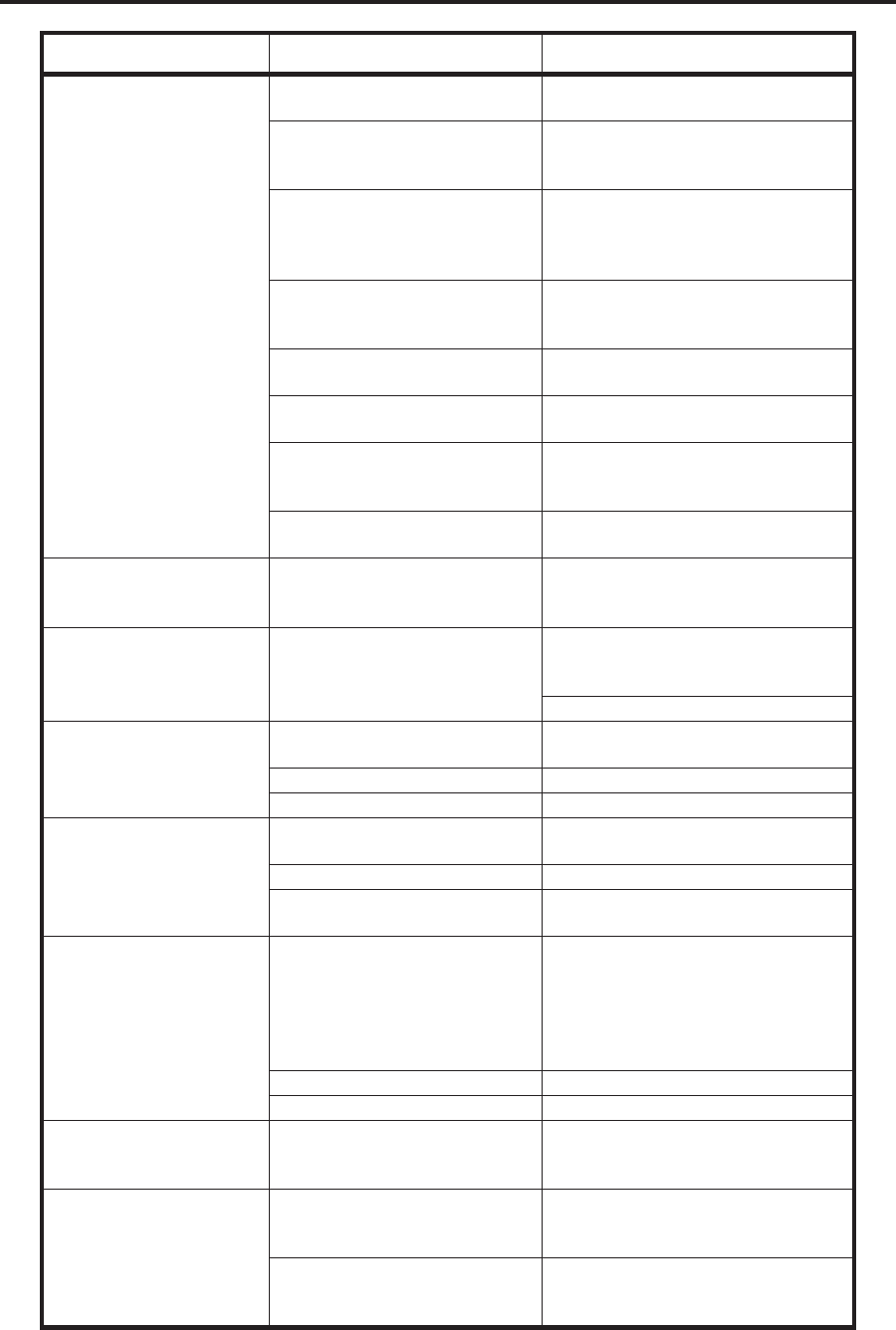

SYMPTOM DIAGNOSIS ACTION

Wrinkled ribbon. Ribbon fed through the

machine incorrectly.

See “Ribbon Loading” on

page 5.

Incorrect burn

temperature.

Set the burn temperature to

the lowest possible setting for

good print quality.

Incorrect or uneven

printhead pressure.

Set the pressure to the

minimum needed. See

“Printhead Pressure”

adjustment on page 35.

Media not feeding

properly; “walking” from

side to side.

Make sure that the media is

snug by adjusting the Media

Guide, or call a service tech.

Strip Plate needs

adjusting.

Call a service technician.

Printhead needs vertical

adjustment.

Call a service technician.

Printhead and Platen

Roller need to be

realigned.

Call a service technician.

Ribbon Supply Spindle

motor is inoperative.

Call a service technician.

Broken or melted

ribbon.

Darkness setting too high. Reduce setting for best print

quality, and clean the

printhead thoroughly.

Light printing or no

printing on the left or

right side of the label.

Printhead pressure needs

adjustment or printhead

out of alignment.

See “Printhead Pressure”

adjustment on page 35.

Call a service technician.

Misregistration/skips

labels.

Media Sensor is not

positioned correctly.

Perform Media Sensor

position adjustment.

Printer not calibrated. Recalibrate printer.

Improper label format. Use correct label format.

Misregistration and

misprint of one to

three labels.

Media Sensor is not

positioned correctly.

Place Media Sensor in proper

position.

Dirty Platen. Clean the Platen.

Media does not meet

specifications.

Use media that meets

specifications.

Vertical drift in

top-of-form

registration.

A plus or minus 4-6 dot row

(approximately 0.5 mm)

vertical drift is acceptable

due to the different toler-

ances of the mechanical

parts and printer modes.

First calibrate the printer, then

use the “Label Top Position”

setting to correct. See

“Configuration and

Calibration.”

Printer out of Calibration. Recalibrate printer.

Platen dirty. Clean Platen.

Missing LCD

characters or parts of

characters.

Liquid Crystal Display

may be bad and need

replacing.

Call a service technician.

Changes in

parameter settings

did not take effect.

Parameters are set

incorrectly.

Set parameters and save

permanently. Cycle the printer

power OFF and back ON.

If problem continues,

there may be a problem

with the main logic board.

Call a service technician.

40 170PAX2-Series User’s Guide

Troubleshooting