66

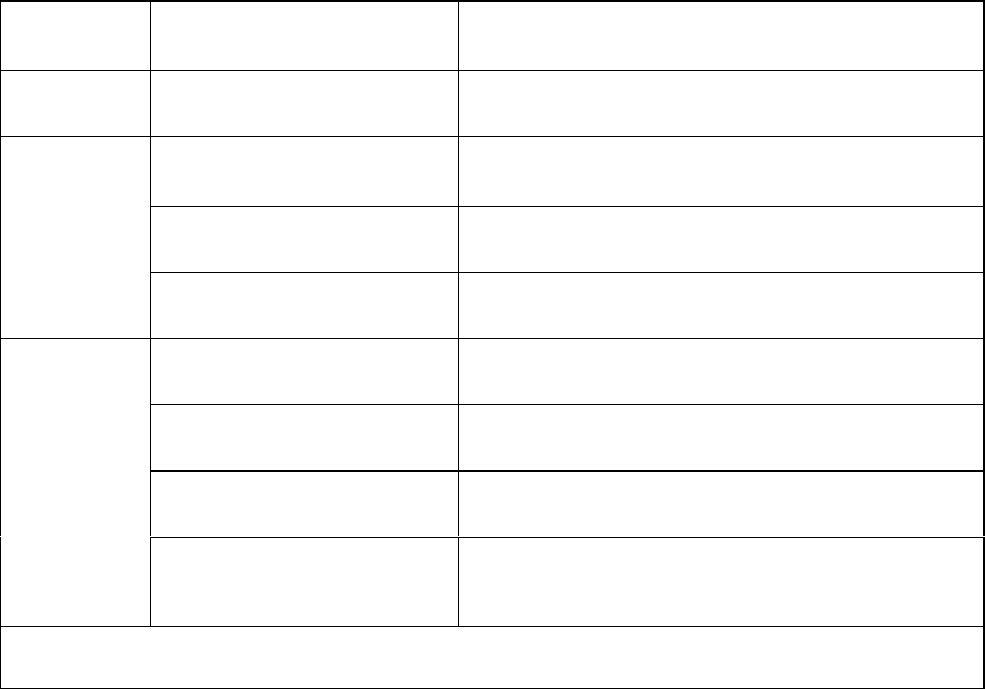

Function Example of Equipment Operating Panel

Classificati

on

Part Application

Display

Display

Displays messages, such as ROBOT PREPARATION

OK.

Q Automatic operation

indicator lamp

⋅ Lights during automatic operation.

⋅ Turned OFF when the robot is not in automatic

operation.

R Robot external mode

indicator lamp

⋅ Lights when the robot is in external mode.

⋅ Turned OFF when the robot is not in external mode.

Lamp

S Operation OK indicator

lamp

⋅ Lights when the Enable Auto signal is ON.

⋅ Turned OFF when the Enable Auto signal is OFF.

Q Robot preparation button Starts the preparation of the robot.

R Automatic start button Starts the operation of the equipment.

S Cycle stop button

Stops the equipment after a cycle of operations is

completed.

Switch

T Operation/Adjustment

selector switch

Automatic operation of the robot possible when

OPERATION is selected.

Manual operation or teach check of the robot possible

when ADJUSTMENT is selected.

Caution: Actual equipment requires emergency stop, interlock and other functions; however,

described here are the necessary functions.

(2) Outline of procedure

Described below is the outline of the procedure when using the equipment

taken as an example shown on the previous page.

Follow steps to .

Operation preparation start

After setting the MOTOR ON, CAL EXECUTION, EXTERNAL SPEED

100 and EXTERNAL MODE SWITCHING bits, execute the mode

switching command to bring the robot into external automatic operation

mode. This operation will be completed when the EXTERNAL MODE

output signal is turned ON.

Automatic operation

Start the program by which the robot starts from the operation origin,

performs operations, and returns to the operation origin.

Operation end

Terminate the day’s operations with a cycle stop, and turn OFF the

power.

(3) Start and stop procedure, and system I/O signals

The following pages show the relationship between the system I/O signals

for start and stop, worker’s operation, display on the equipment operation

panel, PLC proceeding, and robot motion.