Exatron 3000B

www.exatron.com 7-8 Chapter 7 Preventive Maintenance

General Solenoid Maintenance Guidelines

1. Keep the solenoids as clean as possible.

2. If the handler is used with devices which have excessive mold flash, the solenoids will require

cleaning regularly. The frequency is dependent upon how much mold flash gets into the solenoids.

3. NEVER use oil or lubricant of any kind on solenoids.

4. When cleaning solenoids, take care not to put excessive stress on solenoid wiring. Check all wiring

for signs of wear, exposed conditions, or broken connections. Replace as needed with identical type

of wire: standard or flex, same gauge, insulation, color, etc.

5. When cleaning solenoids, check the plungers to be sure there are no burrs of any kind on their shafts.

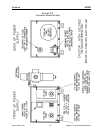

6. When mounting #SP75 or #SP62 open frame solenoids, use #40-40 screws. It is very important to

not use screws which are too long and may therefore cut into the solenoid's coil. Since the handler is

grounded, metal screws touching the coil would create a massive short circuit when the solenoid is

turned on.

7. NEVER put a metal washer between the plunger/coil of a #SP75 or #SP62 open frame solenoid and

the return spring. This will cause solenoid jams. The washer will be attracted magnetically to the

body of the solenoid and will act like a brake on the solenoid plunger.

8. Wherever possible, adjust the solenoid travel/movement to be as short as possible. The solenoid

power is exponentially proportional to the solenoid travel.

9. When replacing wiring on solenoids which travel, such as those on door assemblies and shuttles,

always use high-flex wire. We recommend 22 AWG 150 strand high-flex wire.

10. Solenoid life is proportional to the handler environment and how often the solenoids are cleaned. We

recommend that all solenoids be replaced every two million cycles as part of a good preventive

maintenance program.

11. Replace any bent or damaged solenoid return springs with new parts from the E

XATRON

factory.

12. Refer to the hardware specifications of the Replacement Parts Chapter of this manual for the part

numbers of all solenoids and springs in your handler.

13. Use the solenoid diagnostic routine for proper solenoid movement. Please refer to the Handler

Diagnostics Chapter of this manual for details.