Exatron 3000B

www.exatron.com 2-10 Chapter 2 Installation

Environmental Operating Specifications

Location

ALL "BENCHTOP" (ALSO KNOWN AS "TABLE TOP," "PLATE MOUNTED") HANDLERS MUST BE

BOLTED SECURELY TO THE TOP OF THE BENCH.

The handler's center of gravity is fairly high in

relation to the benchtop. This makes the handler unstable if not bolted down, which could result in the

handler being knocked over. This can cause serious damage to the handler and injury to the user.

This machine should be installed in a dust-free environment to preclude dust and dirt particles from

contaminating its moving parts, especially those parts which come into contact with the devices being

tested. The life of your handler is greatly enhanced by keeping it as clean as possible.

This Model 3000B handler should be placed as close as possible to your tester test socket, since cable

length from the contactor to the tester is critical in most applications. Please refer to Chapter 3 Interface

Information, for further details.

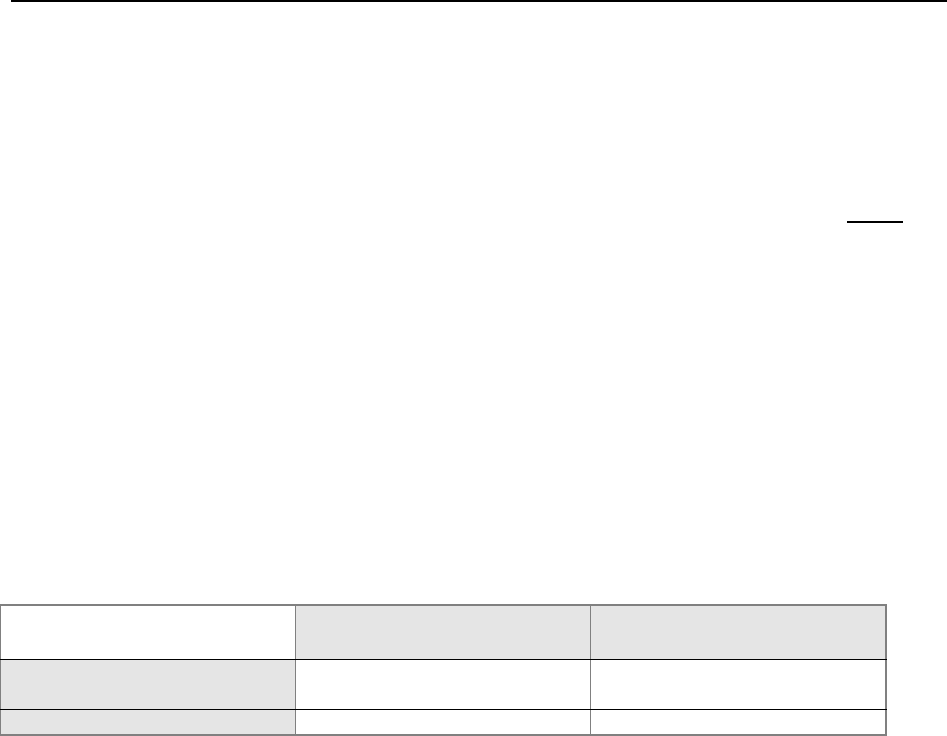

As specified in the table shown below, Exatron handlers are designed to withstand the impact of virtually

any climate and/or environment that they may be used in. Periodic maintenance as prescribed in Chapter

7 of this manual will ensure that emergency "down time" is kept to a minimum.

Handler/Hot Rail Handler with Printer

Temperature

40° to 115° F,

5° to 45° C

40° to 105° F,

5° to 40° C

Relative

Humidity

20% to 85%, Noncondensing 20% to 80%, Noncondensing

Airborne dust and moisture, if present, will naturally settle on all surfaces of your handler. If allowed to

build up, dust can eventually block sensors, clog solenoids, fill up the filters of cooling fans, vacuum

generators, air filters and generally inhibit the smooth movement of devices through the handler.

The best defense against this kind of contaminate is to install and use your handler in a dust-free

environment to preclude dust and dirt particles from contaminating its moving parts, especially those parts

which come into contact with the devices being tested. If dust is a factor in your operating environment,

dust the handler off with blasts of compressed air at least every 8 hours. Make sure that the compressed

air is clean, dry and free of any oil.

ESD Grounding

All Model 3000B Handlers meet or exceed all known device manufacturers' ESD specifications. All 3000B

Series Handler chassis' are directly connected through the power supply to earth ground. All guide rails,

shuttles, tube holders, hot rails and output trays are connected to earth ground. The handler's power

supply ground is directly connected to earth ground. The handler power supply MUST be connected to a

properly grounded power outlet. NEVER operate the handler with the power line ground removed or

defeated.

All handler main plates, covers and non-trackwork handler parts are plated with conductive finishes.

Exatron uses a very limited quantity of anodizing finishes on handler surfaces.