Closed Loop Position Mode

96 AX3500 Motor Controller User’s Manual Version 1.9b. June 1, 2007

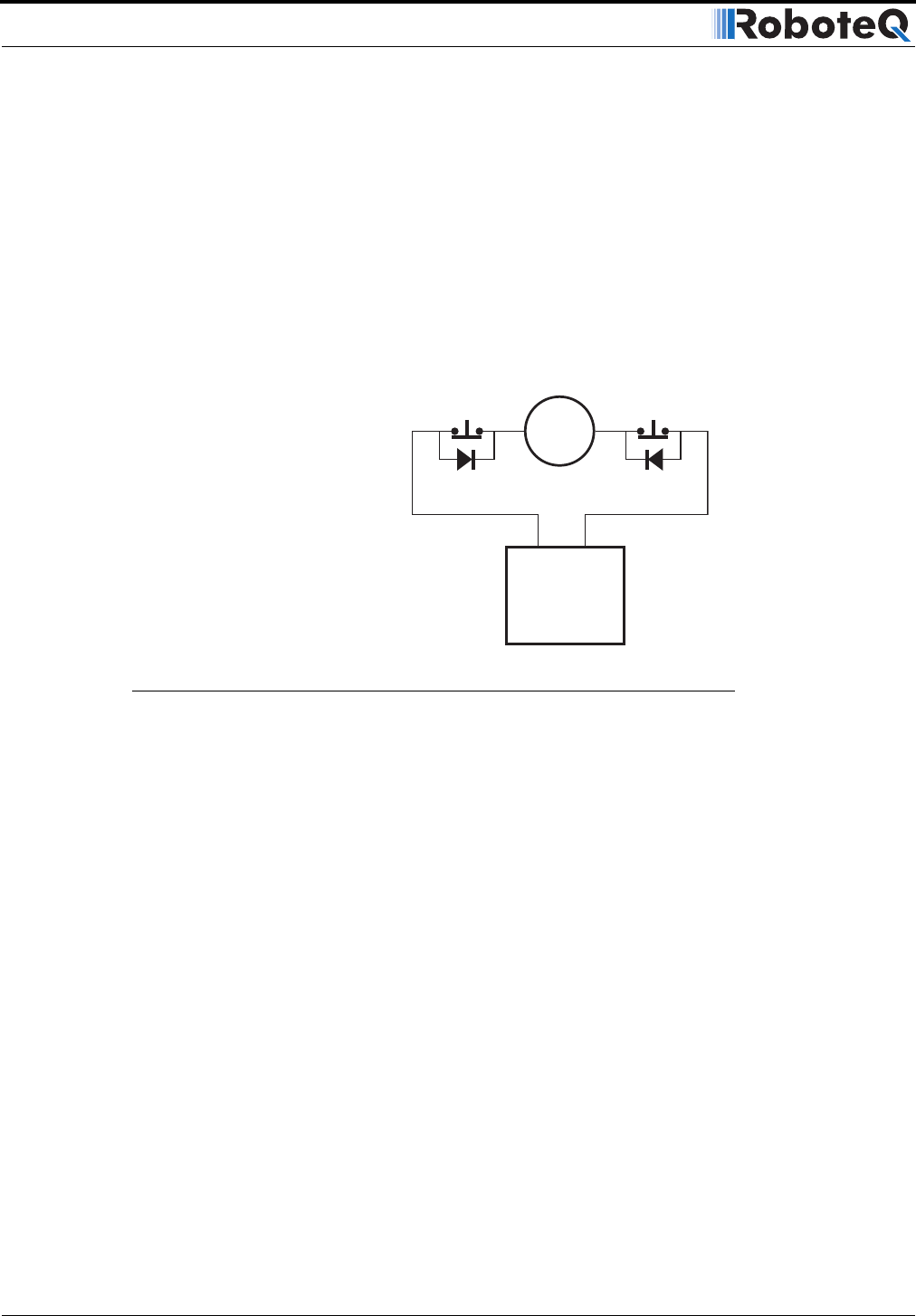

The diode polarity depends on the particular wiring and motor orientation used in the appli-

cation. If the diode is mounted backwards, the motor will not stop once the limit switch

lever is pressed. If this is the case, reverse the diode polarity.

The diodes may be eliminated, but then it will not be possible for the controller to move the

motor once either of the limit switches has been triggered.

The main benefit of this technique is its total independence on the controller’s electronics

and its ability to work in practically all circumstances. Its main limitation is that the switch

and diode must be capable of handling the current that flows through the motor. Note that

the current will flow though the diode only for the short time needed for the motor to move

away from the limit switches.

Another method uses the AX3500’s Emergency Stop input to shut down the controller if

any of the limit switches is tripped. Figure 63 shows the wiring diagram used in this case.

Each of the limit switches is a Normally Open switch. Two of these switches are typically

required for each motor. Additional switches may be added as needed for the second

motor and/or for a manual Emergency Stop. Since very low current flows through the

switches, these can be small, low cost switches.

The principal restriction of this technique is that it depends on the controller to be fully

functioning, and that once a switch is activated, the controller will remain inactive until the

switch is released. In most situations, this will require manual intervention. Another limita-

tion is that both channels will be disabled even if only one channel caused the fault.

Motor

SW1 SW2

Controller

FIGURE 62. Safety limit switches interrupting power to motors