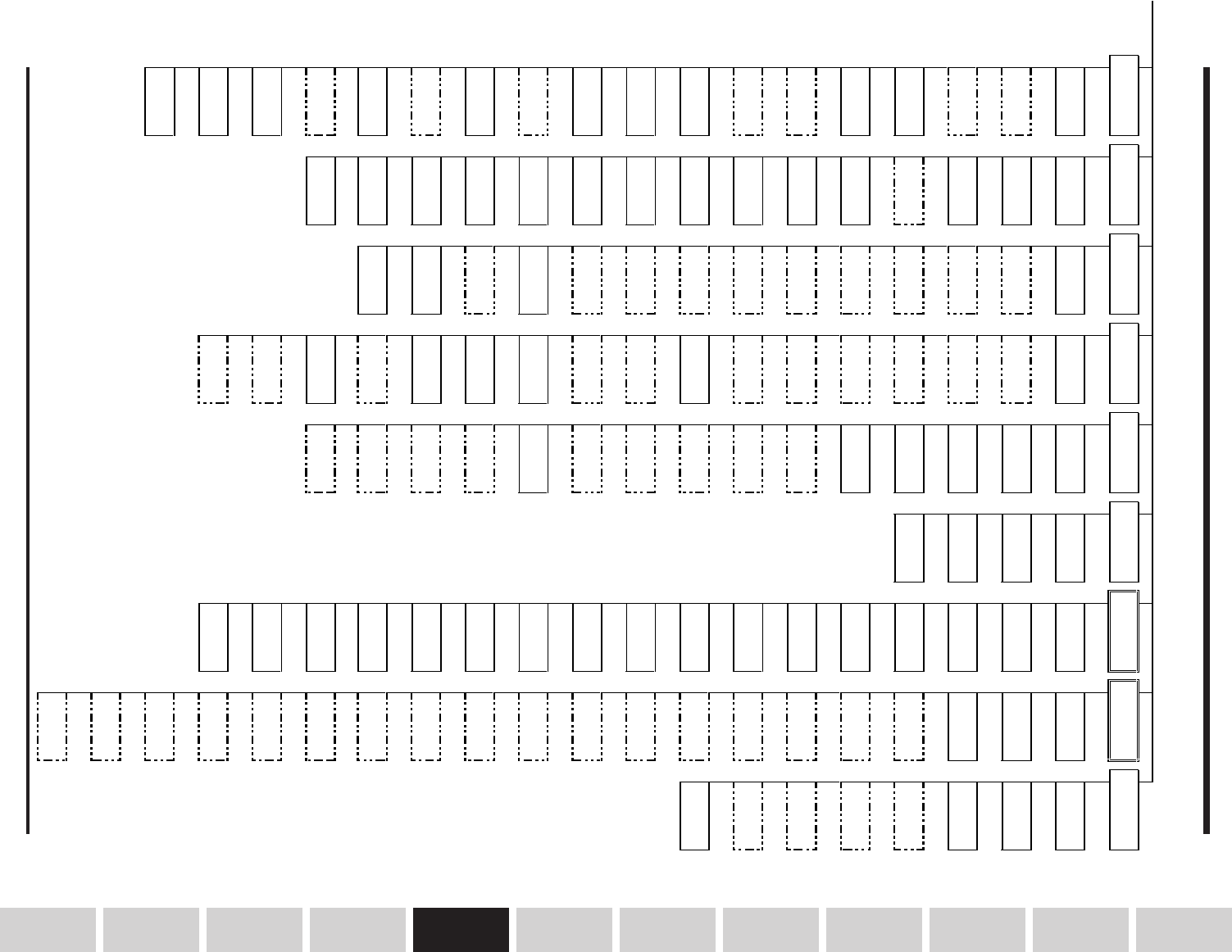

Parameter Tree (cont'd)

Protection Parameters Protection Parameters

(Continued)

Pattern Run Control

Parameters

Feedback Parameters Communication Setting

Parameters

AM/FM Terminal

Adjustment Parameters

Utility Parameters Utility Parameters

(Continued)

Motor Parameters

142 160 175 243 260 275 279 296 316

Dynamic Braking

Selection

Motor 150% Overload

Time Limit

Pattern Run Selection Feedback Control

Selection

RS232 Baud Rate FM Terminal Function

Selection

Industrial Applications Current Units Selection Number of Motor Poles

143 161 176 244 261 276 280 297 317

Branking Resistor

Value

Overload Selection Pattern Run Continue

Mode

Feedback Input Signal

Selection

Number of Data Bits Frequency Meter

Adjustment

Standard Setting Mode

Selection

Voltage Units

Selection

Motor Rated Capacity

144 162 177-184 245 262 277 281 298 318

Braking Resistor

Power Rating

Stall Protection Enable Pattern Group #1

Speeds #0 - #7

Proportional Gain Parity Setting AM Terminal Function

Selection

Command Mode

Selection

Blind Function

Selection

Motor Type

145 163 185 246 263 278 282 299 319

Overvoltage Stall

Protection

Stall Protection

Current Level

Pattern Group #1

Number of Cycles

Integral Gain Inverter ID Number Current Meter

Adjustment

Frequency Mode

Selection

Fundamental

Parameters #2 Blind

Motor Rated Voltage

146 164 186-193 247 264 283 300 320

DC Injection Start

Frequency

Undervoltage Trip

Selection

Pattern Group #2

Speeds #0 - #7

Anti Hunting Gain Communication

Selection

Panel Operation Mode

Selection

Panel Control

Parameters Blind

Motor Rated

Frequency

147 165 194 248 265 284 301 321

DC Injection Current

Magnitute

Undervoltage Detect

Time

Pattern Group #3

Number of Cycles

Lag Time Constant Master/Slave Selection Pass Number Terminal Selection

Parameters Blind

Motor Rated RPM

148 166 195-202 249 266 285 302 322

DC Injection Time Low Current Detect

Selection

Pattern Group #3

Speeds #0 - #7

PID Lower Frequency

Limit

RS485 Baud Rate CPU Version Special Control

Params Blind

Auto-Tuning Enable

149 167 203 250 267 286 303 323

Fwd/Rev DC Inj.

Priority control

Low Current Detect

Level

Pattern Group #3

Number of Cycles

PID Deviation Limit

Selection

TOSLINE F10/S20

Command Input

ROM Version Frequency Setting

Params Blind

Load Moment of Inertia

150 168 204-211 251 268 287 304

Motor Shaft stationary

control

Low Current Detection

Time

Pattern Group #4

Speeds #0 - #7

PID Deviation Upper

Limit

TOSLINE F10/S20

Monitor Output

EEPROM Version Protection Function

Params Blind

151 169 212 252 269 288 305

Emergency Off Mode

Selection

Output Short Circuit

Detection Select

Pattern Group #4

Number of Cycles

PID Deviation Lower

limit

TOSLINE F10/S20

Comm Error Mode

Inverter TypeForm Pattern Run Control

Params Blind

152 170 213 253 270 289 306

Emergency Off DC

Injection Time

Overtorque Trip

Selection

Speed #1 Continue

Mode

PG Input Number of

Pulses

RS485/12-Bit Binary

Bias, Gain

Status Monitor #1

Display Select

Feedback Control

Params Blind

153 171 214 254 271 290 307

Number of Retry

Attempts

Overtorque Trip Level Speed #1 Drive Time PG Input Number of

Phases

RS485/12-Bit Binary

point #1

Status Monitor #2

display Select

Communication

Params Blind

154 172 215-242 255 272 291 308

Time Between Retry

Attempts

Fault Trip EEPROM

Save Enable

Speeds 2 - 15 Drive

Time

Drooping Control

Enable

RS485/12-Bit Binary

pt. #1 Freq

Status Monitor #3

Display Select

Industrial Appl: Pump

Params Blind

155 173 215 - 242 256 273 292 309

Regeneration Power

Ride Through

Cooling Fan Control

Selection

Speeds 2-15 Continue

mode

Drooping Control

Amount

RS485/12-Bit Binary

point #2

Status Monitor #4

Display Select

Industrial Appl: Fan

Params Blind

156 174 257 274 293 310

Regeneration Ride

Through time

Cumulative Run Timer

Alarm Setting

Override Control

Selection

RS485/12-Bit Binary

pt. #2 Freq

Frequency Units Scale

Factor

Industrial Appl:

Conveyor Blind

157 258 294 311

Auto-restart (motor

speed search)

Override Multiplier

Input Selection

Frequency Display

Resolution

Industrial Appl: Hoist

Blind

158 259 295 312

Electronic Thermal

Protect Level 1

Override Change

Multiplier

ACC/DEC Time Units

Selection

Industrial Appl:

Textiles Blind

159 313

Overload Reduction

Start Freq.

Industrial Appl: Tools

Blind

314

AM/FM Adjustment

Params Blind

315

Motor Parameters

Blind

Specifications

Precautions

Wiring

JumpersPanelKeypadParametersProgrammingServiceDimensionsIndex Inspection