3 - 1 e-STUDIO350/352/353/450/452/453

COPY PROCESS

3

© 2003 - 2008 TOSHIBA TEC CORPORATION All rights reserved

3. COPY PROCESS

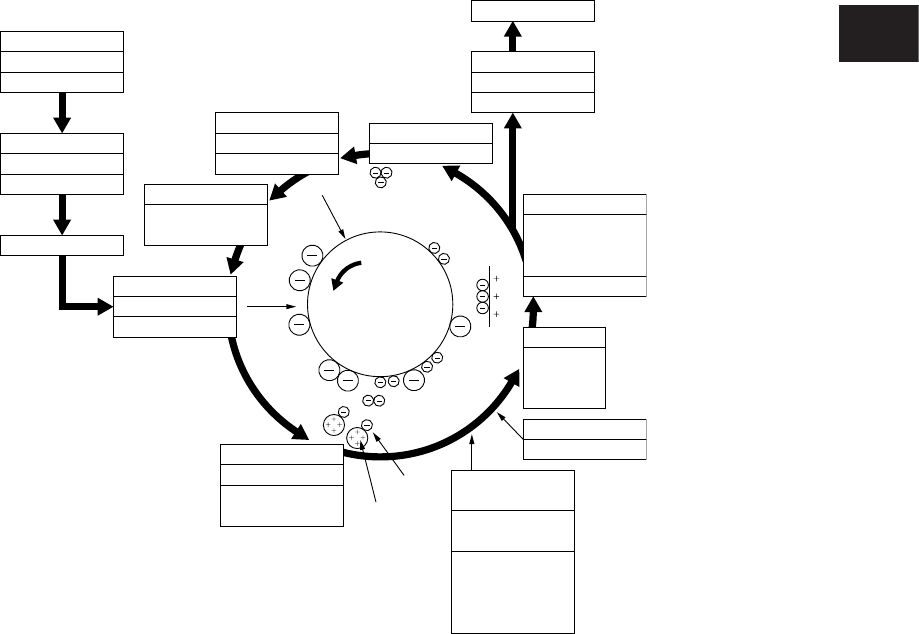

3.1 General Description of Copying Process

(1) Charging: Applies negative charge on the

surface of the photoconductive drum.

(2) Original exposure: Converts images on the

original into optical signals.

(3) Data reading: The optical signals are con

-

verted into electrical signals.

(4) Data writing: The electrical signals are

converted into light signal (laser emission)

which exposes the surface of the photocon

-

ductive drum.

(5) Development: Negatively-charged toner

adheres to the photoconductive drum and

forms visible image.

(6) Transferbias:Improvestransferefciency.

(7) Transfer: Transfers the visible toner image

on the photoconductive drum onto paper.

(8) Separation: Separates paper with the toner

image from the photoconductive drum.

(9) Fusing: Fuses the toner image onto the pa

-

per by applying heat and pressure.

(10) Cleaning : Scrapes off the residual toner

from the drum.

(11) Discharging : Eliminates the residual nega

-

tive charge from the surface of the

photoconductive drum.

Original exposure

Xenon lamp

16W

Data reading (scanning)

CCD

600 dpi, 7400 pixel

Image processing

(2)

(3)

(4)

Discharging

Discharge LED (red)

Wavelength 660nm x14pcs

(11)

Data writing

Semiconductive laser

Pw=4.3 nJ/mm

2

Charging

–790V

(grid voltage)

Development

Magnetic roller

Bias –550VDC

+150VDC

(1)

(5)

Toner

Carrier

Cleaning

Blade method

(10)

Bypass feeding

(100 sheets)

PFP (upper/lower)

(550 sheets) or

LCF

(1250 sheets x 2)

Drawer feeding

(upper/lower)

(550 sheets)

Transfer

H 286 uA

C 286 uA

L 137 uA

Separation

ACH 5.5kV

C 4.0kV

L 2.5kV

DC -100V

1kHz

Paper exit

Fusing

Inductionheating (IH) method

700~1240W

Transfer bias

DC+580V

(9)

(8)

(7)

(6)

Fig. 3-101