22 P640i Card Printer User Guide 980541-001 Rev. A

Troubleshooting

Troubleshooting quality problems

Troubleshooting quality problems

Poor color registration

• Minor mis-registration of Y, M and C color passes may be due to printhead angle adjust

screw not in firm contact with printhead frame. Reference Technical Note 4

• For gross mis-registration of Y, M and C suspect card not firmly against left hand pick

edge of truck on one or more passes. Spring at left end of platen may be missing or bound

up. Reference Technical Note 2

• Check printed card for damage on corners or edges. Example: the card may be scraping

along the underside of the hopper base molding. Reference Technical Note 2

• Printhead pressure too light. Reference Technical Note 4

• Printhead may be running hot. Will occur if head resistance incorrectly entered in driver

software. Reference Technical Note 4

• Toothed transport belt pulley may be slipping on drive shaft. Tighten set screws (make

sure the screws bear on flats on the shafts).

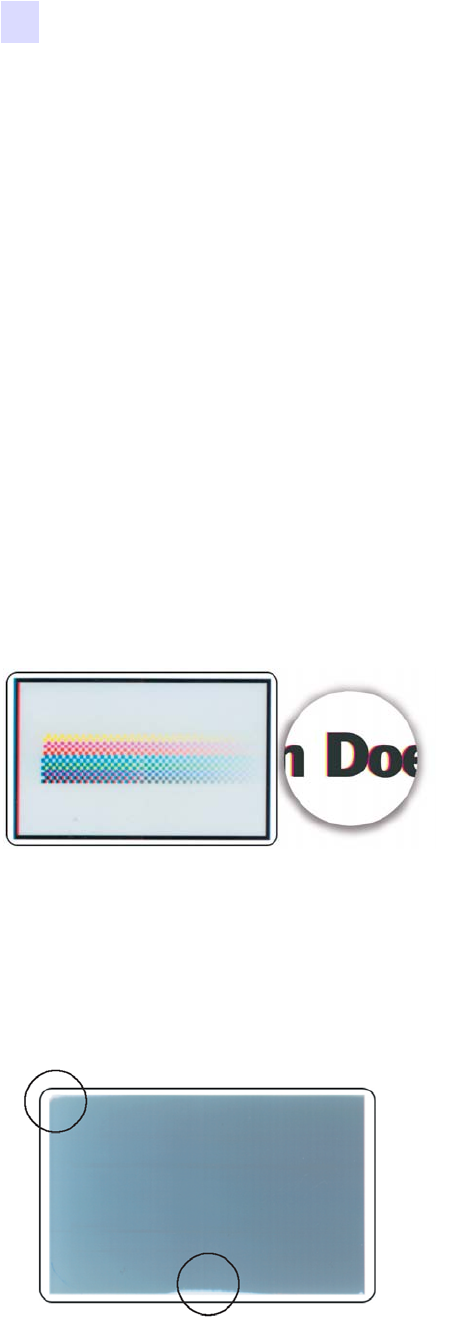

Examples of color mis-registration

Left is the test card in the printer’s firmware. Right is an enlargement showing fringing on

process black text generated from Y, M and C.

Poor color rendering

• Possible source issues - poor quality photos or

graphics, card layout application settings. Isolate

the problem by printing a known image, such as

Portraits.bmp, through IDPrint Lite. Reference

Technical Note 8

• Vary brightness and contrast controls in

Preferences > Image Adjustment (preceding

page). Fine tune if necessary using Contrast

Adjust in Properties > Device Settings > Color Calibration. Reference Technical Note 4

Faint, non-uniform image

• Printhead pressure too low. Adjust downward. Reference Technical Note 4

• Printhead not pivoting freely. Reference Technical Note 4

Gaps in image at edges and corners

• Possible de-lamination/wear of platen’s rubber surface.

Try cleaning platen. If unsuccessful, replace platen.

Reference Technical Note 2

• Possible non-uniformity of card thickness, or card surface

defects.