60 P640i Card Printer User Guide 980541-001 Rev. A

Corrective action

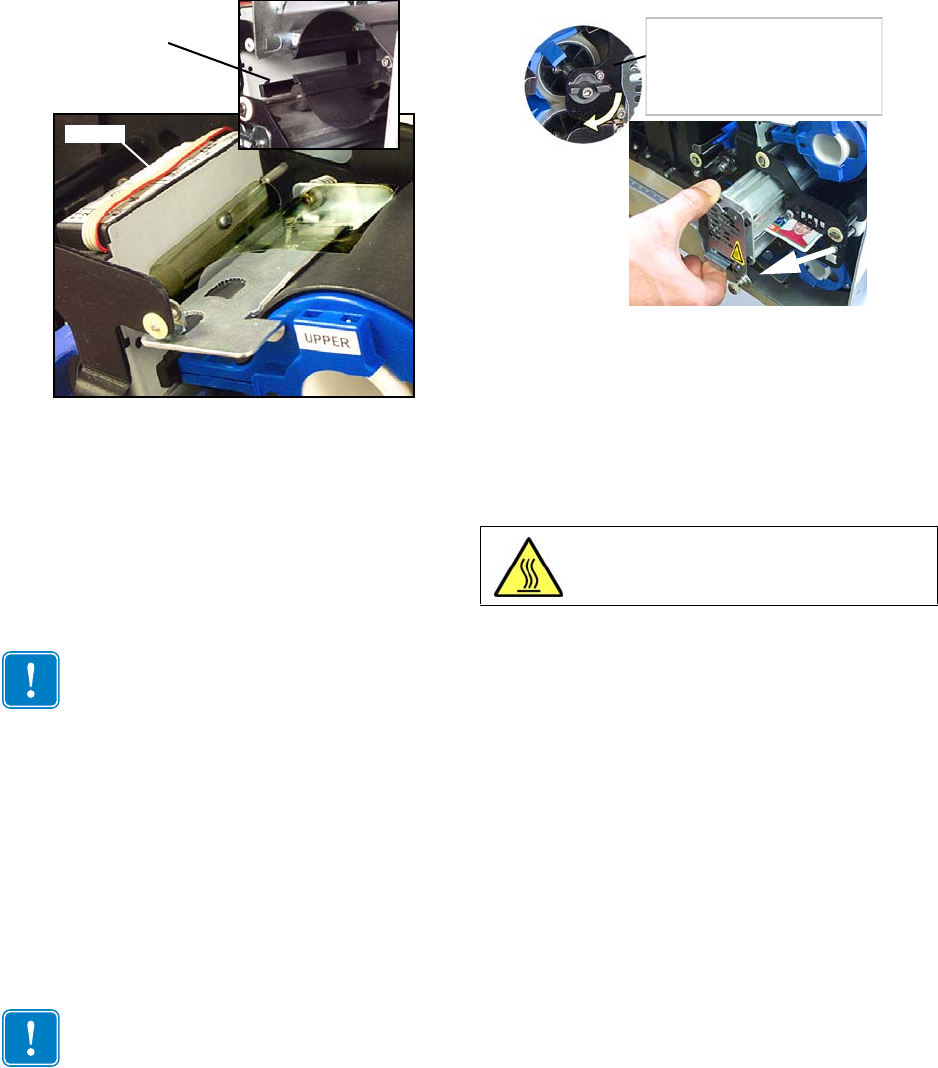

Unlatch the cassette, then gently wiggle the cassette

out of its pocket. You can make this easier by cutting

the laminate above the latch. Remove all laminate

scraps. Cut the leading edge of the fresh laminate as

square as you can with scissors, then reel it in as

described in Section 2, Media Handling. Re-install

and latch the cassette.

Problem

Card jammed in laminator. This can be caused by any

of the following:

1. Dings or rough edges on the card (depending on

vendor, card quality can vary, even from batch to

batch).

2. Either of the cutters fails to cut, so the card is

stopped dead by a “tail” of laminate, now firmly

held by the laminate feed roller, which can not be

rotated by tugging on the laminate.

3. Heated rollers not rotating.

4. Infeed rollers not rotating

5. Outfeed rollers not rotating.

Corrective action

Turn off the printer, then allow it to cool for about 10

minutes. Unscrew the heater assembly fastener, ar-

rowed, then partially withdraw the assembly together

with the card. Pull the card out of the heater, inspect

the rollers for laminate scraps and other foreign

matter, then re-install the assembly. Do NOT use metal

TOOLS to clean the rollers.

Important • Any time you unlatch a cassette, it’s

a good idea to check that the laminate is even with

the lips of the cassette before re-latching.

Important • All rollers in the main drive

train of the laminator (not the cassette

outfeeds) are connected by toothed belts.

If any of them fails to rotate, suspect loose

set screws on the toothed pulleys

Even after allowing cooling time, the assembly will

be HOT, so hold it only ny its outer cover.

Cutter feed slot

Cutter

If necessary, turn the transfer

roller toggle to separate the

transfer rollers and relieve pres-

sure on the card.