8 - 4

8

e-STUDIO350/352/353/450/452/453

LASER OPTICAL UNIT

© 2003 - 2008 TOSHIBA TEC CORPORATION All rights reserved

(2) Polygonal motor unit

This unit consists of the polygonal motor, polygonal mirror and polygonal mirror cover.

a. Polygonal motor

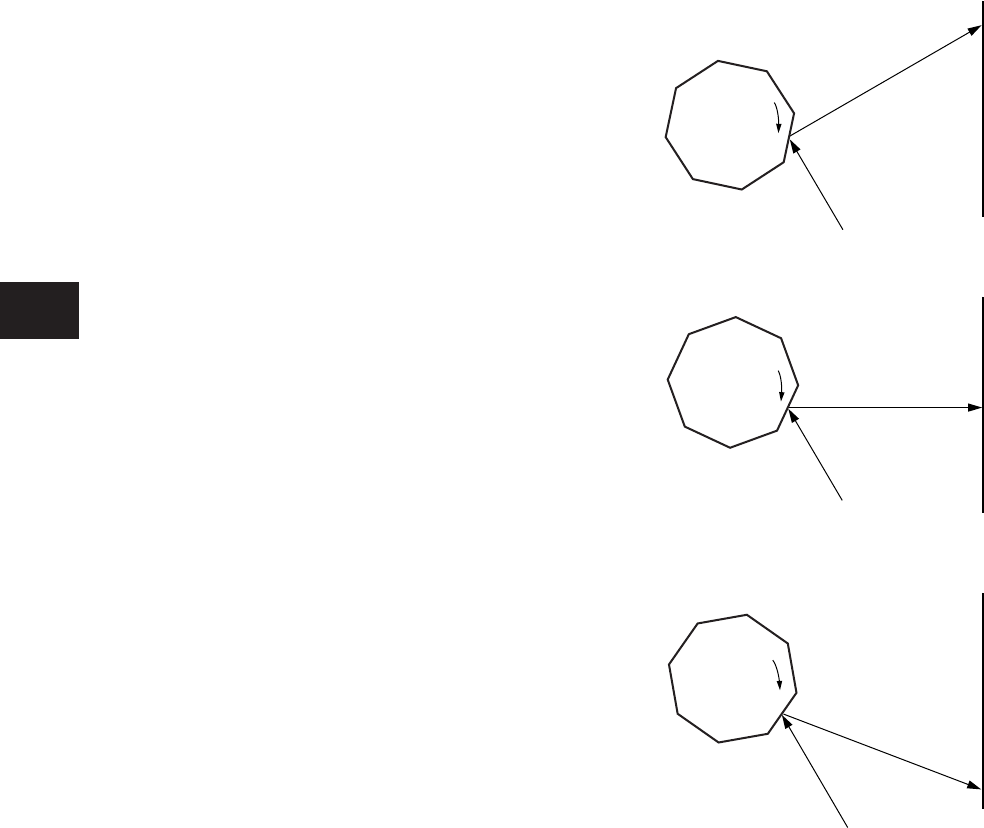

One scan is completed by completion of steps (A) to (C).

One scan is performed on one plane of the polygonal-

mirror. Eight scans can be made with one rotation of

the polygonal mirror.

Fig. 8-202

(

A

)

Drum

Laser beam

(

B

)

Drum

Laser beam

(

C

)

Drum

Laser beam

This motor rotates the polygonal mirror in

high speed.

The DC motor controls the rotation speed

of the mirror motor as follows:

During ready: 10,000.00 rpm

During printing: 38,090.55 rpm (600dpi)

:

38,951.37 rpm (FAX 15.4

×

16.0 dot/mm)

:

37,490.70 rpm (FAX 16.0

×

15.4 dot/mm

)

b. Polygonal mirror

One laser beam emitted from the laser

diodeisreectedbythismirror.Asthe

polygonal mirror is rotated by the po-

lygonalmotor,thereectedlaserbeam

moves in sync with the rotation. The

direction of the movement is the primary

scanning direction of the image. One

scan is performed on one plane of the

polygonal mirror.

As the polygonal mirror has eight planes,

eight scans are performed in one rotation

of the polygonal mirror.

c. Polygonal mirror cover

Polygonal mirror cover reduces the wind-

age loss and noise, prevents adhesion

of foreign objects onto the mirror surface

and releases heat.