Exatron 3000B

www.exatron.com 3-3 Chapter 3 Interface Info

Pick Up Delay: Address 00A9

This delay allows additional time after the handler has detected the device under the plunger before

turning on the vacuum to pick up the DUT at the start of the test cycle. The delay counts down in HEX, in

10 millisecond steps. This feature applies to Plunge-to-Board and Swing Head changeover kits only.

Stop On Fail Y/N: Address 00AA

30 = Stop on Fail

FF = Run Failed Devices, No Stop

This option allows the handler to Stop on Fail, or not. The handler can either automatically cycle a failed

device into an output tube or the handler can be set to stop. If set to

STOP ON FAIL YES

, then the

handler will stop on a failure and allow the operator to retest the device again and again, as often as

desired. This is very useful when calibrating test fixtures and programs.

Gate Delay: Address 00AB

This delay allows additional time for the test site gate to first open and then secondly, allows additional

time after the handler closes the gate at the end of the test cycle. The delay counts down in HEX, in 10

millisecond steps. This feature applies to Plunge-to-Board changeover kits only.

Double Test Sort: Address 00BC

This address tells the handler which test sorts to double test if desired. A setting of “

00

” will turn

off

the

double test for all sorts. A setting of “

FF

” will set the tester to double test

all

devices. Assuming Sort 1 is

Pass and all other sorts are to be double tested, set this address to “

FE

.” Each bit represents a tester sort.

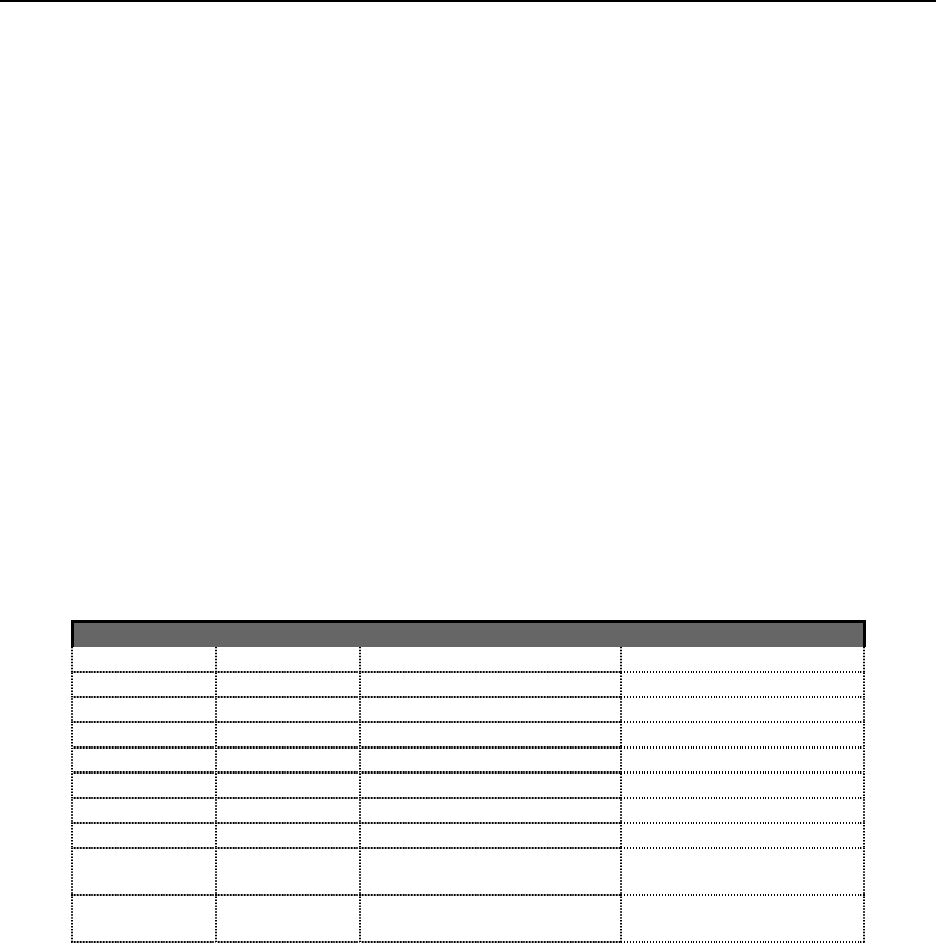

Tester Sort Set Up: Addresses 00C0 to 00C7

ASCII I

NPUT

S

ORT

O

UTPUT

B

INS

C

URRENT

S

ETTING

1

1 RAM ADDRESS C0

2

2 RAM ADDRESS C1

3

3 RAM ADDRESS C2

4

4 RAM ADDRESS C3

5

5 RAM ADDRESS C4

6

6 RAM ADDRESS C5

7

7 RAM ADDRESS C6

8

8 RAM ADDRESS C7

✻

✻✻

✻

= Remote Flush

USED BY EXATRON RS

-

232

AND H P RS

-

232 ONLY

0

= Remote Retest

USED BY EXATRON RS

-

232

AND H P RS

-

232 ONLY

The handler uses the specifications shown in the table above to assign Output Bins to tester Sorts.

The “Current Setting” column is provided for the customer’s reference purposes. Please enter your

settings in this column.

If the handler does not receive one of the above test Sorts, the handler will pause and display the

message, “

BAD TEST RESULT

.” The handler will output the HEX equivalent of the actual character

received by the handler to the LEDs on the handler’s output shuttle cover. LED #1 is bit 01, LED #8 is bit

80. Pressing the

[Clear]

button on the handler’s front panel will flush the device from the test site and

restart operation. Press

[Enter]

to retest, if desired.

When the handler does receive a proper result in the form of one of the above test Sorts, the handler will

open the test contacts and flash the output cover LED of the output bin selected. The handler will sort the

DUT accordingly and start a new handling cycle.