Introduction

Printing basics

980541-001 Rev. A P640i Card Printer User Guide 3

Printing basics

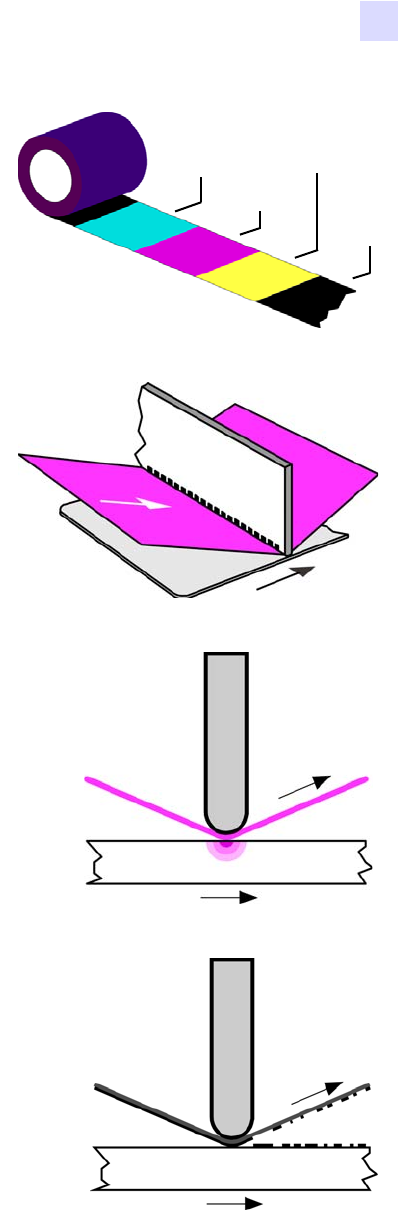

This is the usual pattern for a P640i Printer

ribbon. Y, M and C are the three “dye sub”

process colors. The K panel is for infrared-

readable bar codes and other data, usually on

the back of the card. A second K panel

(YMCKK) is sometimes provided to allow

black resin printing on both sides of the card.

As the ID card is driven through the print

station, the color ribbon is metered out from

the supply roll at the same speed. Each color

reqires a separate “pass” of the card. The black

dots at the bottom edge of the print head depict

the heating elements - in practice, at 300 to the

inch, they are too small to be seen with the

naked eye.

Color migrates from the dye ribbon onto the ID card,

the spread of the dye depending on the amount of heat

applied by the print head element. Each time it comes to

a dye panel boundary, the print head lifts to allow the

card to back up, then lowers again to print the next

color.

The K (black) panel is a resin that “mass transfers”

onto the surface of the card, instead of migrating into

it. With mass transfer the printer has little control over

a pixel’s size or density - it’s either there or it isn’t. K

printing is used for bar codes because it is machine

readable, whereas YMC dyes are not.

What makes the P640i a different kind of

printer

The print station in the P640i has no pinch rollers that need cleaning to maintain accuracy

C

Cyan

Dye

M

Magen-

ta Dye

Y

Yellow

Dye

K

Black

Resin

Print

head

Color

ribbon

Card

Card

Print

head

Card

Print

head