1-10

1. OUTLINE OF THE SYSTEM

EM10-33006A

1.5 ELECTRONICS SPECIFICATIONS

External controller, etc.

(In case of photo-coupler)

~

~

Printer

OUT0

OUT5

COM2

Vcc

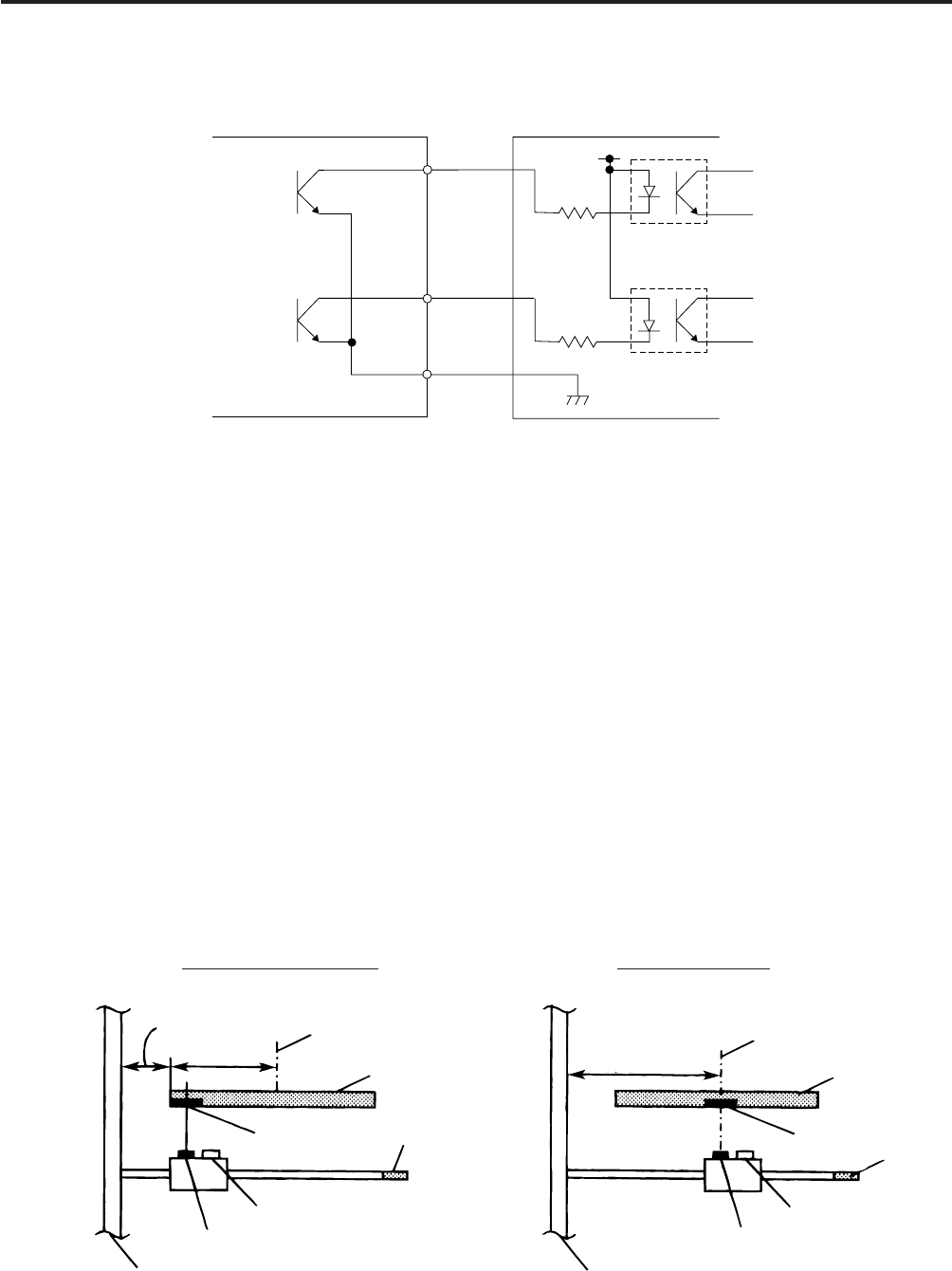

■ Output circuit

Fig. 1-9

There are six output circuits, and each output is an open collector. The voltage of Vcc is 24 V (max.)

while the operating current is 150 mA.

For other details, please refer to the Expansion I/O specification.

4) Sensor/switch

1 Head up switch (micro switch)

This switch, attached at the lower left of the print head as viewed from the media outlet, detects

that the print head is ready to print (head is down). When the head lever is lowered, the head

down cam pushes up the print head, the micro switch is turned on and the print head prepares

to print.

2 Paper sensor

This sensor is comprised of the black mark sensor and feed gap sensor. It is positioned 92.1

mm from the platen.

The sensor position is adjustable according to the media width. It moves toward the main

frame a max. of 70 mm by turning the knob counterclockwise.

■ Black mark sensor (Reflective sensor)

This sensor detects the difference of potential between the black mark and tag paper to

find the print position of the tag paper.

It is located at the home position with the tag paper or print head before shipment.

Side detection (max.) Center detection

Fig. 1-11

Fig. 1-10

20.5 mm

70 mm

Tag Paper

Center

Knob

Feed Gap Sensor

Black Mark Sensor

Main Frame

Black Mark

90.5 mm

Center

Tag Paper

Black Mark

Knob

Feed Gap Sensor

Black Mark Sensor

Main Frame