Thermal/Mechanical Specifications and Design Guidelines 113

Mechanical Drawings

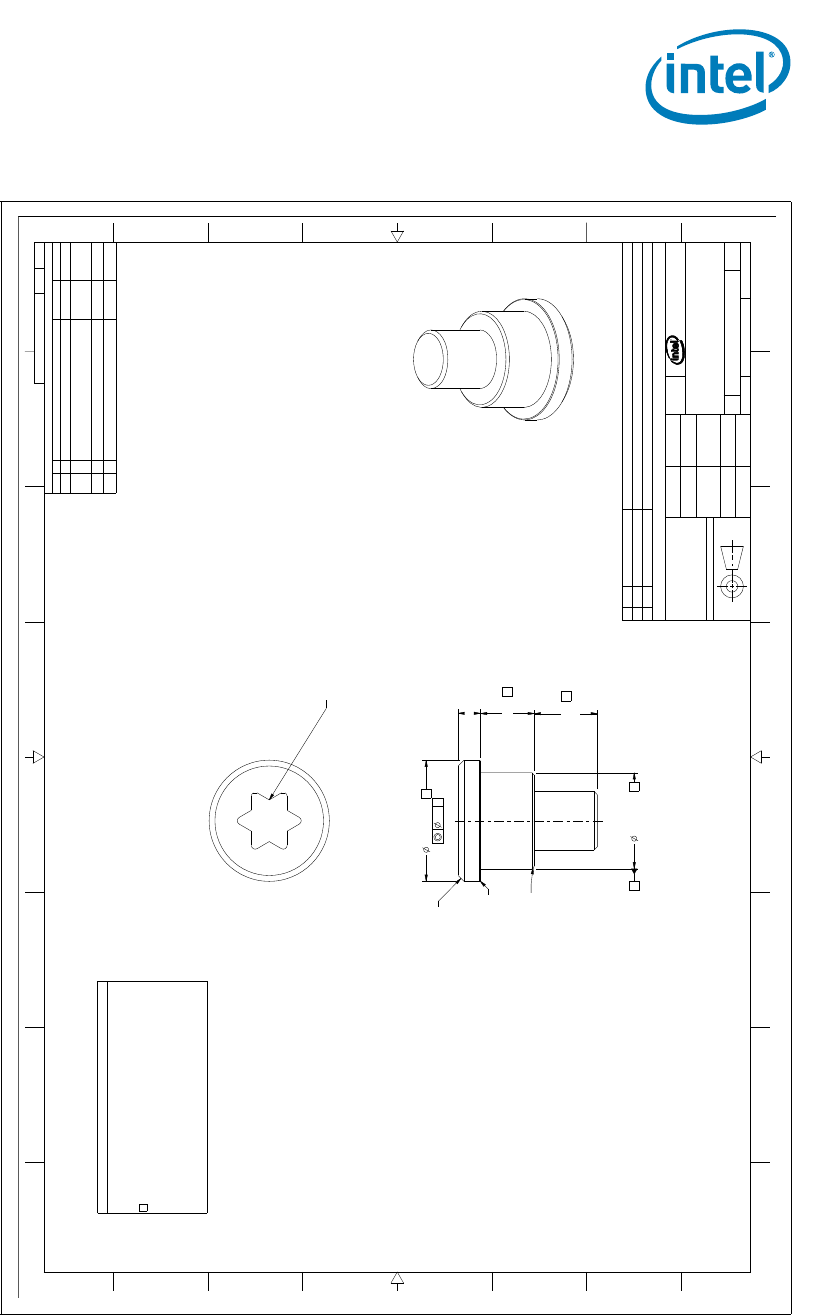

Figure B-18. 1U ILM Shoulder Screw

8 7 6 5 4 3 2

H

G

F

E

D

C

B

A

8 7 6 5 4 3 2 1

H

G

F

E

D

C

B

A

A 35.75± 0.05

0.1 A

37.25± 0.05

1.35±0.1

33.25± 0.05

3

6-32 UNC CLASS 2A THREAD

3.8± 0.2

45° X 0.35 ± 0.1

45° X 0.05

+0.2

0

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

1 A INITIAL RELEASE 11/01/08

2B

DECREASE .1MM TO SHOULDER HEIGHT;

UPDATED PLATING SPEC

02/20/09

3 C ADD CTF TO THREAD LENGTH 06/10/09

4

D UPDATED TO BLACK NICKEL PLATING 07/06/09

E49065-001 1 D

DWG. NO SHT. REV

DEPARTMENT

R

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

EASD-SH

TITLE

FOXHOLLOW SERVER ILM SHOULDER SCREW

SIZE DRAWING NUMBER REV

A1

E49065-001

D

SCALE:

13

DO NOT SCALE DRAWING

SHEET

1

OF

1

SEE NOTESSEE NOTES

FINISHMATERIAL

DATEAPPROVED BY

DATECHECKED BY

05/19/08JUN LU

DATEDRAWN BY

05/19/08JUN LU

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

ALL UNTOLERANCED LINEAR

DIMENSIONS ±0.1

ANGLES ±1

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTIONPART NUMBERITEM NOQTY

FOXHOLLOW 1U ILM SHOULDER SCREWTOP

6 POINT T-20 DRIVE

HEAD DEPTH 2MM MIN

45° X 0.15+/- 0.1

NOTES:

1. THIS DRAWING TO BE USED IN CONJUNCTION WITH THE SUPPLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS DRAWING

TAKE PRECEDENCE OVER SUPPLIED FILE.

2. UNLESS OTHERWISE NOTED, TOLERANCES ON DIMENSIONED FEATURES

ARE AS IN TOLERANCE BLOCK.

3 CRITICAL TO FUNCTION (CTF).

4. MATERIAL: LOW CARBON STEEL,

MIN HARDNESS - ROCKEWELL HARDNESS B70.

5. PLATING: 2 MICRON MIN. ELECTROLYTIC "BLACK" NICKEL PLATING.

PROCESS TEST: 48 HRS. 85° C/85% HUMIDITY WITH NO VISIBLE CORROSION.

6. REMOVE ALL BURRS OR SHARP EDGES AROUND PERIMETER OF PART.

SHARPNESS OF EDGES SUBJECT TO HANDLING ARE REQUIRED TO MEET

UL1439 TEST.

7. BREAK ALL SHARP CORNERS, EDGES, AND BURRS TO 0.10MM MAX.

8. PART SHALL BE DEGREASED AND FREE OF OIL AND DIRT MARKS.