Thermal/Mechanical Specifications and Design Guidelines 29

Independent Loading Mechanism (ILM)

4.1.3 Shoulder Screw and Fasteners Design Overview

The shoulder screw is fabricated from carbonized steel rod. The shoulder height and

diameter are integral to the mechanical performance of the ILM. The diameter provides

alignment of the load plate. The height of the shoulder ensures the proper loading of

the IHS to seat the processor on the socket contacts. The design assumes the shoulder

screw has a minimum yield strength of 235 MPa.

A dimensioned drawing of the shoulder screw is available for local sourcing of this

component. Please refer to Figure B-18 for the custom 6-32 thread shoulder screw

drawing.

The standard fasteners can be sourced locally. The design assumes this fastener has a

minimum yield strength of 235 MPa. Please refer to Figure B-19 for the standard 6-32

thread fasteners drawing.

The screws for Server ILM are different from Desktop design. The length of Server ILM

screws are shorter than the Desktop screw length to satisfy Server secondary-side

clearance limitation. Server ILM back plate to use black nickel plated screws, whereas

desktop ILM back plate to use clear plated screws. Unique part numbers, please refer

to Appendix A.

Note: The reference design incorporates a T-20 Torx head fastener. The Torx head fastener

was chosen to ensure end users do not inadvertently remove the ILM assembly and for

consistency with the LGA1366 socket ILM.

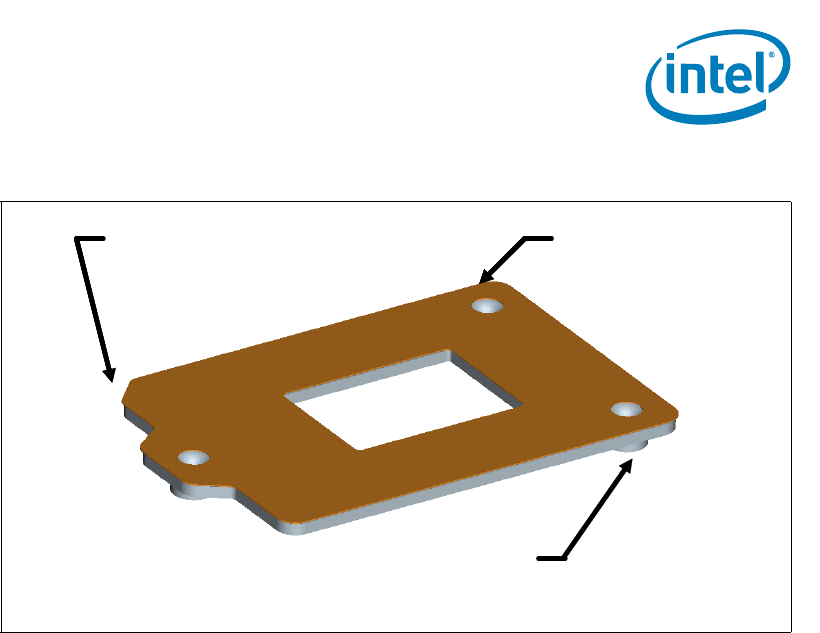

Figure 4-2. Back Plate

Die Cut

Insulator

Pierced & Extruded

Thread Features

Assembly

Orientation

Feature

Die Cut

Insulator

Pierced & Extruded

Thread Features

Assembly

Orientation

Feature