LGA1155 Socket

24 Thermal/Mechanical Specifications and Design Guidelines

Cover retention must be sufficient to support the socket weight during lifting,

translation, and placement (board manufacturing), and during board and system

shipping and handling. PnP Cover should only be removed with tools, to prevent the

cover from falling into the contacts.

The socket vendors have a common interface on the socket body where the PnP cover

attaches to the socket body. This should allow the PnP covers to be compatible between

socket suppliers.

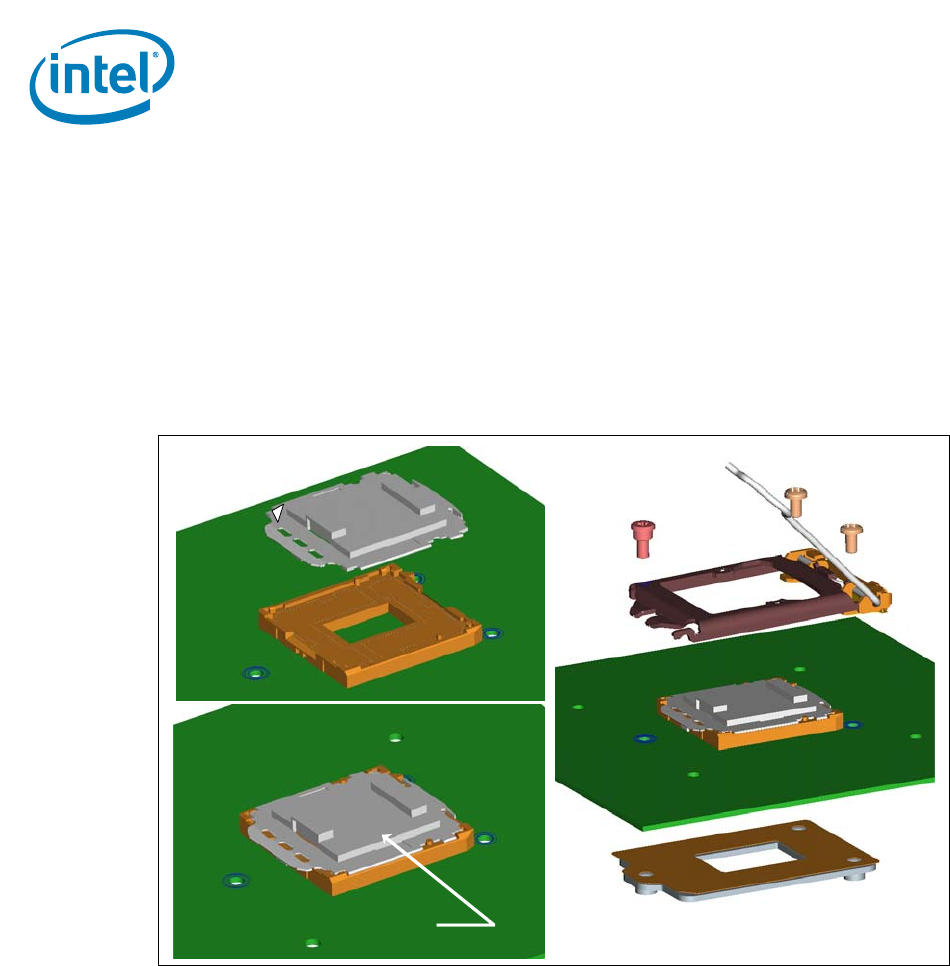

As indicated in Figure 3-6, a Pin 1 indicator on the cover provides a visual reference for

proper orientation with the socket.

3.4 Package Installation / Removal

As indicated in Figure 3-7, access is provided to facilitate manual installation and

removal of the package.

To assist in package orientation and alignment with the socket:

• The package Pin1 triangle and the socket Pin1 chamfer provide visual reference for

proper orientation.

• The package substrate has orientation notches along two opposing edges of the

package, offset from the centerline. The socket has two corresponding orientation

posts to physically prevent mis-orientation of the package. These orientation

features also provide initial rough alignment of package to socket.

• The socket has alignment walls at the four corners to provide final alignment of the

package.

Figure 3-6. Pick and Place Cover

Pick & Place Cover

Pin 1

ILM Installation

Pick & Place Cover

Pin 1

ILM Installation